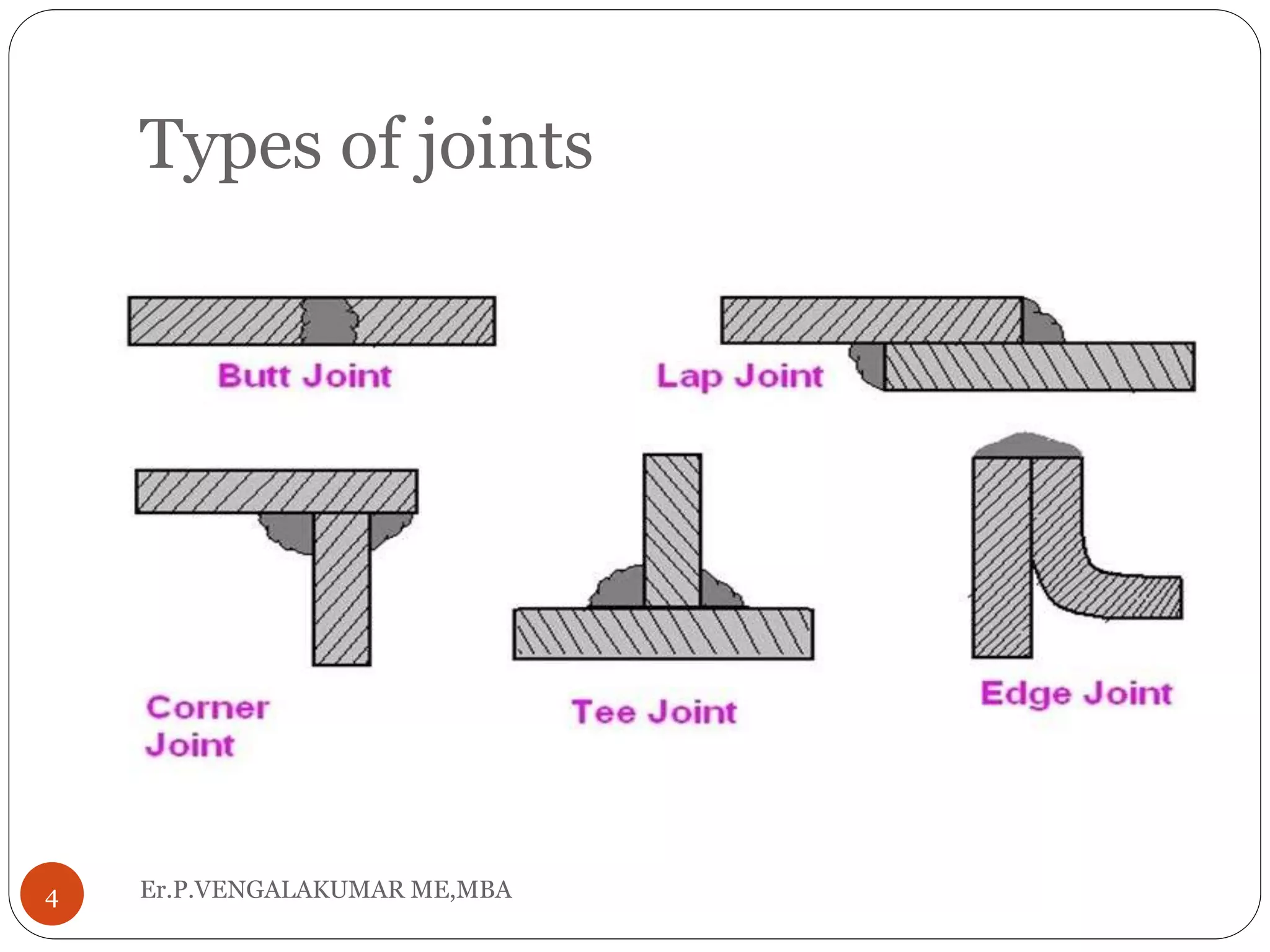

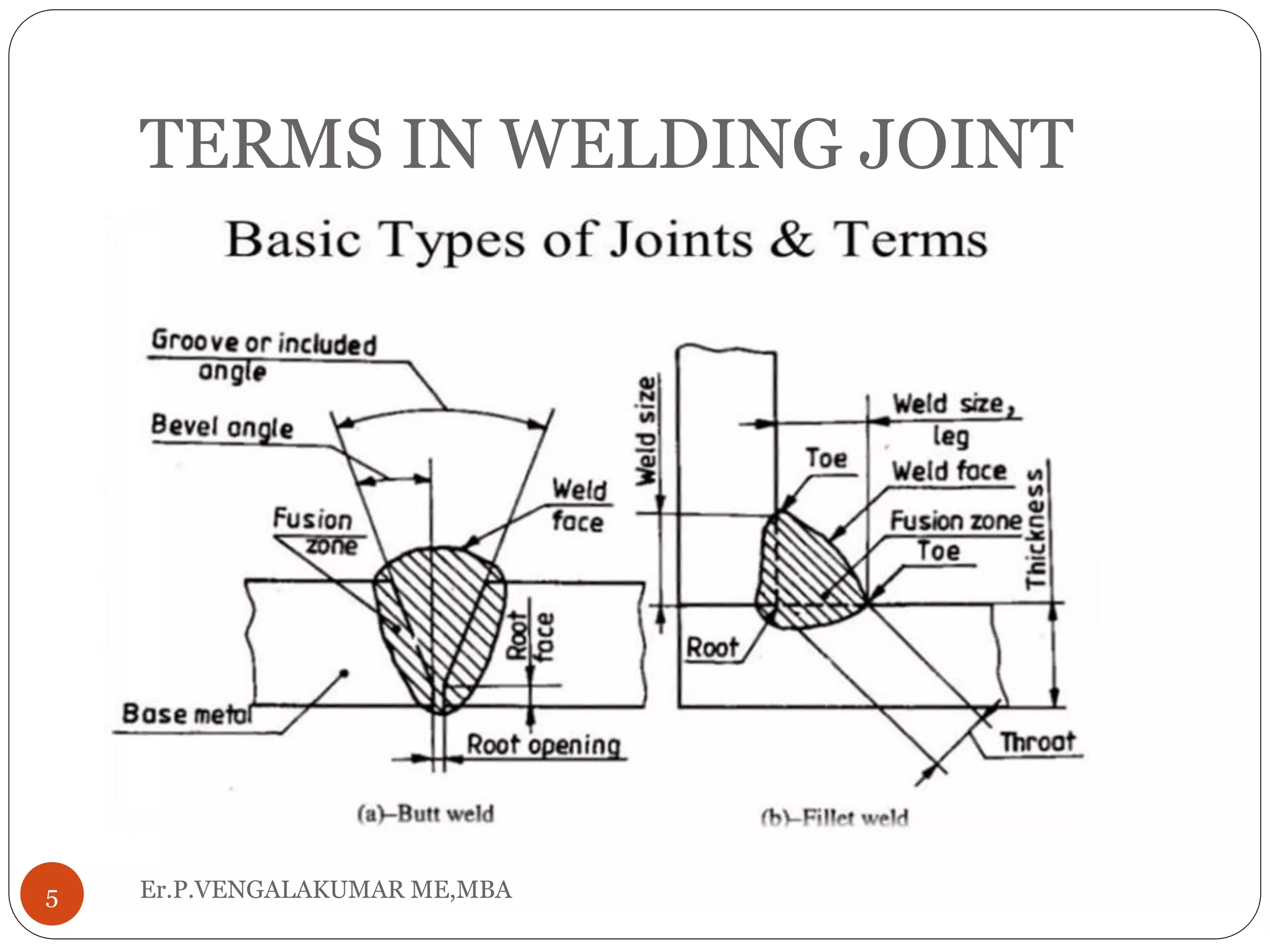

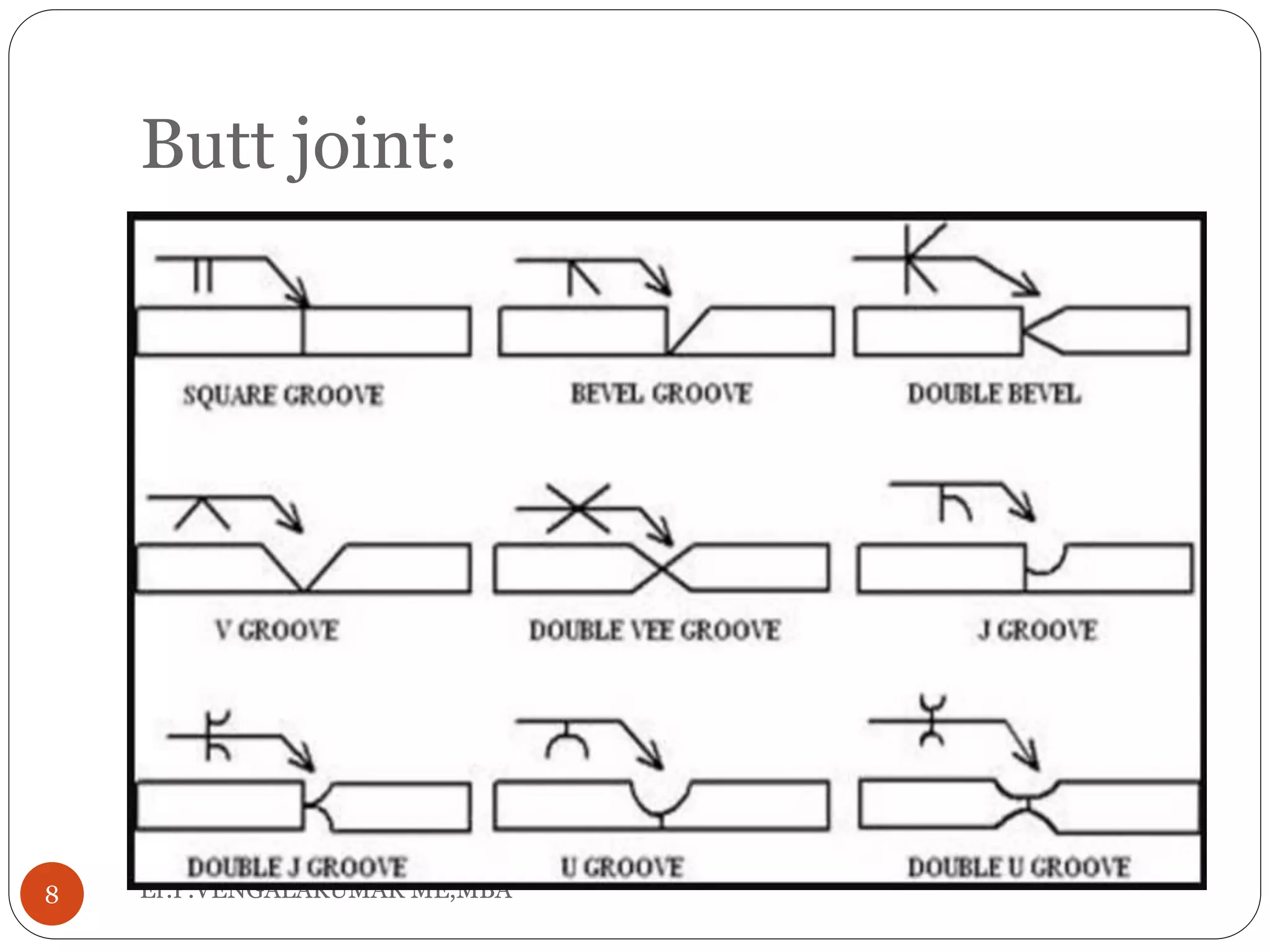

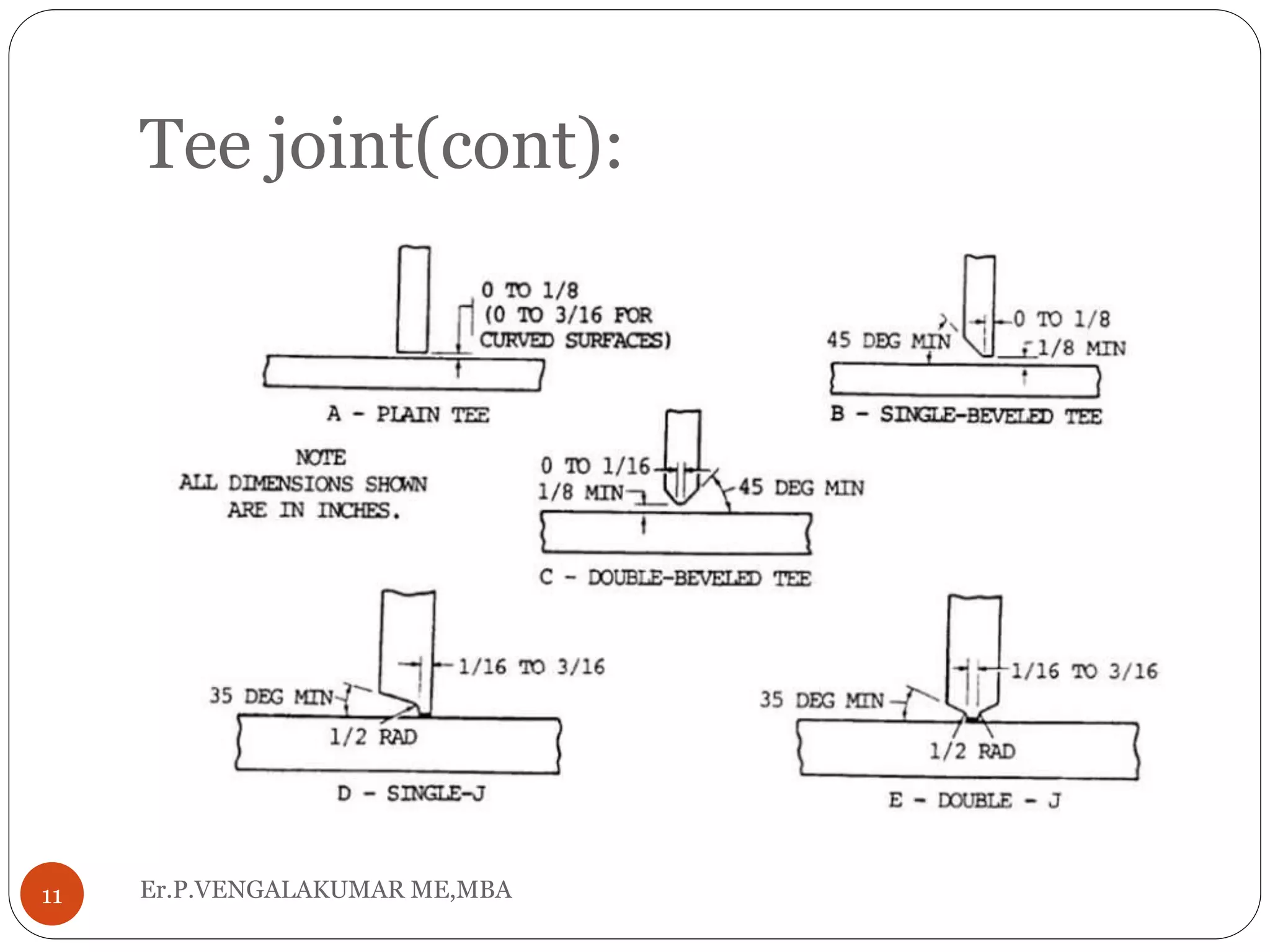

