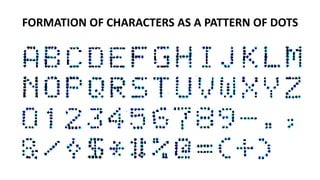

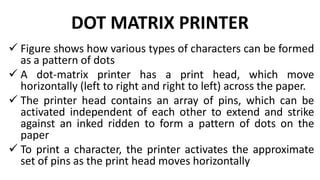

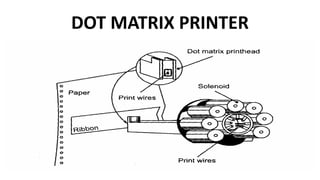

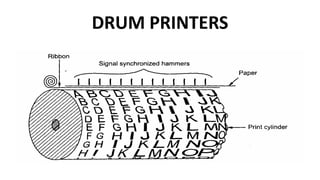

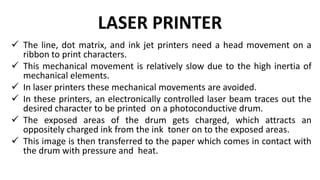

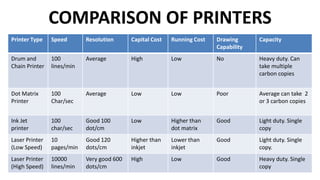

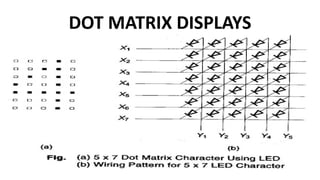

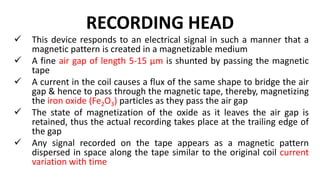

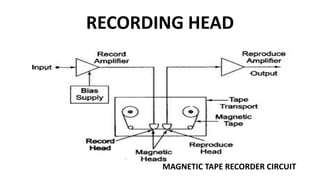

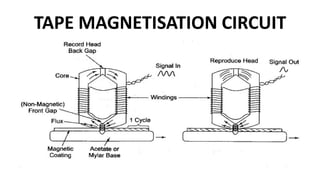

Magnetic tape recorders are widely used in instrumentation systems to record data over long periods of time. They work by using a recording head to magnetize iron oxide particles on a magnetic tape as it passes through an air gap, encoding the signal. The same tape can then be played back through a reproducing head, which detects the magnetic patterns and converts them back to the original electrical signal. Dot matrix printers form characters and images as patterns of dots by selectively activating pins in the print head. Drum printers print one line at a time using a rotating drum with embossed characters that are struck by hammers to transfer ink to paper.

![X-Y RECORDER

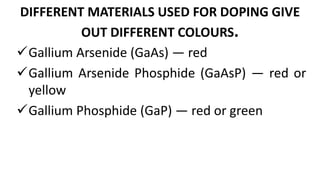

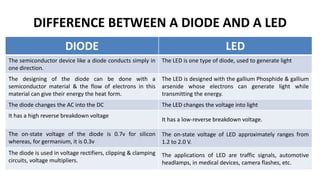

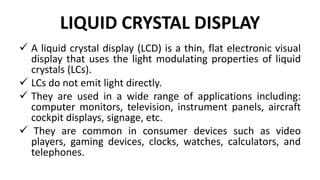

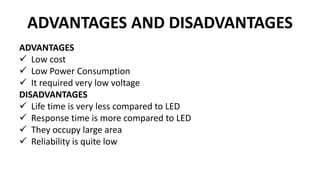

XY Recorder Working – In most research fields, it is often

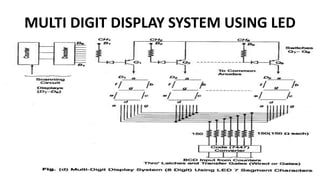

convenient to plot the instantaneous relationship between

two variables [Y = f(x)], rather than to plot each variable

separately as a function of time.

In such cases, the X—Y recorder is used, in which one

variable is plotted against another variable. In an analog

X—Y recorder, the writing head is deflected in either the x-

direction or the y-direction on a fixed graph chart paper.

The graph paper used is generally squared shaped, and is

held fixed by electrostatic attraction or by vacuum.](https://image.slidesharecdn.com/unitiii-storageanddisplaydevices-211123043633/85/storage-and-display-devices-14-320.jpg)