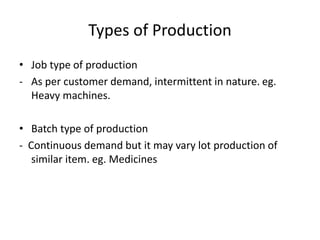

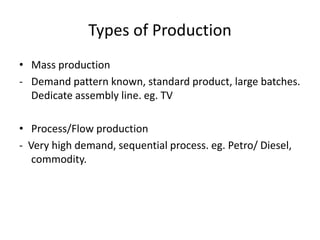

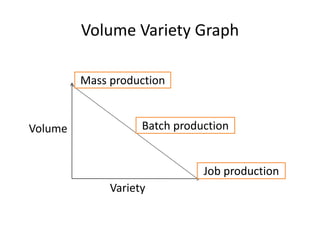

This document discusses production planning and control (PPC). PPC aims to design systems to meet quality standards through all stages of production from raw materials to finished goods. It helps forecast sales and costs, receives orders, and translates requirements into manpower, machine, and material needs. PPC activities include production scheduling, ensuring availability of facilities, and assigning jobs to workers and machines. There are different methods and types of production including job, batch, mass, and flow production. PPC follows 10 commandments related to materials, machines, methods, routing, scheduling, dispatching, expediting, inspection, estimation, and evaluation.

![10 Commandment of PPC

• Material: As required.

• Machines: Out sources.

• Methods: Which method, which technology.

• Routing: Job.

• Scheduling: Which job for which day.

• Dispatching: [All clear signal]

• Expediting: Follow up at fast manner.

• Inspection: Like raw material inspection all kind of

inspection like quality.

• Estimation: Time that is to be set to operation.

• Evaluation: Whether the product/ job done is proper.

( communication department is important)](https://image.slidesharecdn.com/productionplaningcontrol-190527024954/85/Production-planing-control-10-320.jpg)