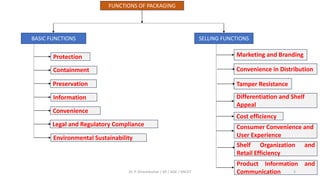

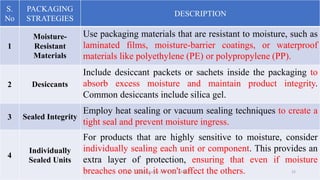

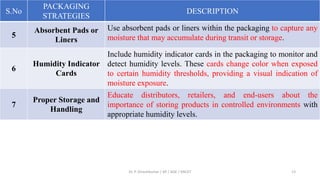

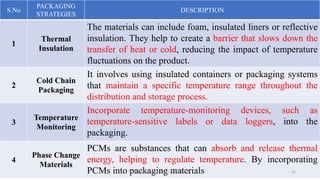

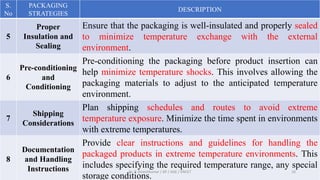

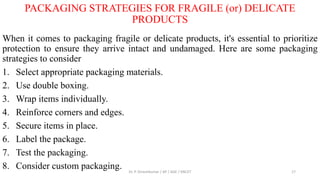

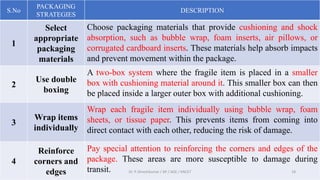

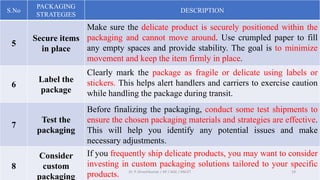

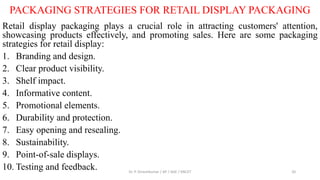

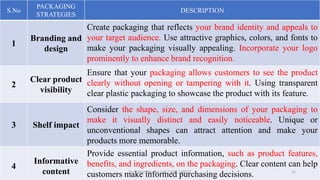

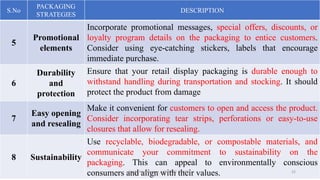

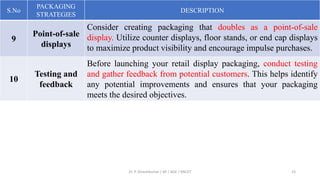

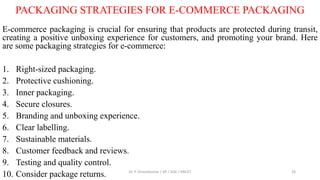

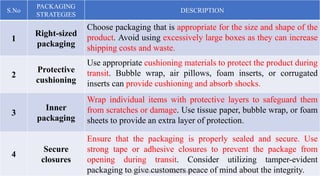

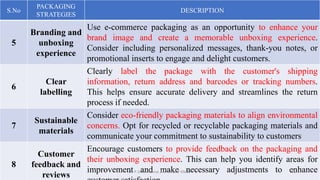

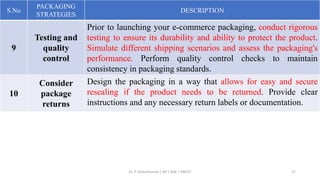

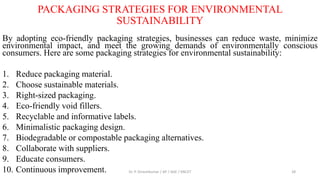

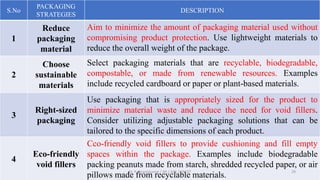

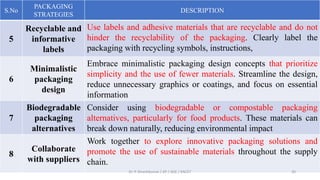

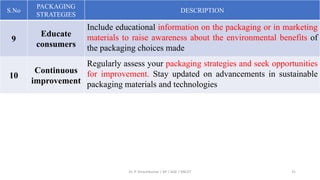

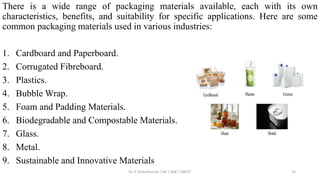

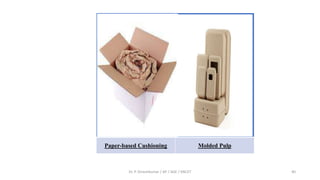

The document is a PowerPoint presentation about packaging materials and their functions. It discusses several key functions of packaging materials including protection, containment, preservation, information, convenience, legal and regulatory compliance, and environmental sustainability. It also covers selling functions such as marketing and branding, convenience in distribution, tamper resistance, differentiation, and product information. The presentation provides examples of packaging strategies for different environments like high humidity, extreme temperatures, fragile products, retail display, e-commerce, and strategies focusing on environmental sustainability.