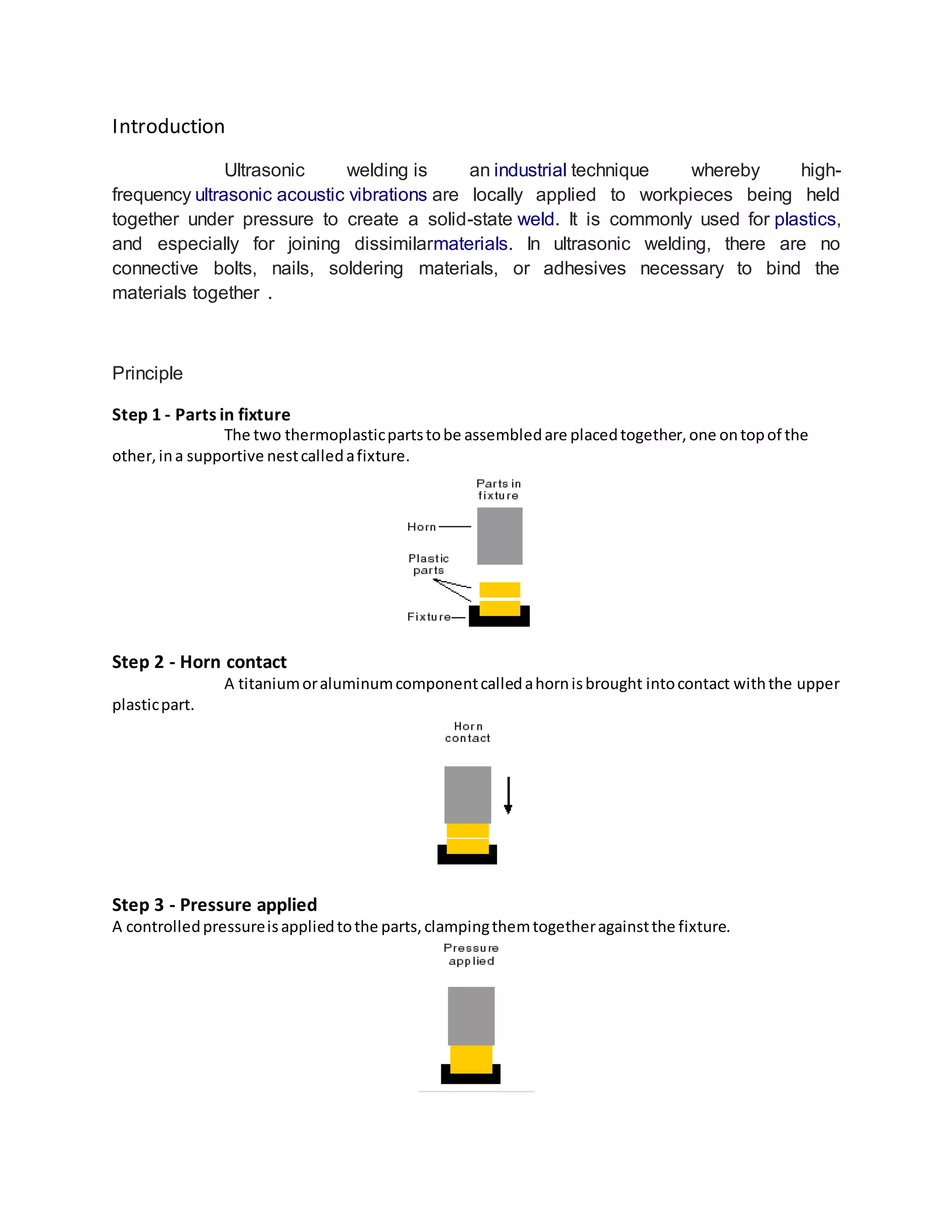

Ultrasonic welding is a technique that uses high-frequency sound vibrations to fuse together thermoplastic parts without fasteners, adhesives, or solvents. The process involves placing parts in a fixture, applying vibrational energy and pressure with a horn at the joint interface to generate heat through friction and melt the plastics. The parts are held together under continued pressure as the melted plastics cool and solidify, forming a clean, strong bond. No consumables are needed and the process is fast, efficient, and repeatable for plastic assembly.