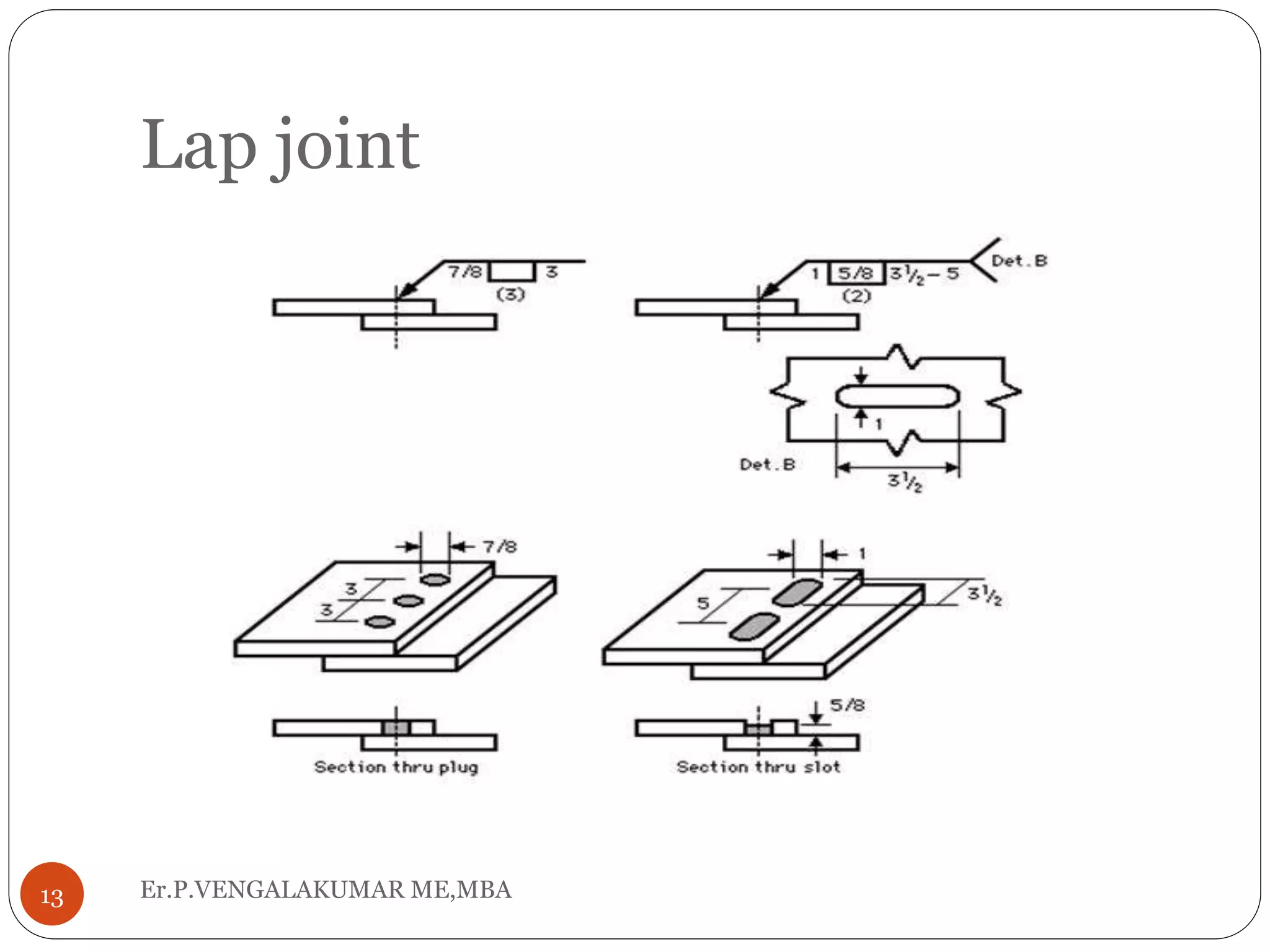

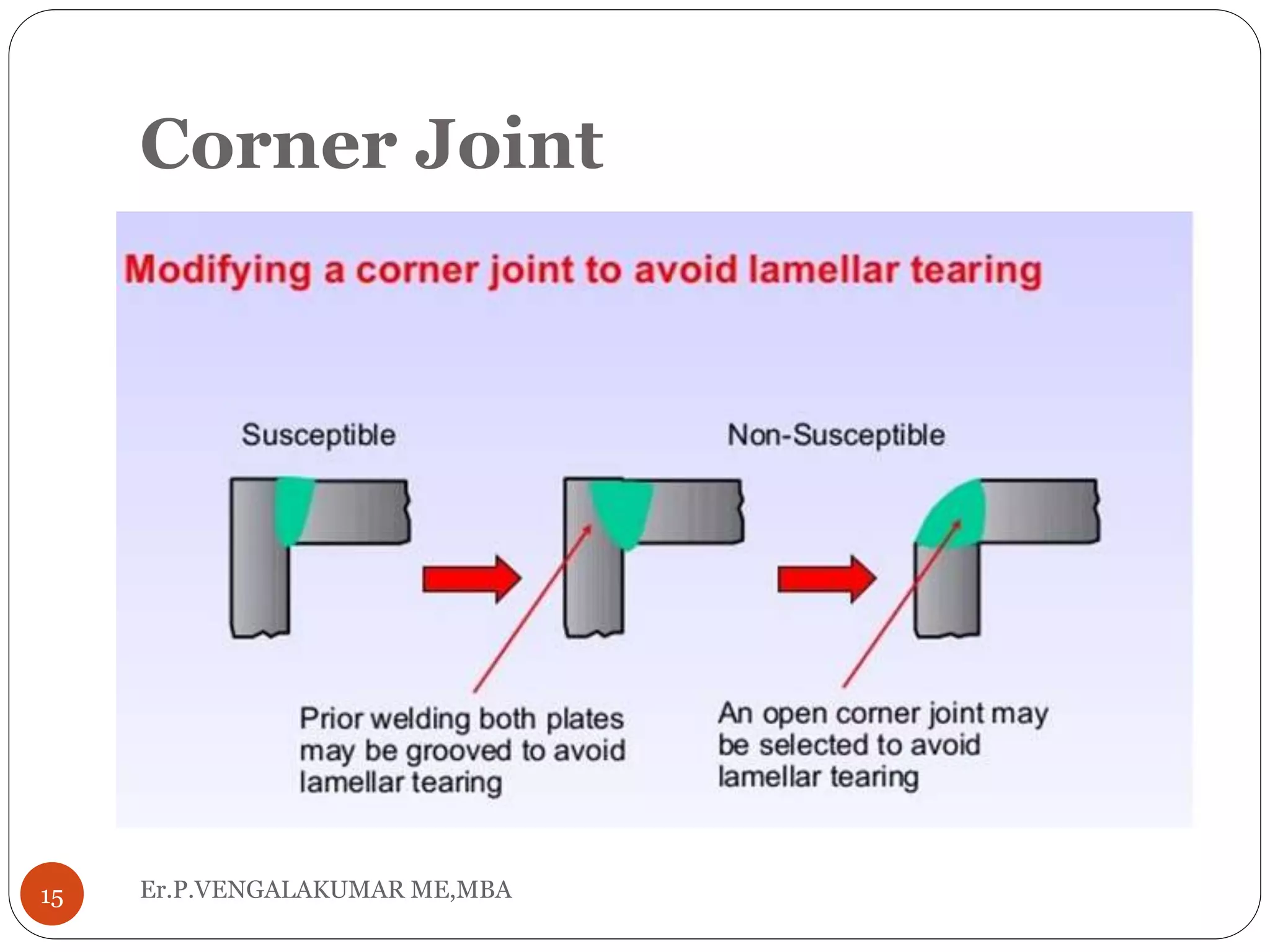

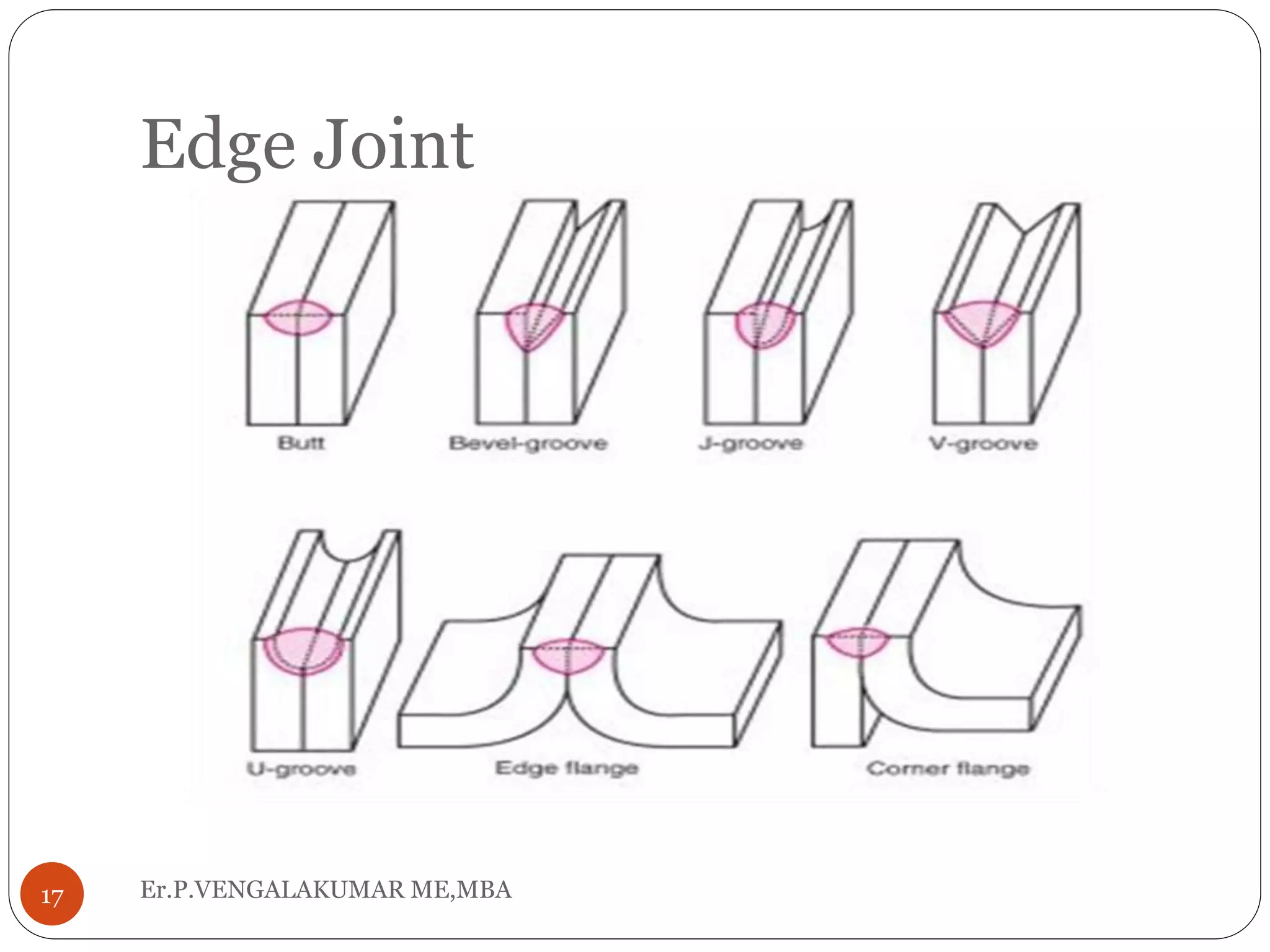

