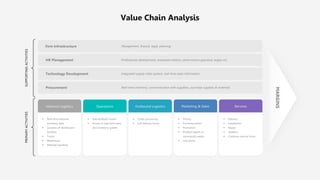

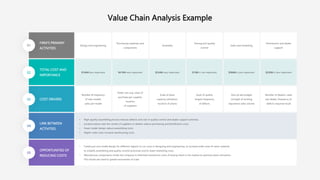

This value chain analysis examines the primary and supporting activities of a large e-commerce company. The primary activities include inbound logistics like inventory management and fulfillment centers, operations like marketplace operations and packaging, outbound logistics like order fulfillment and dispatch, marketing and sales like promotions and customer services, and services like customer support. The supporting activities include human resources, technology development like AI and AWS, procurement, finance, and legal functions. The analysis highlights how the activities work together to deliver customer value in a low-cost and customer-centric manner.