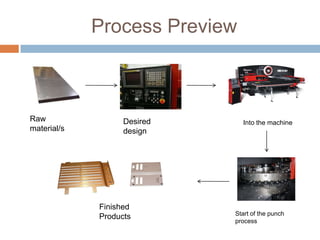

Turret punching is a CNC process that uses a turret punch machine to punch holes in sheet metal or plastic materials according to a programmed design. The material is clamped into the machine table which then moves it to the correct X/Y location for the turret-selected punch to create the desired hole shape. Turret punching is a cold working process that produces shapes in sheet metal through selective material removal. It is a fast and accurate process for making multiple holes in metal sheets.