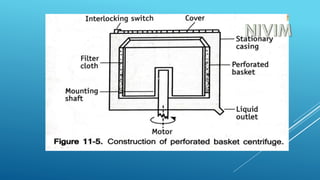

This document provides information about various filtration and centrifugation techniques used in pharmaceutical engineering. It discusses the principles, applications, and mechanisms of filtration including plate and frame filters, filter leaves, rotary drum filters, meta filters, cartridge filters, and membrane filters. It also covers the principles, objectives, and applications of centrifugation. Specific devices discussed include perforated basket centrifuges, non-perforated basket centrifuges, semi-continuous centrifuges, and super centrifuges. Theories related to filtration rate and factors influencing filtration are also summarized.