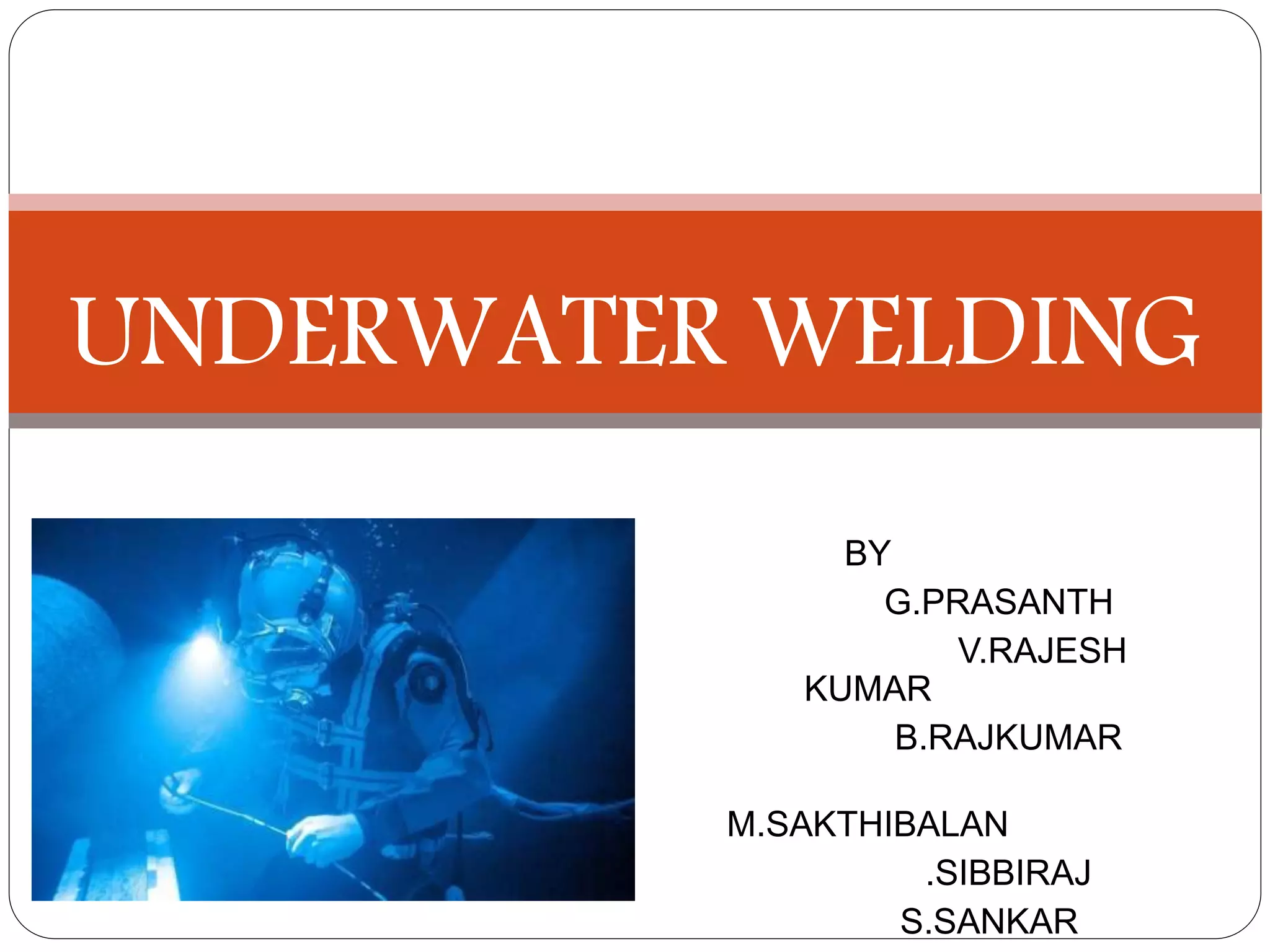

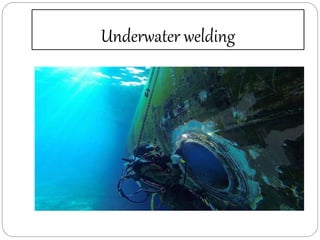

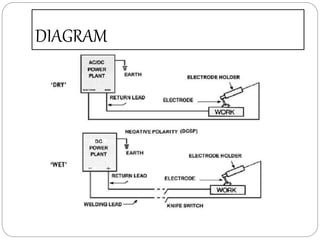

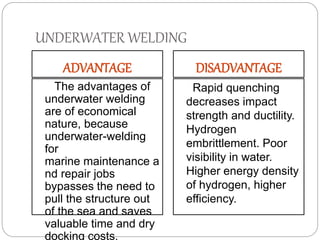

Underwater welding was invented in 1932 by Russian metallurgist Konstantin Khrenov. There are two main types of underwater welding: wet welding, which exposes the diver directly to water, and dry welding, which takes place inside a pressurized chamber. Underwater welding has economic advantages as it avoids the need to remove structures from water for repairs, but it also has disadvantages like reduced material strength and visibility issues. Underwater welding is used for applications like underwater pipelines, offshore oil rigs, ships, and other structures.