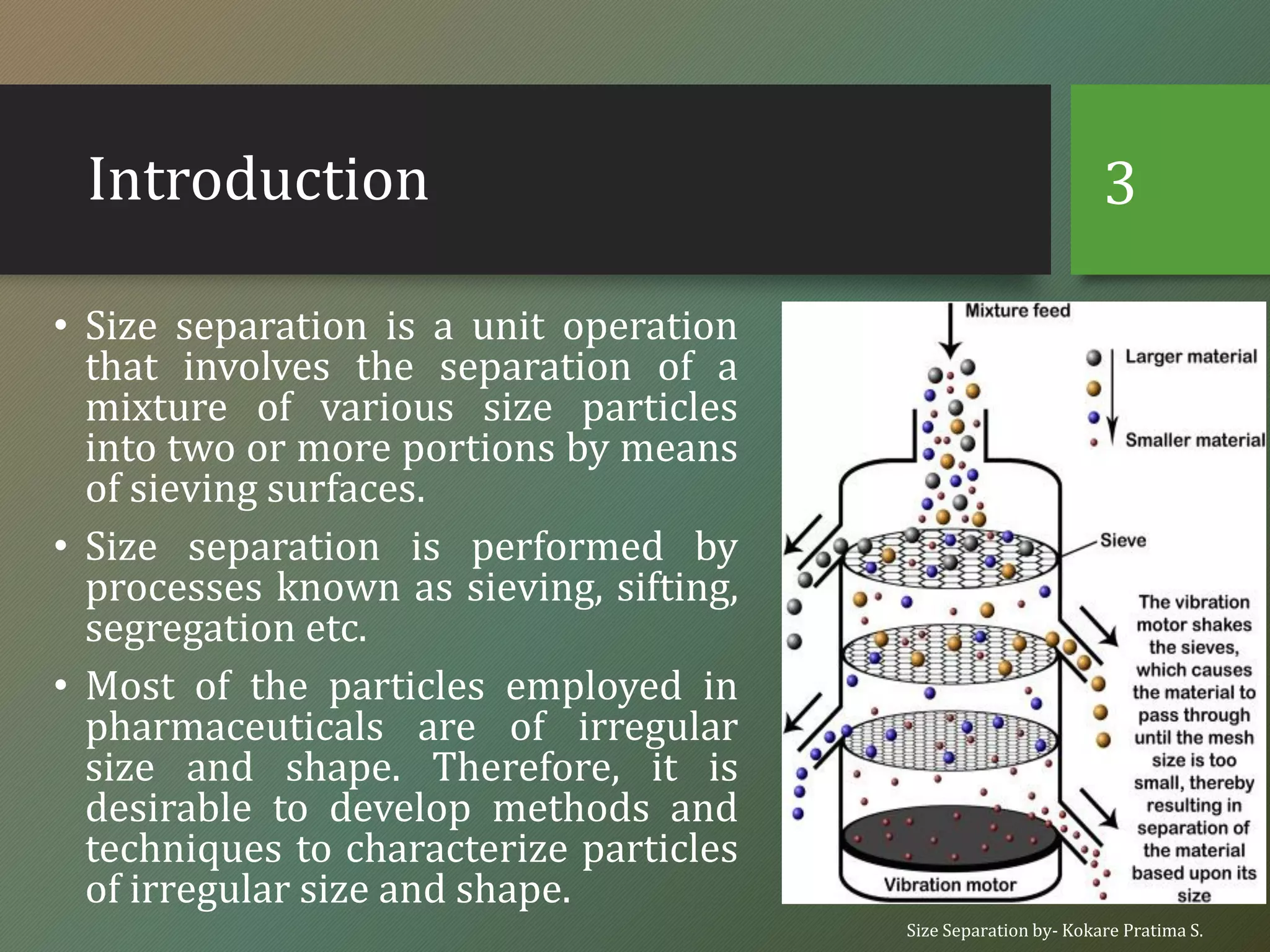

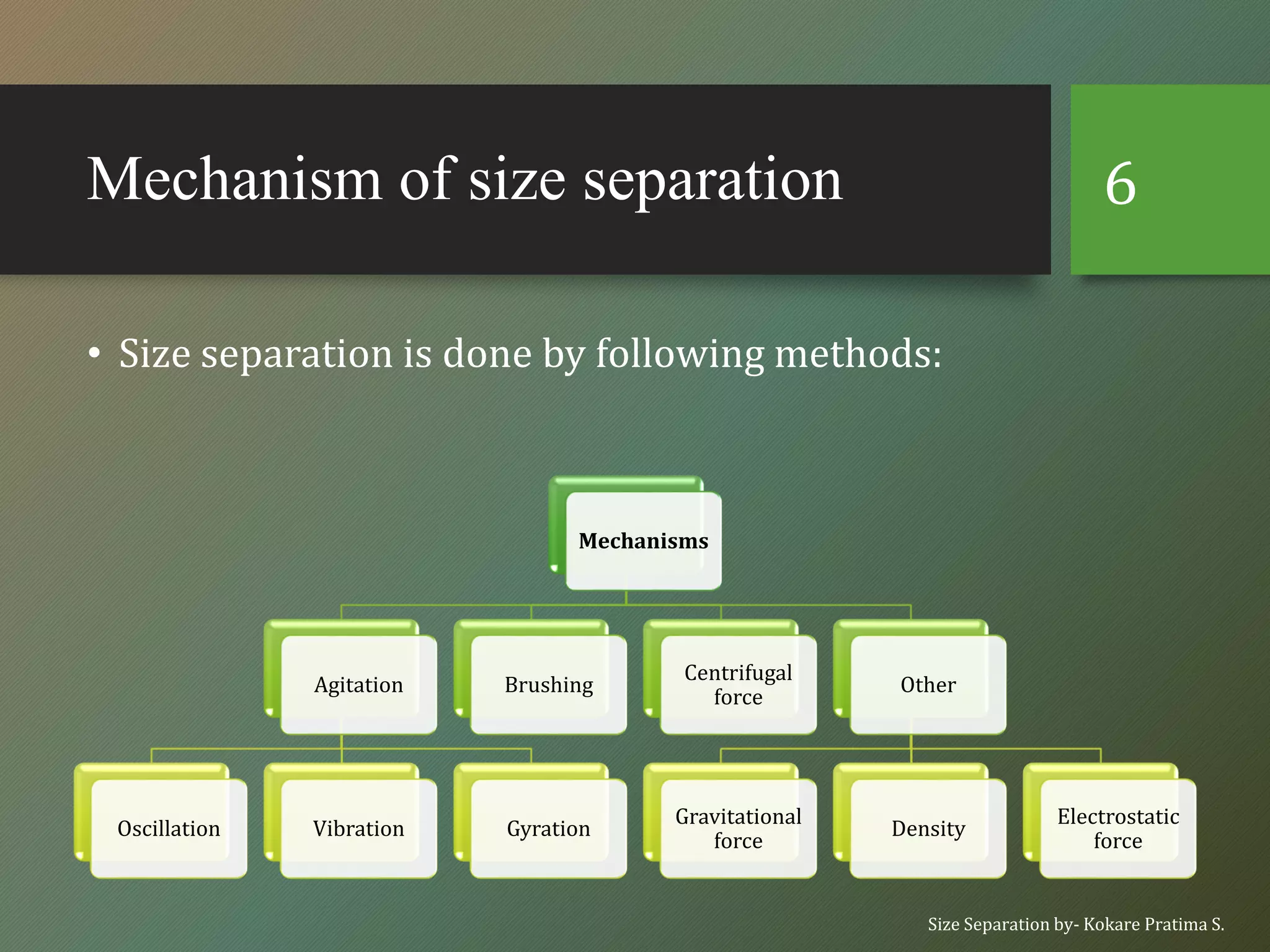

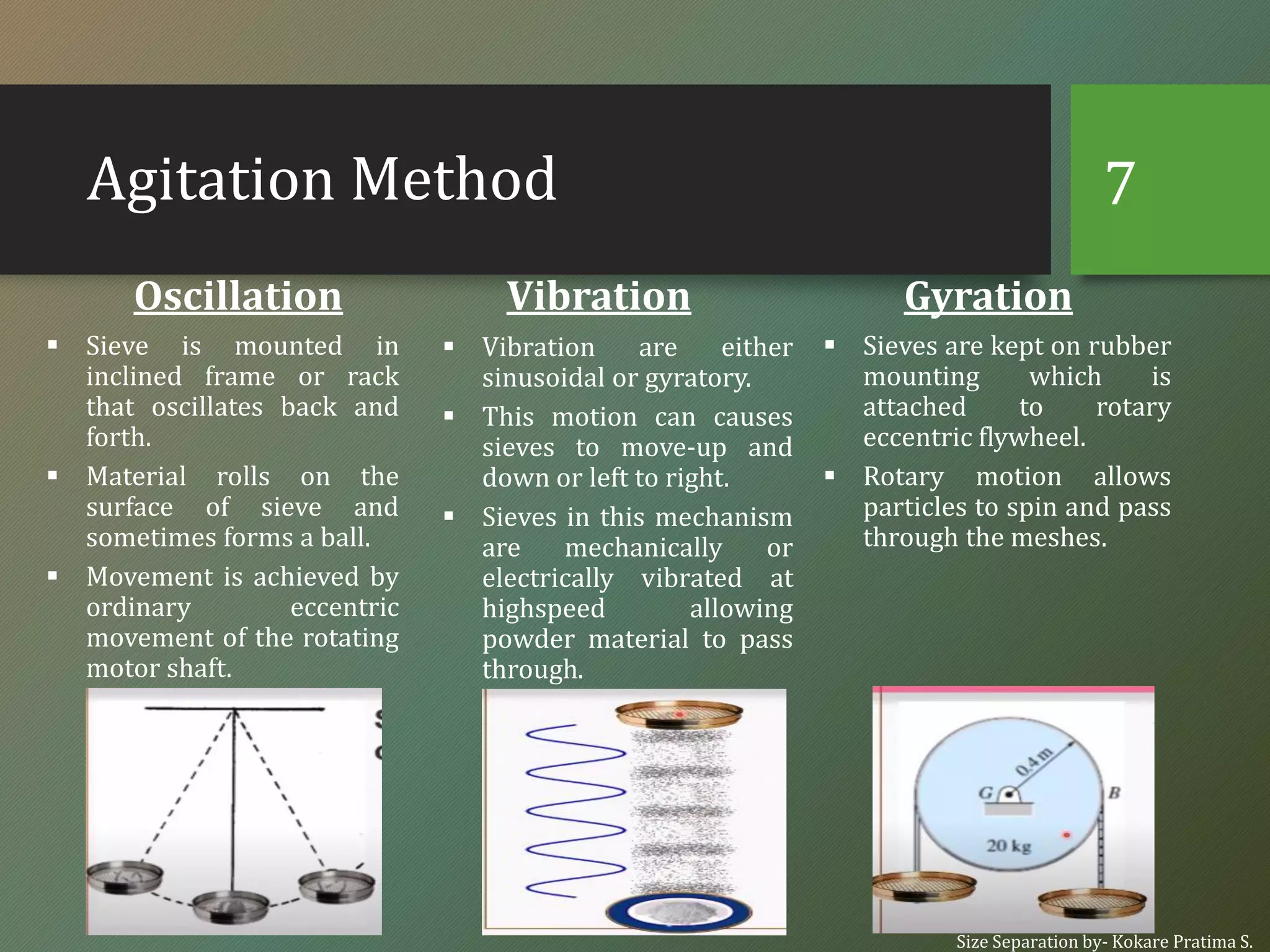