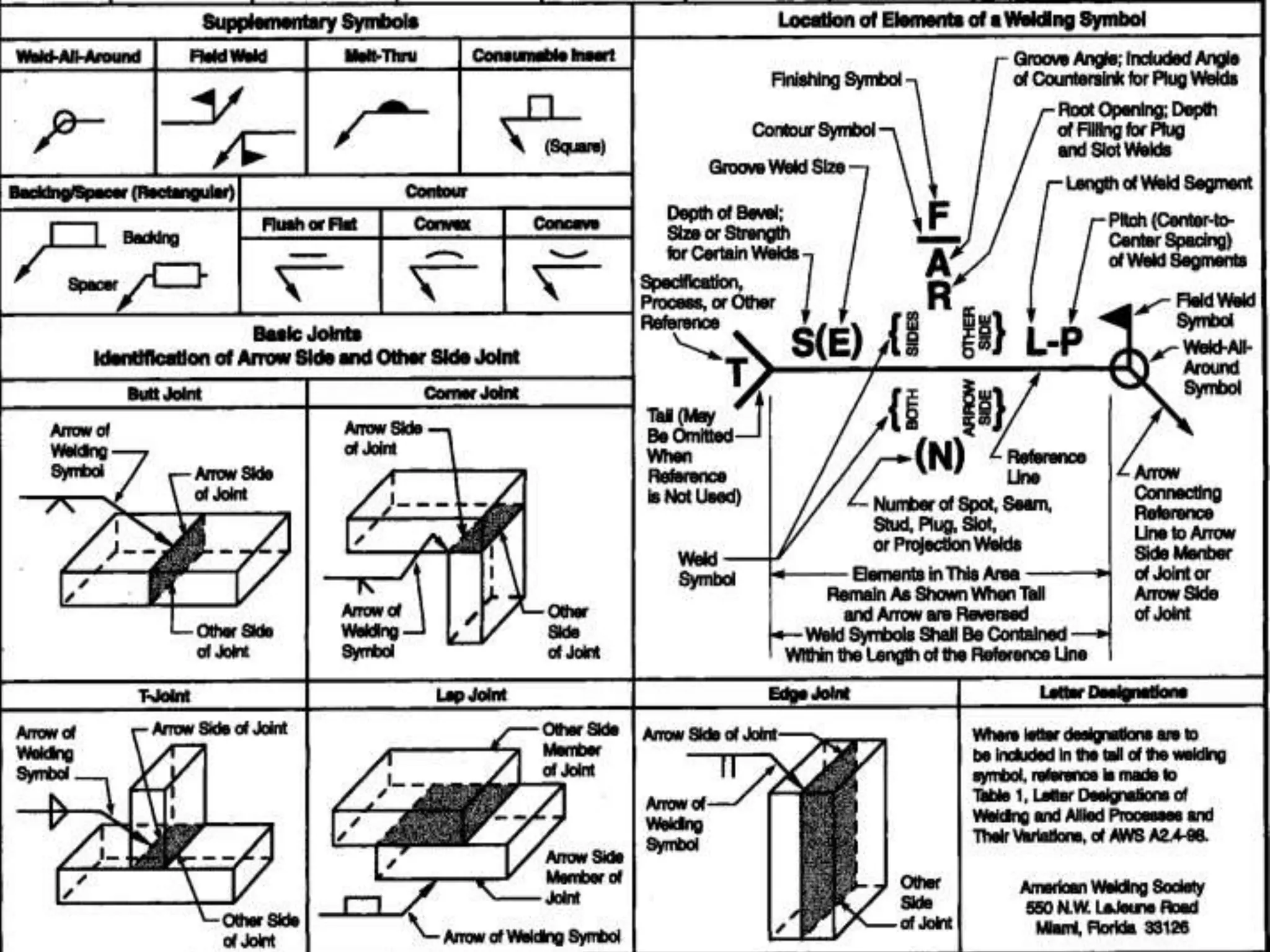

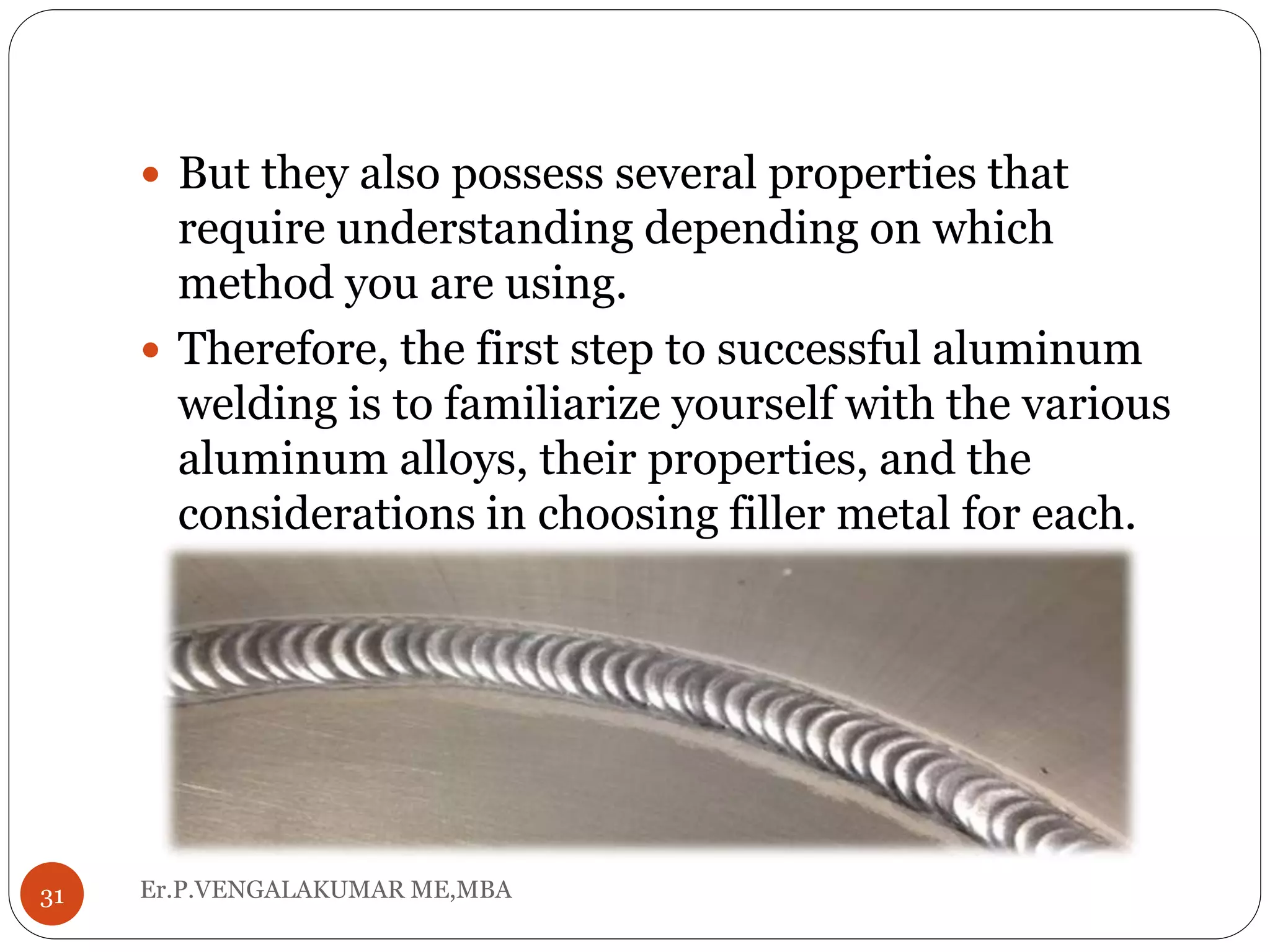

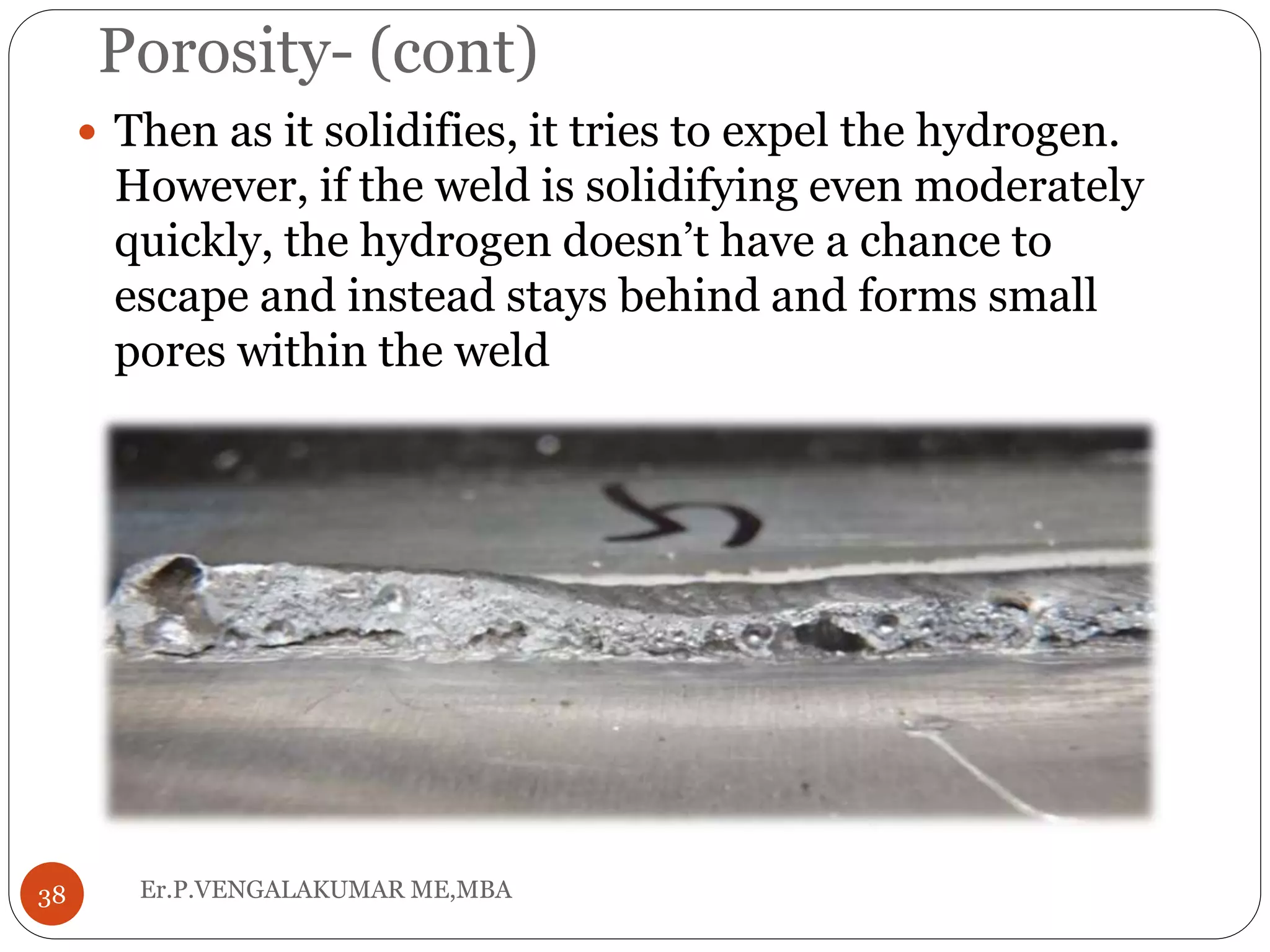

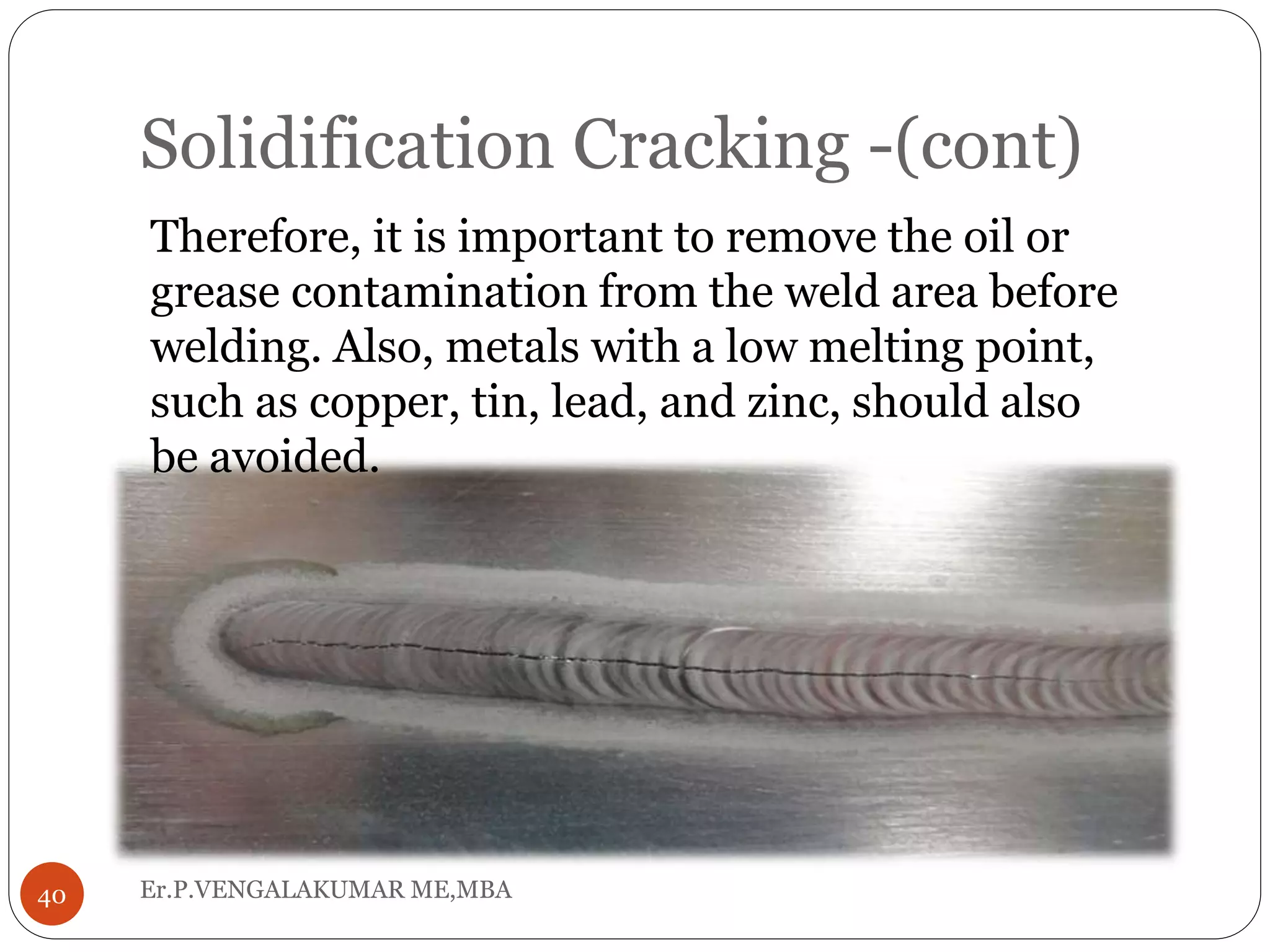

