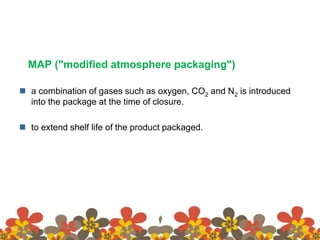

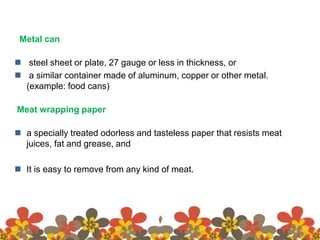

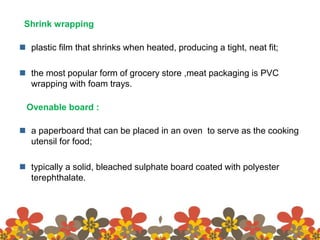

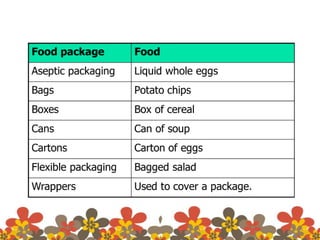

Modern packaging is expected to meet several requirements: it must protect contents from damage, not contain harmful chemicals, allow for easy identification, handling and disposal or recycling. It serves key functions like containment, information provision, preservation and protection. Common packaging terms include aseptic, breathing, retort and MAP packaging. Popular materials are metals, glass, paper, plastics and laminates. Each material has advantages - metals can preserve contents for long periods, glass allows visibility, paper is versatile, plastics are lightweight and rigid, and laminates combine strengths of different materials.