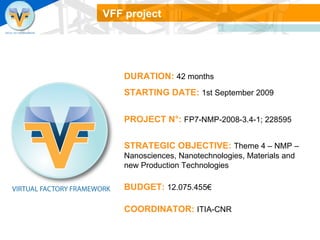

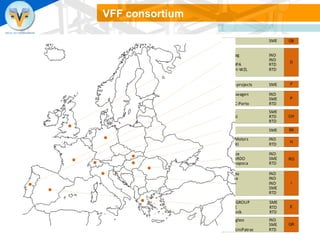

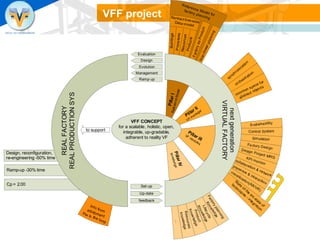

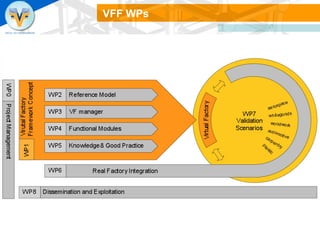

The VFF project aims to create a holistic, extensible, and scalable Virtual Factory Framework. The project has a budget of 12.075 million euros and runs from 2009 to 2012. It involves multiple partners collaborating on four pillars: technical, logistical, quality, and factory planning. The goals are to reduce costs and improve quality, flexibility, and productivity through virtual simulation and optimization of factory processes, reconfiguration, and planning.