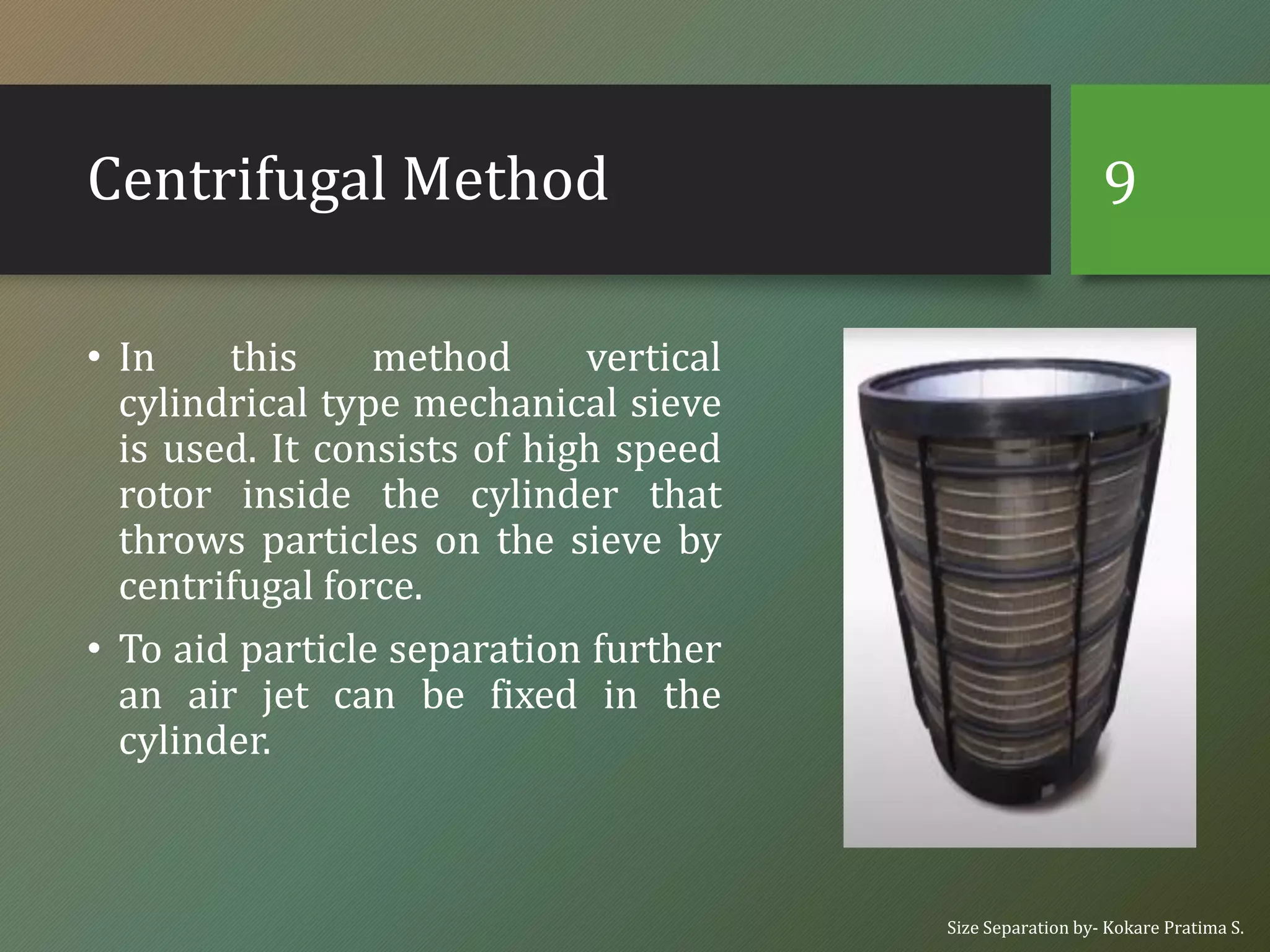

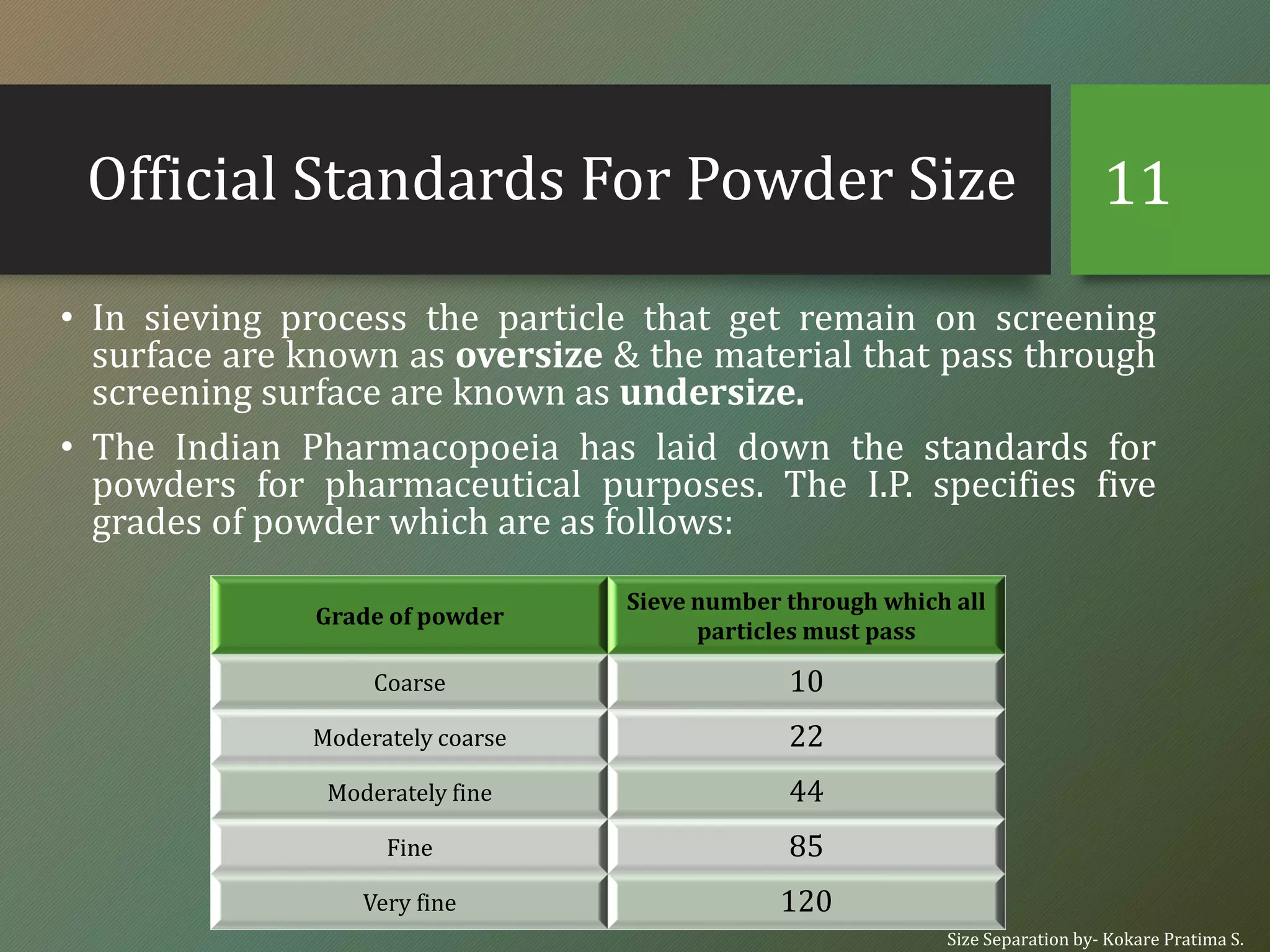

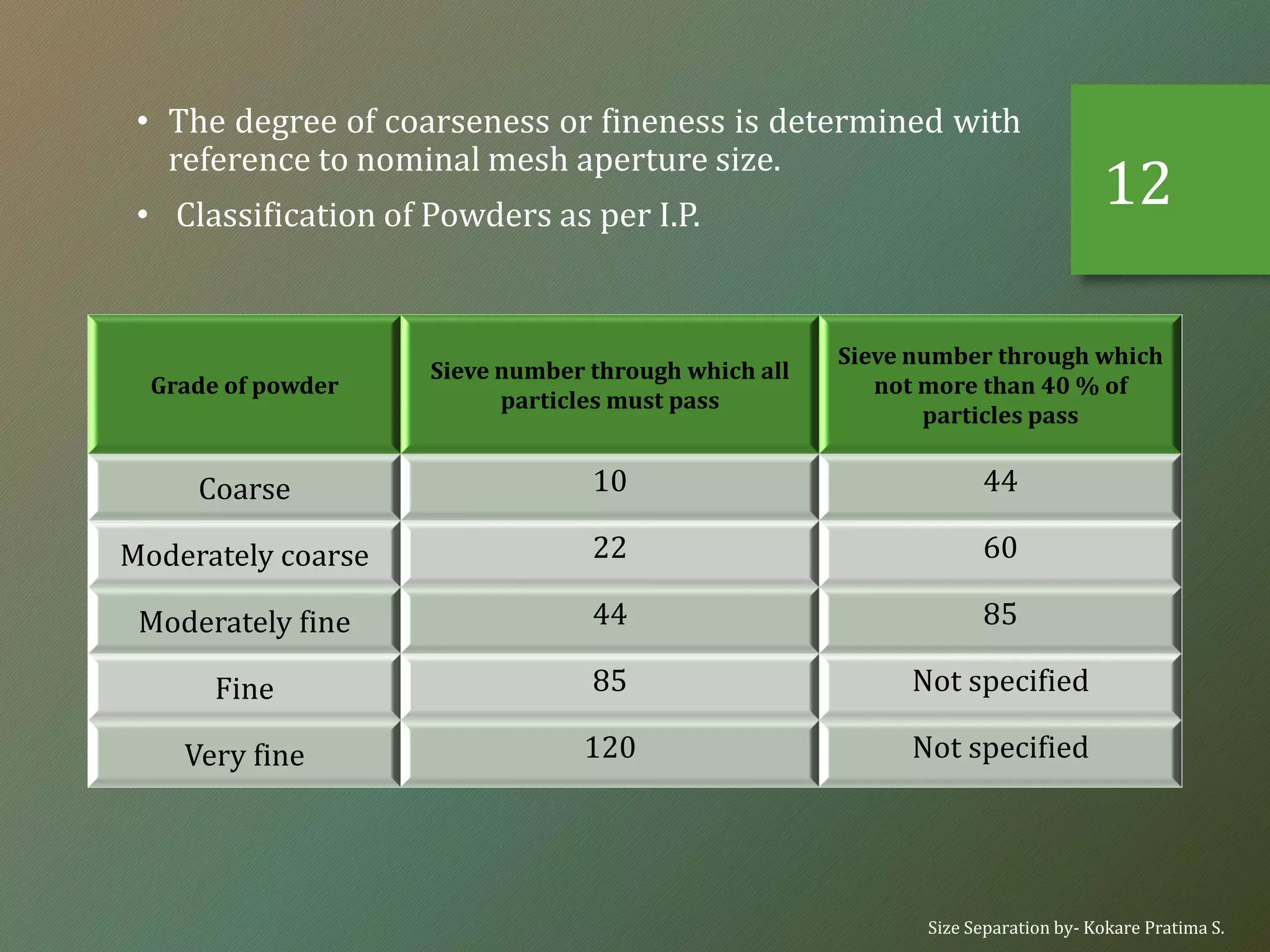