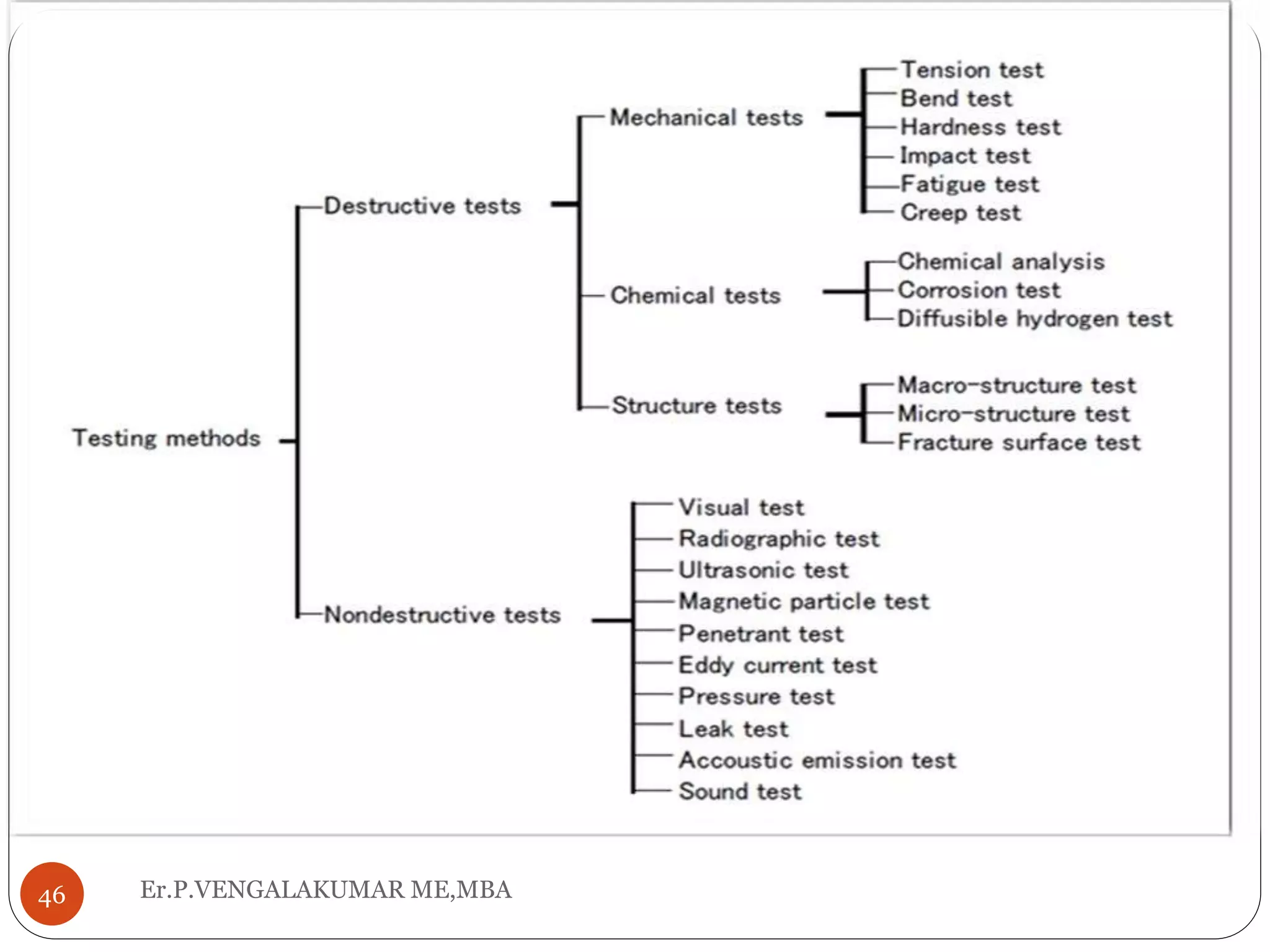

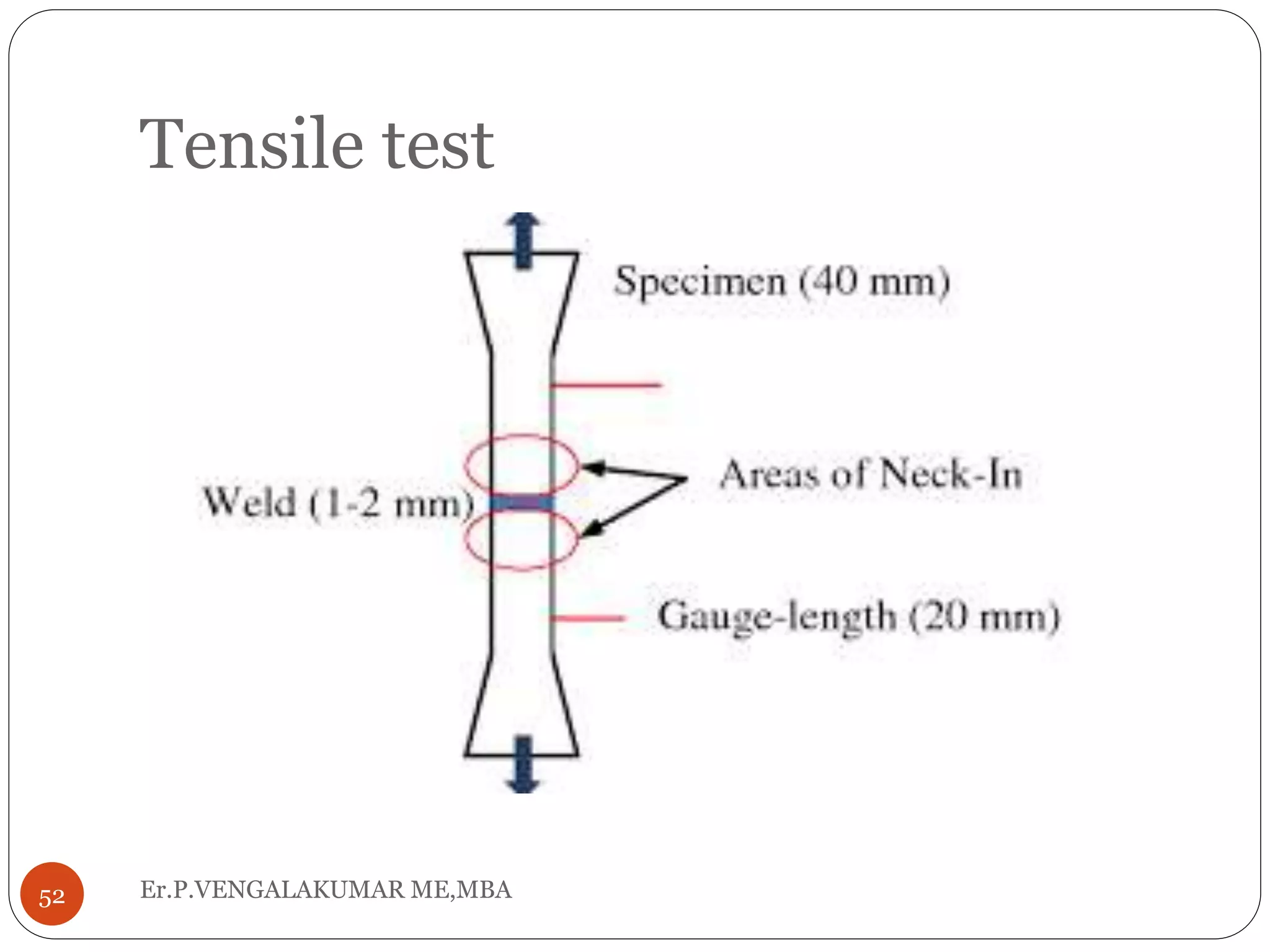

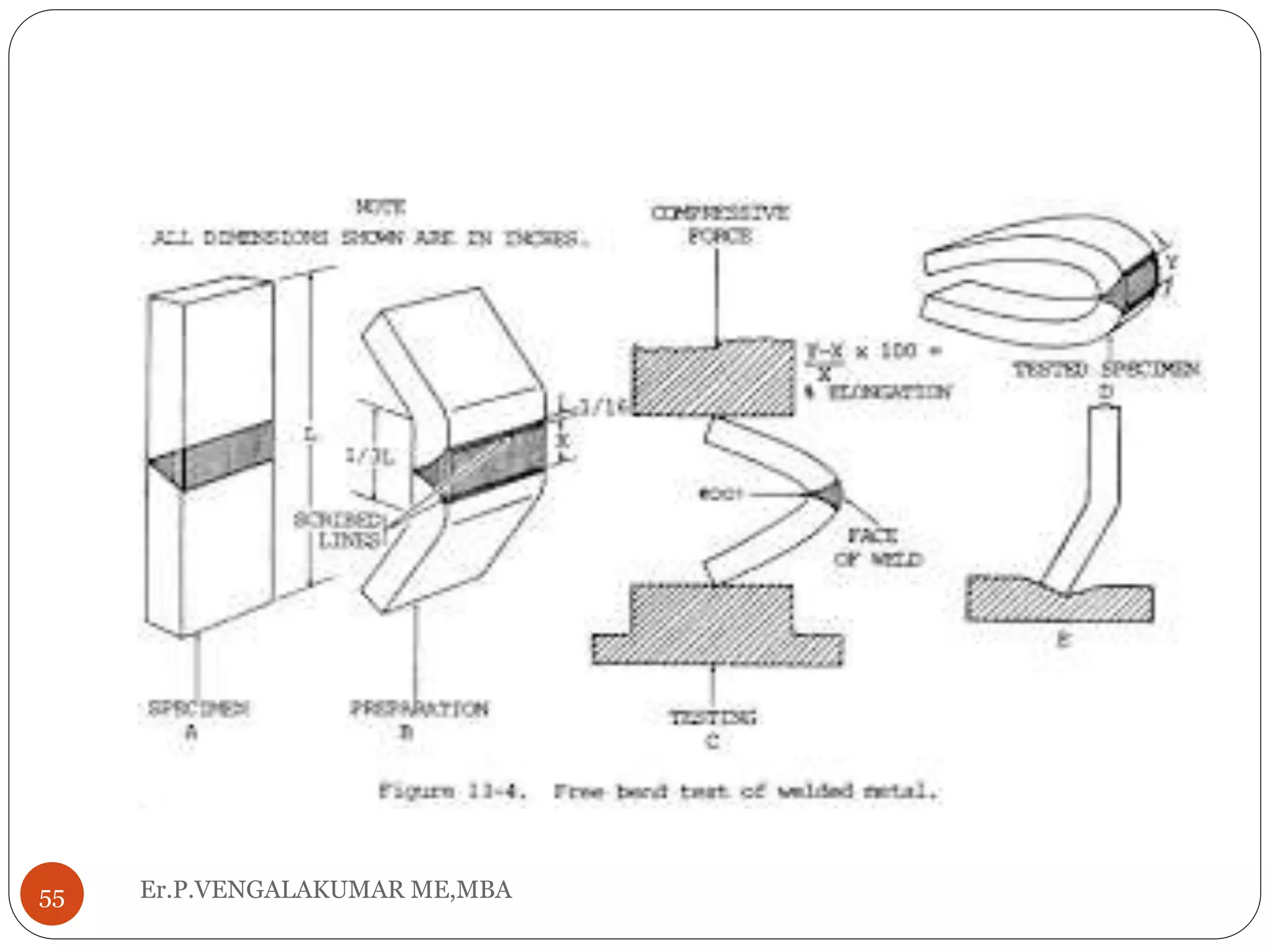

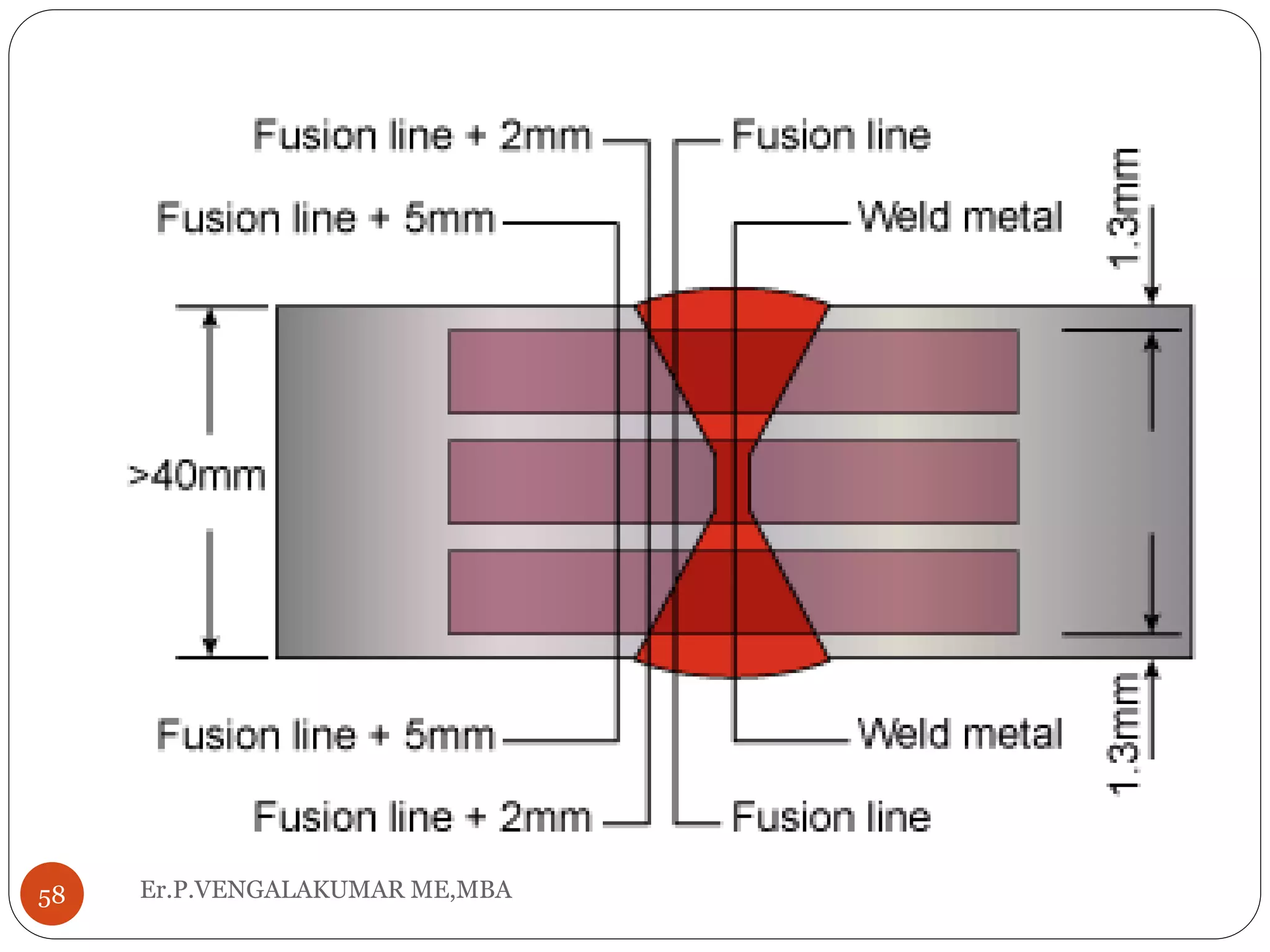

