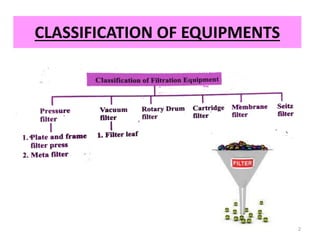

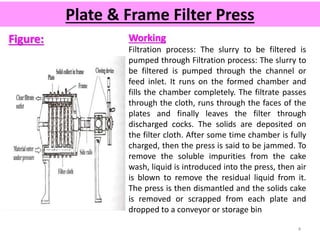

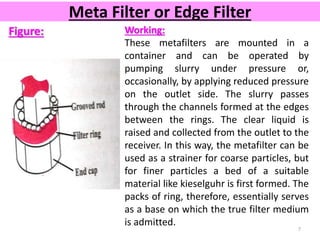

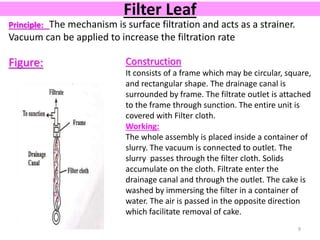

This document discusses different types of filtration equipment used in industrial processes. It describes the plate and frame filter press, which consists of alternating plates and frames that allow slurry to pass through a filter medium and collect filtrate. It also describes the metafilter or edge filter, which uses stacked metal rings to form channels for filtration. Finally, it discusses the filter leaf, which uses a framed filter cloth to filter slurry by applying a vacuum.