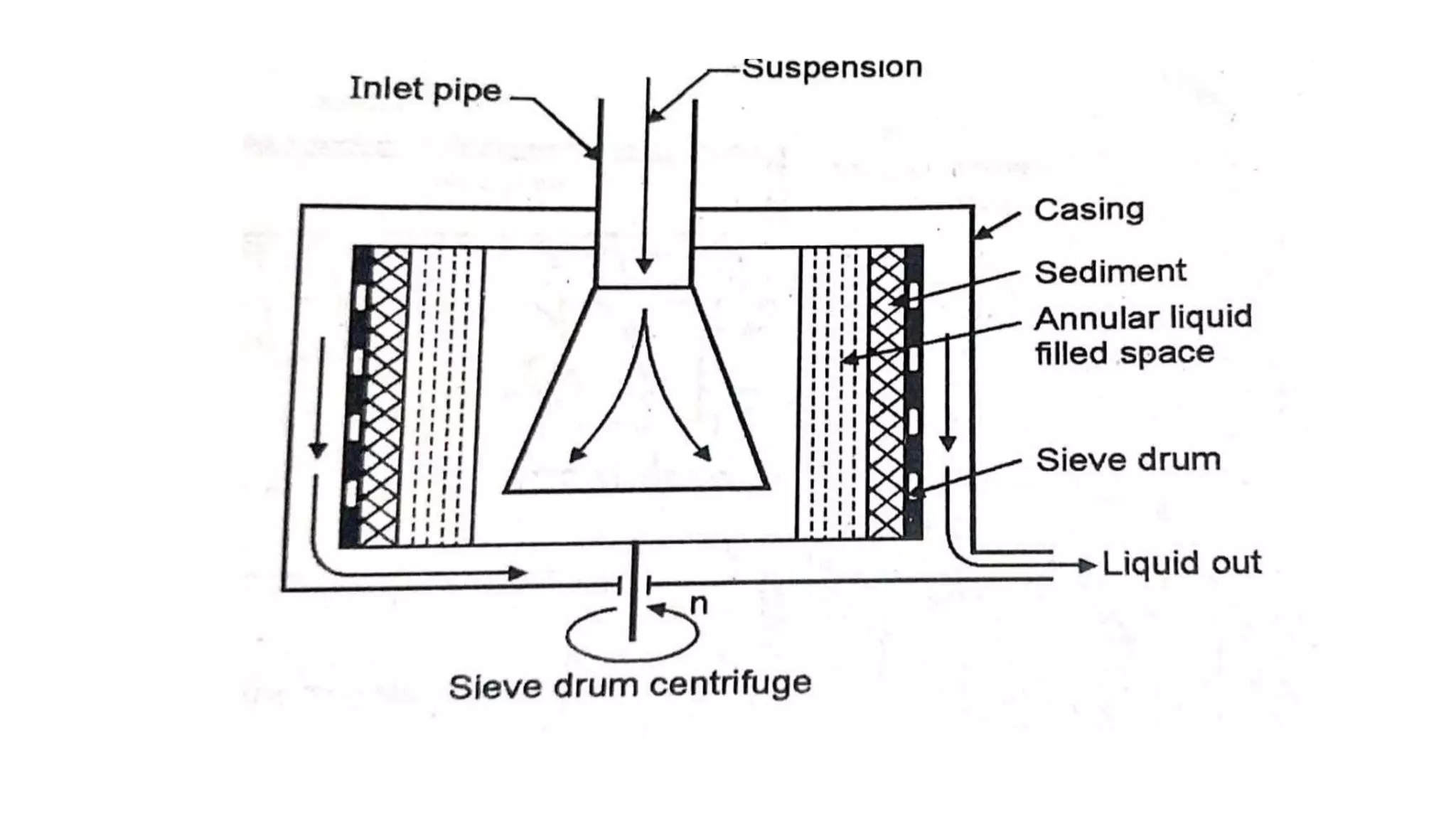

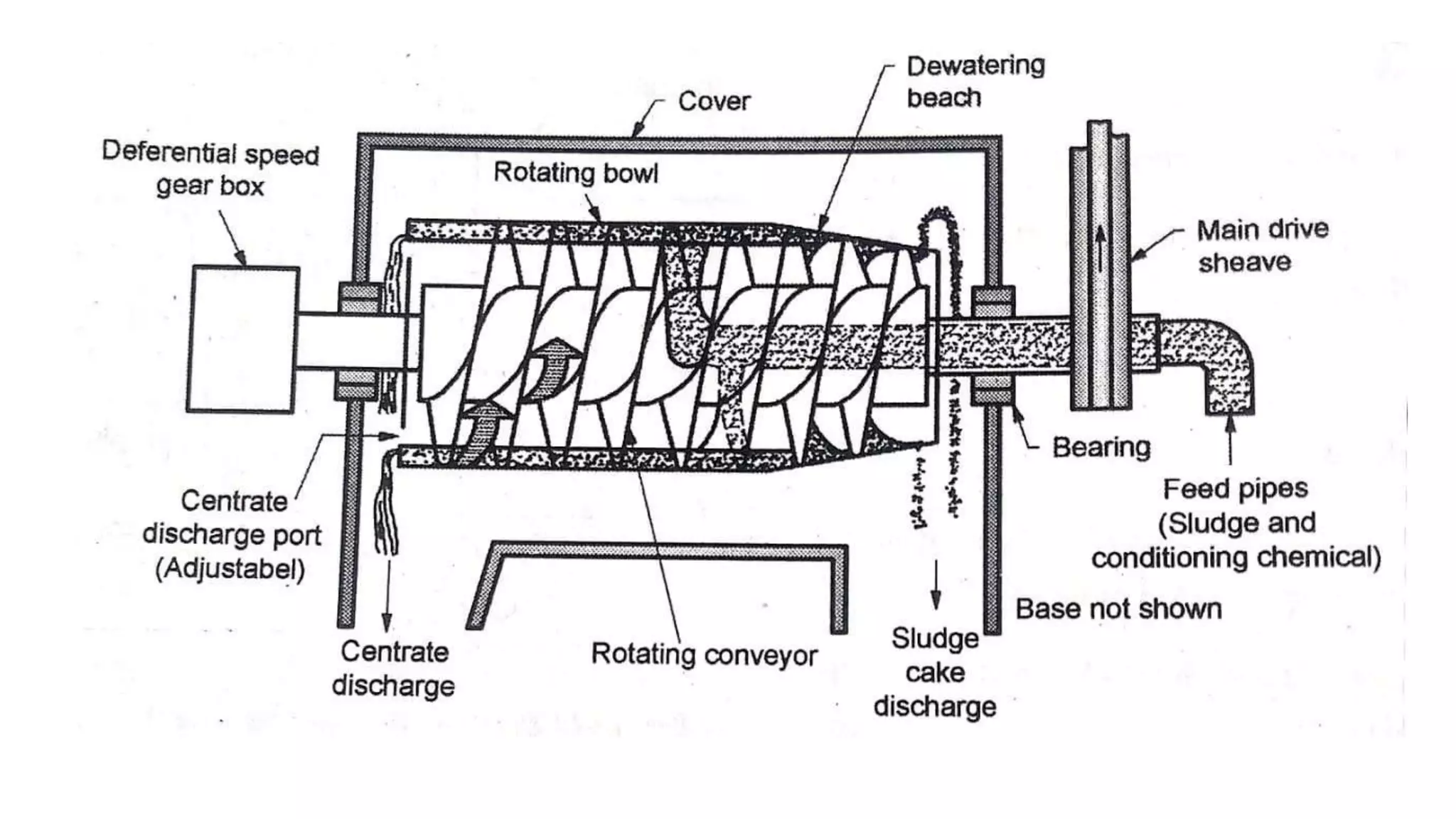

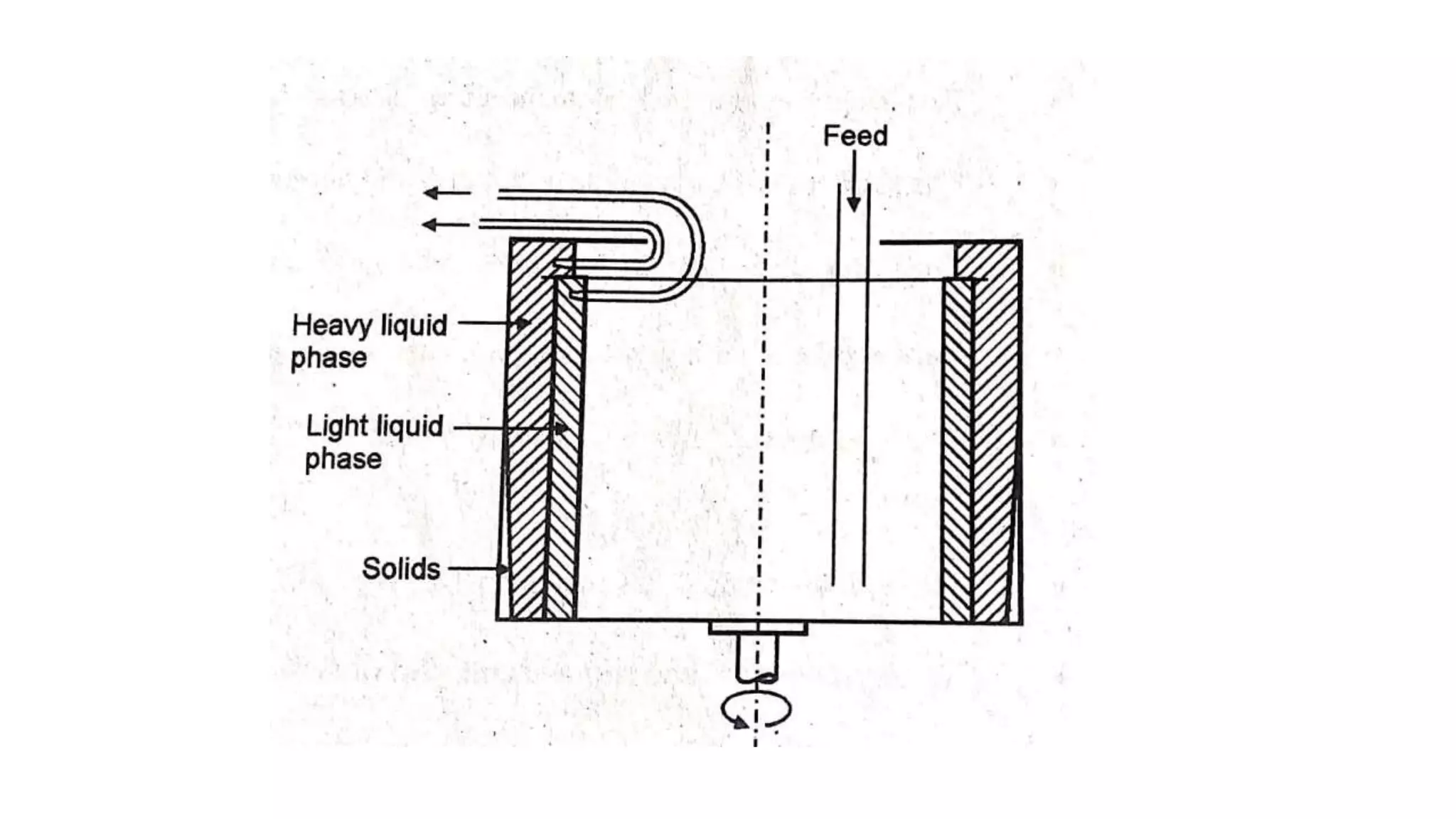

The document discusses centrifugation, outlining its objectives, principles, applications, and types of centrifuges including perforated and non-perforated basket centrifuges, semi-continuous centrifuges, and super centrifuges. It details the construction and working of each type, along with their advantages and disadvantages, highlighting their use in industries like bulk drug production and biological product evaluation. Overall, centrifugation is described as an essential technique for phase separation based on particle characteristics.