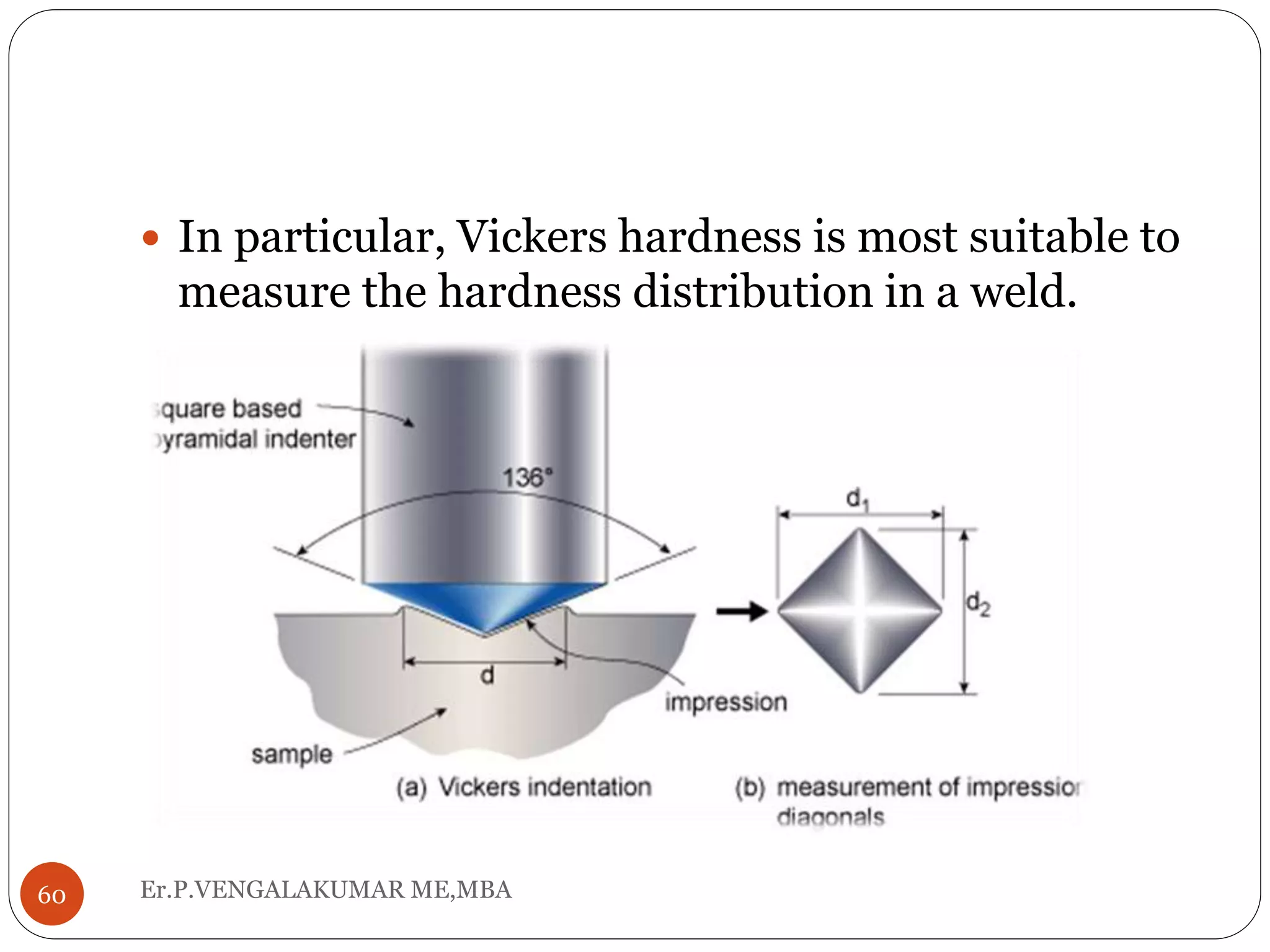

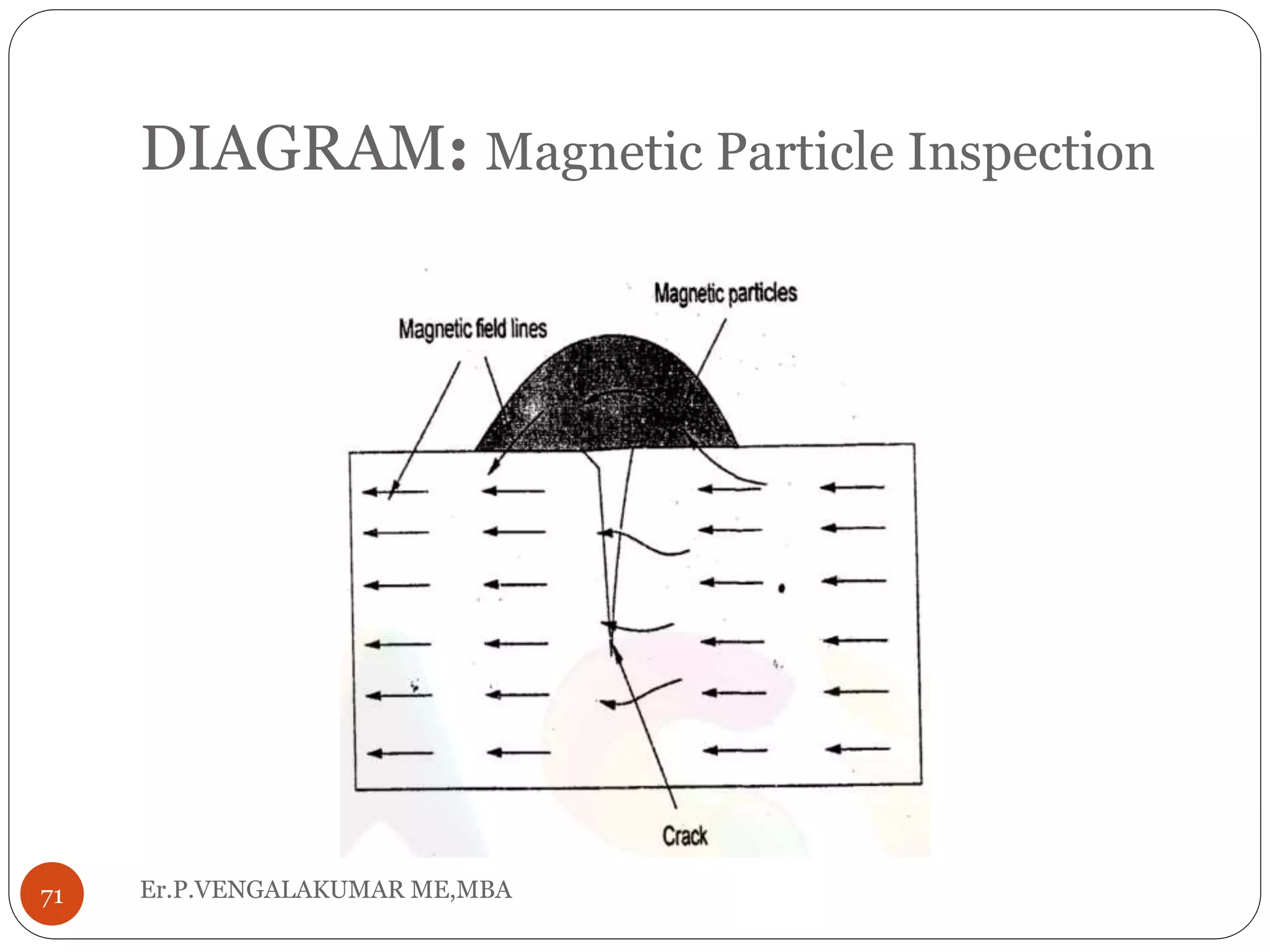

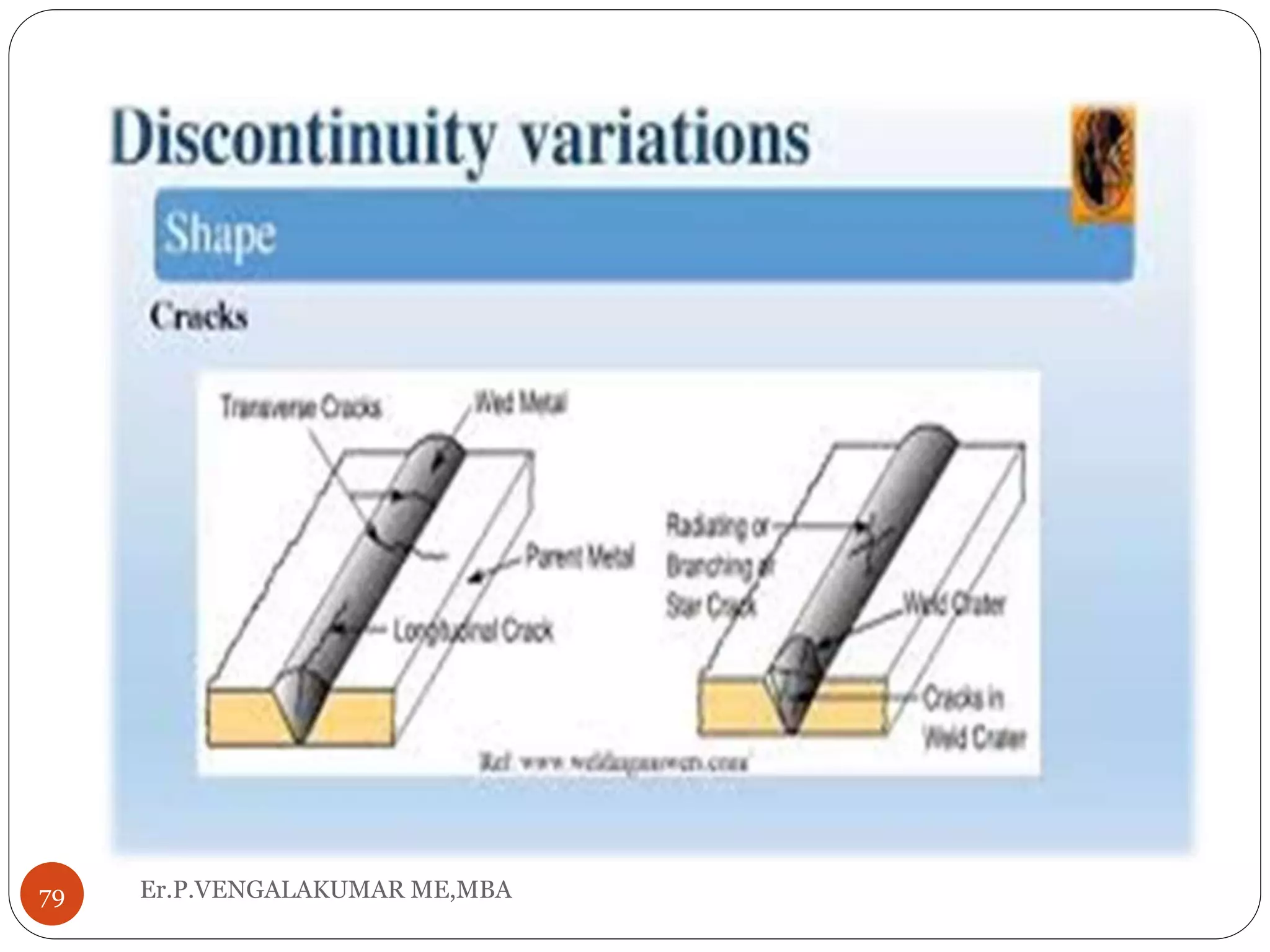

