Project Charter GTL2 _Sewing_6_June_ 2016

•Download as DOCX, PDF•

0 likes•295 views

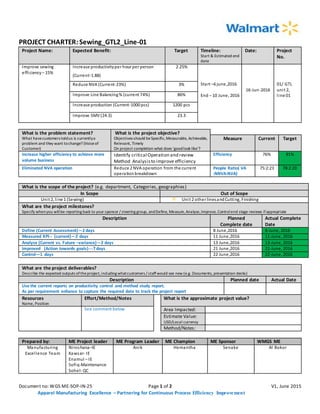

This project charter aims to improve sewing efficiency on Unit 2, line 1 by 15% and increase productivity per hour per person from 1.88 to 2.25. Specific objectives include reducing non-value-added time from 23% to 20%, improving line balancing from 74% to 86%, and increasing production from 1000 to 1200 pieces. The scope is Unit 2, line 1 for sewing. Key milestones include defining the current assessment by June 8, measuring KPIs by June 11, analyzing results by June 13, and improving and controlling the process through June 22. Deliverables include updated productivity reports and a project report. Resources listed are manufacturing excellence team members from various roles.

Report

Share

Report

Share

Recommended

Recommended

More Related Content

What's hot

What's hot (19)

Ops 571 final exam questions and correct answers 100% guaranteed#

Ops 571 final exam questions and correct answers 100% guaranteed#

Top 10 most important manufacturing performance indicators in 2019

Top 10 most important manufacturing performance indicators in 2019

Uop ops 571 final exam guide new 2017 (score 3030) new

Uop ops 571 final exam guide new 2017 (score 3030) new

Viewers also liked

Viewers also liked (12)

Welzijnsindicatoren - stijgende belang van gedrag in de veiligheidscultuur

Welzijnsindicatoren - stijgende belang van gedrag in de veiligheidscultuur

Comunicat de presa activitati culturale luna aprilie

Comunicat de presa activitati culturale luna aprilie

Supuesto no autocorrelación de análisis de regresion

Supuesto no autocorrelación de análisis de regresion

Similar to Project Charter GTL2 _Sewing_6_June_ 2016

Similar to Project Charter GTL2 _Sewing_6_June_ 2016 (20)

IMPROVING OSH & PRODUCTIVITY OF RMG INDUSTRIES BY IMPLEMENTING LEAN TOOLS AN...

IMPROVING OSH & PRODUCTIVITY OF RMG INDUSTRIES BY IMPLEMENTING LEAN TOOLS AN...

IRJET- Enhance the Capacity of Outer Tube Machining Cell

IRJET- Enhance the Capacity of Outer Tube Machining Cell

Software Solution for Production Planning and Scheduling

Software Solution for Production Planning and Scheduling

Line Balancing and facility optimization of Machine Shop with Work Study and ...

Line Balancing and facility optimization of Machine Shop with Work Study and ...

IRJET - Analysis of Process Re-Engineering to Reduce Lead Time in Apparel Ind...

IRJET - Analysis of Process Re-Engineering to Reduce Lead Time in Apparel Ind...

Quality Function Deployment in Construction Industry

Quality Function Deployment in Construction Industry

Manufacturing Lead Time Reduction in Monoblock (SWJ) Pump Industry [irjet-v4 ...

Manufacturing Lead Time Reduction in Monoblock (SWJ) Pump Industry [irjet-v4 ...

Manufacturing Lead Time Reduction in Monoblock (SWJ) Pump Industry

Manufacturing Lead Time Reduction in Monoblock (SWJ) Pump Industry

More from Anik Mazumdar

More from Anik Mazumdar (7)

Manufacturing Excellence Line- Efficiency Improvement Project

Manufacturing Excellence Line- Efficiency Improvement Project

Project Charter GTL2 _Sewing_6_June_ 2016

- 1. Document no: WGS ME-SOP-IN-25 Page 1 of 2 V1, June 2015 Apparel Manufacturing Excellence – Partnering for Continuous Process Efficiency Improvement PROJECT CHARTER:Sewing_GTL2_Line-01 Project Name: Expected Benefit: Target Timeline: Start & Estimated end date Date: Project No. Improve sewing efficiency– 15% Increase productivityper hour per person (Current-1.88) 2.25% Start –6 june,2016 End – 10 June, 2016 16-Jun-2016 01/ GTL unit 2, line 01 Reduce NVA (Current-23%) 3% Improve Line Balancing% (current 74%) 86% Increase production (Current-1000 pcs) 1200 pcs Improve SMV (24.3) 23.3 What is the problem statement? What havecustomers toldus is currentlya problem and they want tochange? (Voiceof Customer) What is the project objective? Objectives should beSpecific,Measurable, Achievable, Relevant, Timely On project completion what does ‘goodlook like’? Measure Current Target Increase higher efficiency to achieve more volume business Identify critical Operation and review Method Analysisto improve efficiency Efficiency 76% 91% Eliminated NVA operation Reduce 2 NVA operation from the current operationbreakdown People Ratio( VA :NNVA:NVA) 75:2:23 78:2:20 What is the scope of the project? (e.g. department, Categories, geographies) In Scope Out of Scope Unit 2, line 1 (Sewing) Unit 2 other linesand Cutting, Finishing What are the project milestones? Specify whenyou willbe reporting back to your sponsor / steering group, andDefine, Measure,Analyse,Improve, Controlend stage reviews ifappropriate Description Planned Complete date Actual Complete Date Define (Current Assessment)—2 days 8 June,2016 8-June, 2016 Measured KPI-- (current)—2 days 11 June,2016 11-June, 2016 Analyse (Current vs. Future –variance)—2 days 13 June,2016 13-June, 2016 Improved (Action towards goals)---7 days 21 June,2016 21-June, 2016 Control—1 days 22 June,2016 22-June, 2016 What are the project deliverables? Describe the expected outputs oftheproject,including whatcustomers / staffwould see new (e.g. Documents, presentation decks) Description Planned date Actual Date Use the current reports on productivity control and method study report. As per requirement enhance to capture the required data to track the project report Resources Name, Position Effort/Method/Notes What is the approximate project value? See comment below Area Impacted: Estimate Value: USD/Local currency Method/Notes: Prepared by: ME Project leader ME Program Leader ME Champion ME Sponsor WMGS ME Manufacturing Excellence Team Niroshana–IE Kawsar- IE Enamul – IE Sofiq-Maintenance Sohel- QC Anik Hemantha Senake Al Bokor

- 2. Document no: WGS ME-SOP-IN-25 Page 2 of 2 V1, June 2015 Apparel Manufacturing Excellence – Partnering for Continuous Process Efficiency Improvement Improvement - Action Points Bottleneck operation identify based on set target 120 pcs/hr. Attach Sleeve Tape/Gamble Method change. Cuff turn Method change. Cuff top stitch 1.4 method change & balancewith Hem cuff. Side seam, cuff joint,BH operation method change. Shoulder T/s operation method change & MachineRPM change. Press waistbelt capacity increased by increasingfolder. Loop mark operation eliminate by laser light. Work on linebalancingbaseon capacity graph as increaselineefficiency Excess Materials movement eliminateby layoutchange. Box & cross stitch operation extra thread cutting time eliminate. Button attach operation method change. Care label tack atfront operation try adjustwith Sideseam. Cuff squareMethod change & reduce 0.5. Button attach on sleeve operator sleeve placketcut process balancewith sleeve placket mark. **The purpose of this document is to help project managers communicate key projectinformation to their sponsors