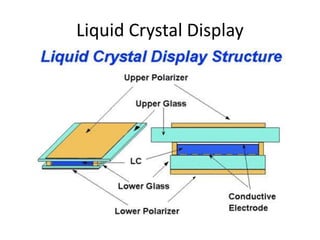

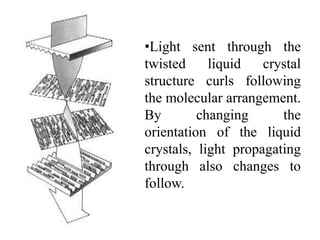

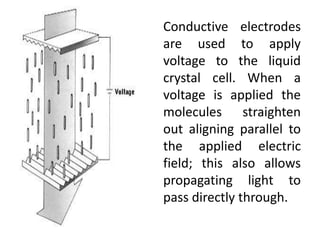

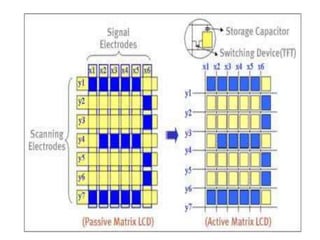

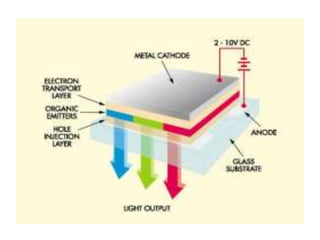

Liquid crystal displays (LCDs) are the most common display technology. They work by manipulating the orientation of liquid crystals, which allows light to pass through polarized lenses. LCDs have faster response times than older cathode ray tube (CRT) displays. Other display technologies discussed include organic light emitting diodes (OLEDs), digital light processing (DLP), and plasma display panels (PDPs). Emerging technologies like field emission displays (FEDs) aim to improve on LCD and CRT by allowing electron emission without high temperatures.