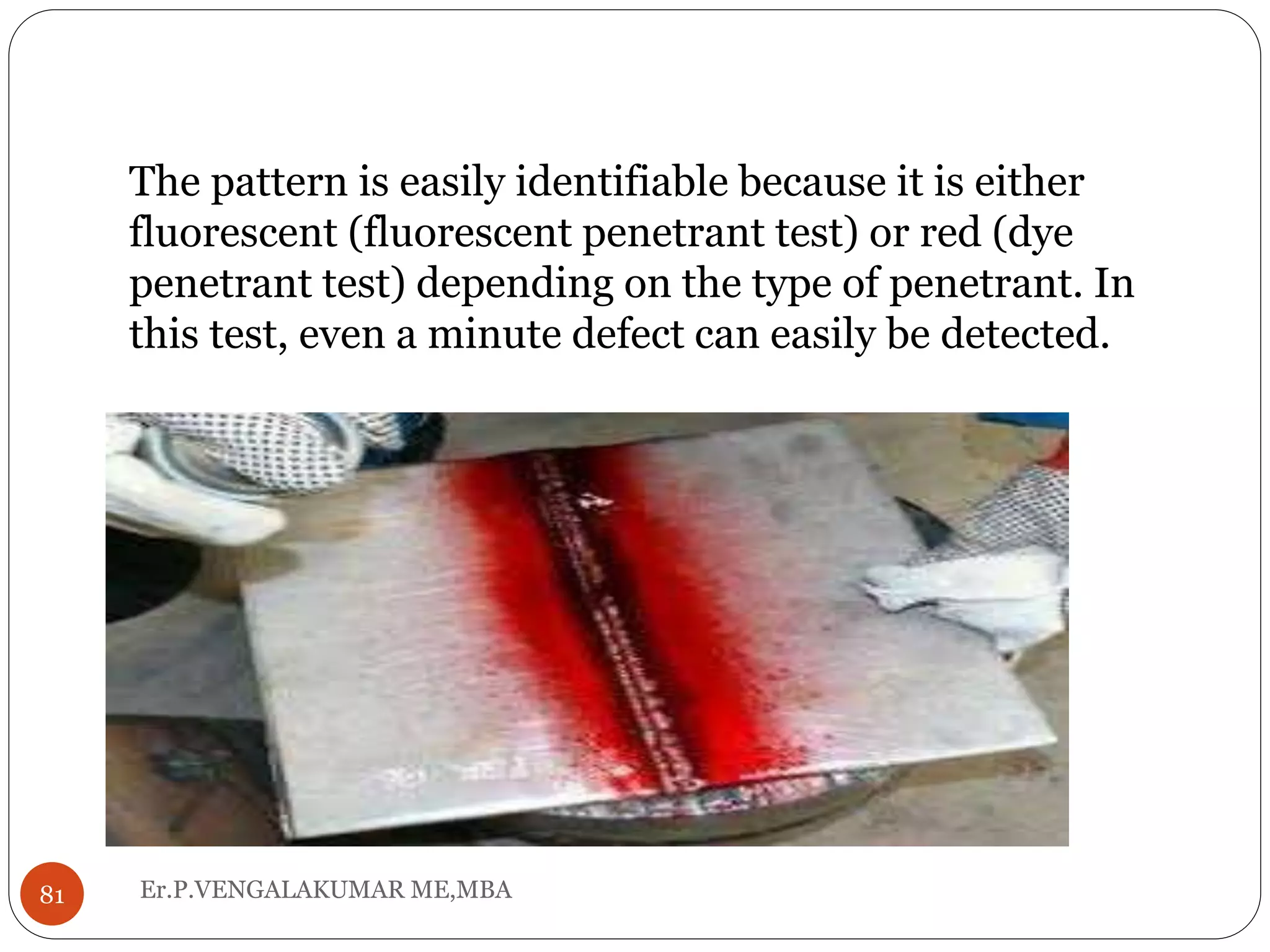

The document provides an overview of welding technology, focusing on design, weld joints, material weldability, and common defects. It details various types of weld joints, including butt, tee, lap, corner, and edge joints, along with specifics about welding metals like aluminum, copper, and stainless steel. Additionally, it covers destructive and non-destructive testing methods for welded joints to ensure quality and structural integrity.