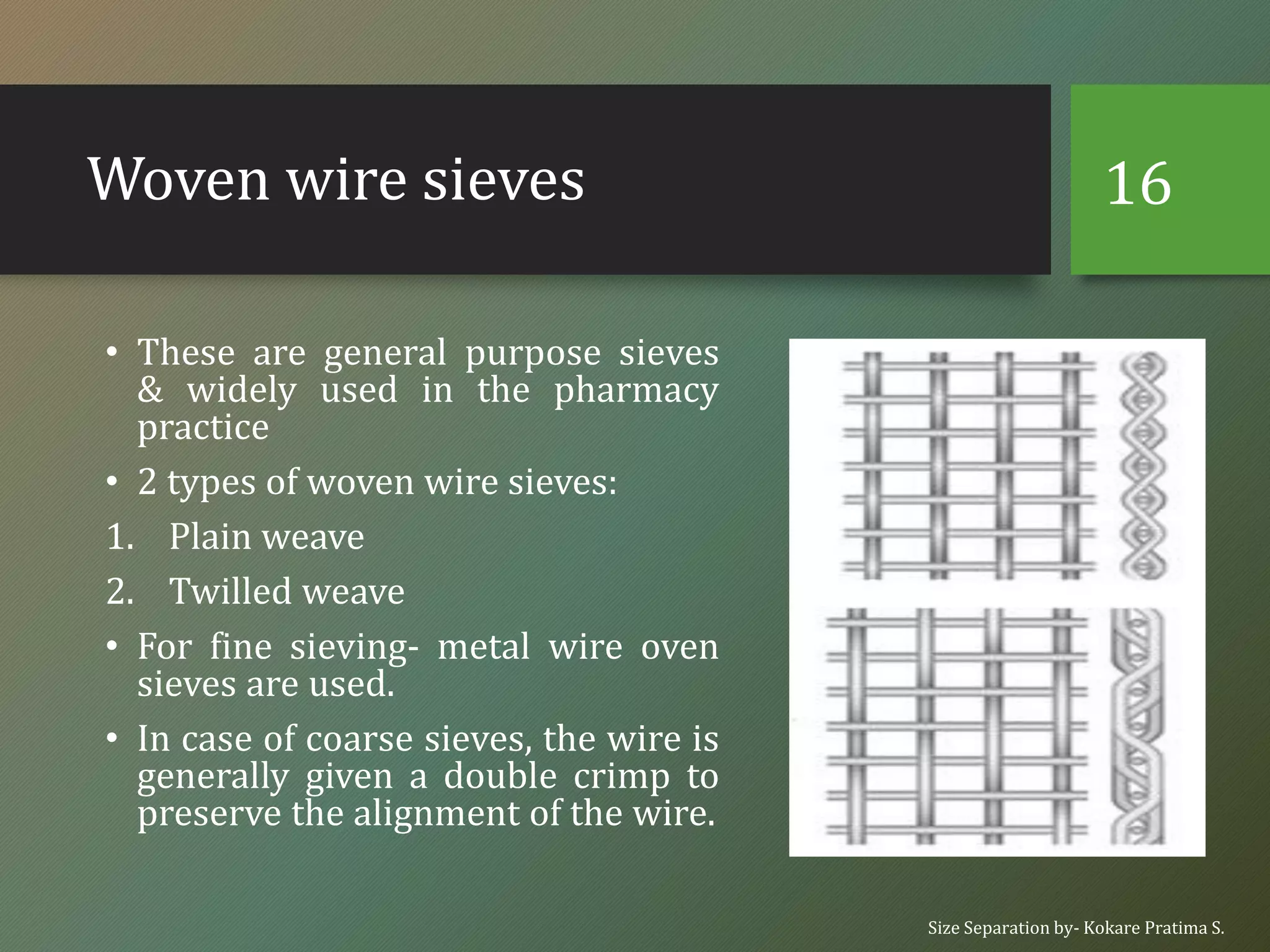

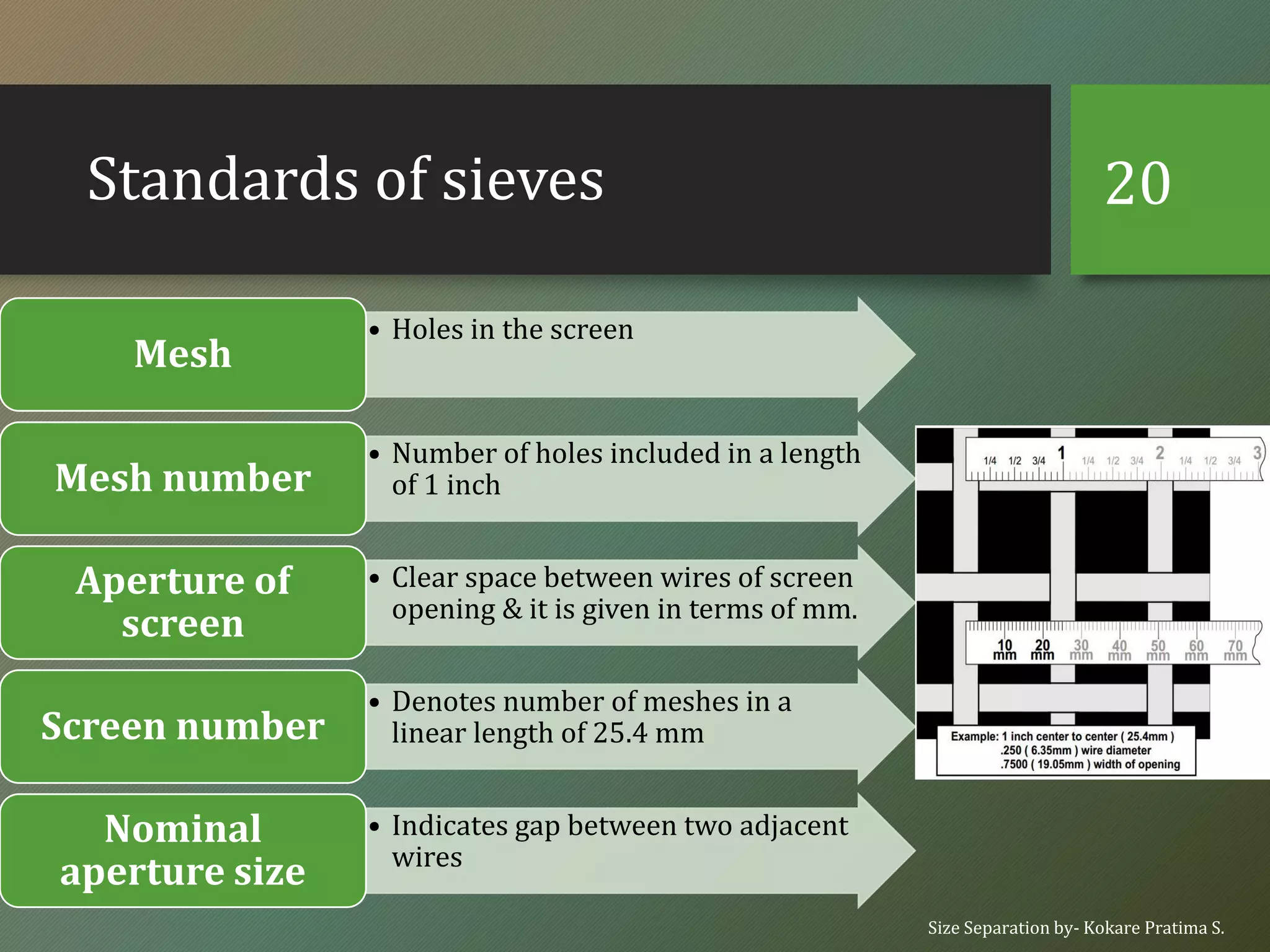

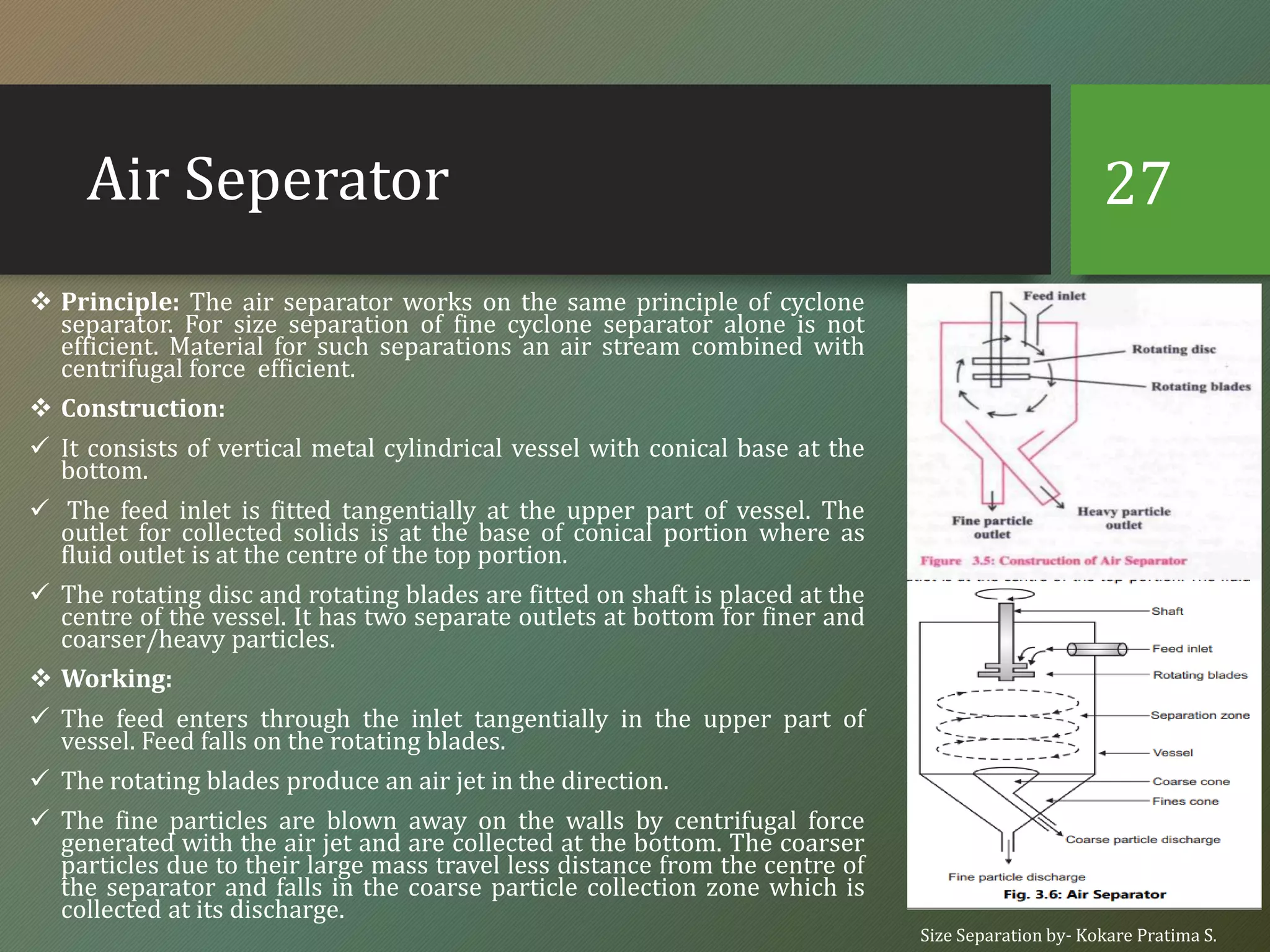

This document discusses size separation techniques that are used in the pharmaceutical industry. It begins by outlining the objectives and applications of size separation. The main mechanisms of size separation are then described, including agitation, gravitational force, density differences, and electrostatic force. Common equipment used for size separation like sieve shakers, cyclone separators, air separators, bag filters, and elutriation tanks are also introduced. The document provides details on sieve standards, specifications, and types. It concludes by stating that sieving is the most widely used particle size separation technique in the pharmaceutical industry.