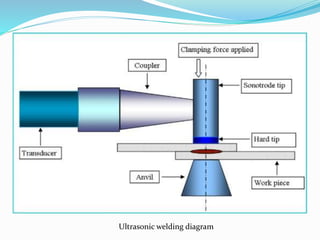

Ultrasonic welding uses high frequency sound waves to melt and bond materials like plastics and thin metals. It is a fast, non-contaminating technique that requires no consumables and minimizes heat affected zones and surface deformation. Ultrasonic waves are transmitted through parts held under pressure to generate localized heat through friction, welding the materials together in under 3 seconds with or without external heat. It can weld a variety of materials like plastics, metals, and glass and is used in industries like electronics, automotive, medical, and more.