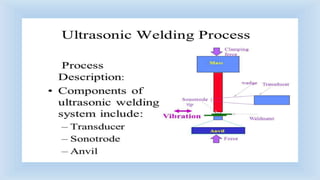

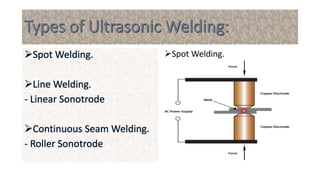

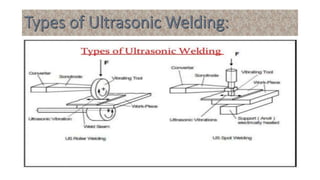

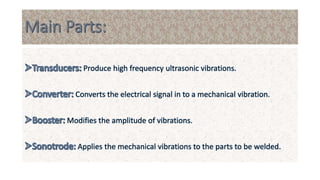

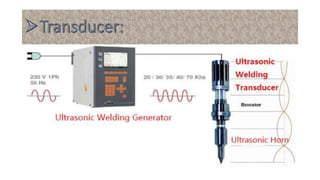

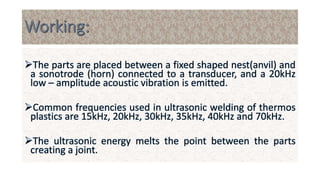

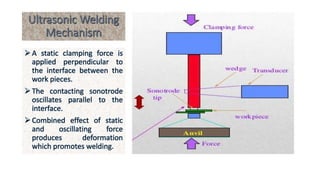

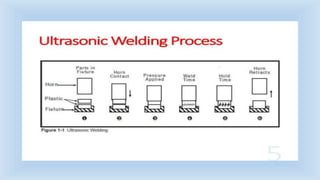

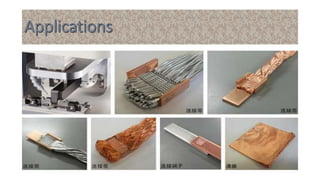

Ultrasonic welding uses high frequency ultrasonic vibrations to generate frictional heat and join materials under pressure. The vibrations are generated between 15-60 kHz by a transducer and transmitted to the parts through a sonotrode. Welding times are typically less than 3 seconds. Dissimilar materials and thin materials can be welded with minimal surface deformation and heat affected zones.