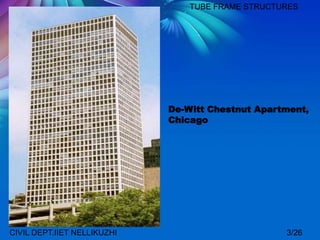

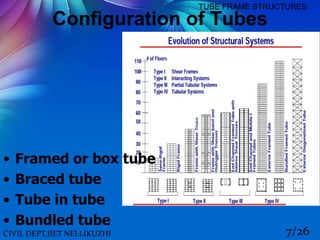

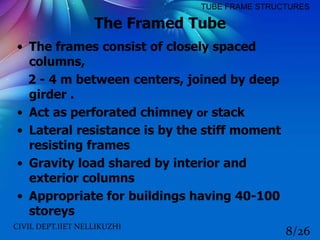

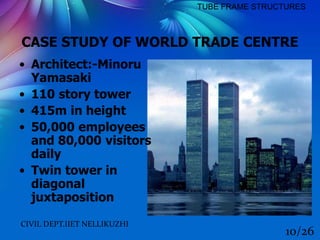

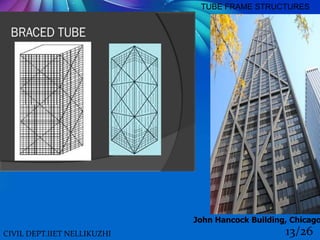

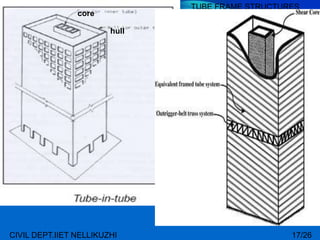

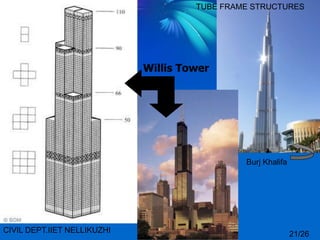

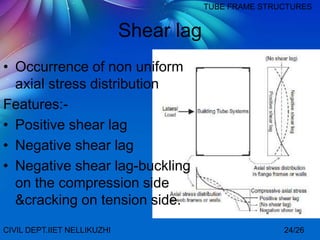

The document discusses tube frame structures for tall buildings. Tube frame structures were introduced by Fazlur Khan and involve a hollow cantilever tube perpendicular to the ground. They allow for buildings over 40 stories tall with configurations including framed tubes, braced tubes, tube-in-tube, and bundled tubes. Tube frame structures provide benefits like increased structural rigidity and regular column placement but also have disadvantages like reduced window size and occurrence of shear lag effects.

![References

1. Er. Nahant Rana,et.al.” Structural Forms Systems for Tall Building

Structures,SSRJ”, International Journal Of Civil Engineering (SSRG IJCE),

September 2014volume issued4

2. Hardin J. Patel,et,al. “Braced Tube Structural System: A review”

International Journal of Scientific & Engineering Research, December-2015, ,

Volume 6, Issue 12.

3. R. Mahjoub,et,al, “Simple Analysis of Tube Frame System of Tall Building by

Using Deformation Functions”. Australian Journal of Basic and Applied

Sciences, February 2011. [324-332]

4. Reza Mahjoub,et.al“Analysis of Tube Frame System of Tall Building by

Using of Deformation Functions”. Australian Journal of Basic and Applied

Sciences, 5(8): 1475-1482, 2011.

5. Sharadrao Patil,et.al, “Shear Lag in Tube Structures”. IJISET - International

Journal of Innovative Science, Engineering & Technology, March (2015), Vol.

2 Issue 3,

CIVIL DEPT.IIET NELLIKUZHI 26/26

TUBE FRAME STRUCTURES](https://image.slidesharecdn.com/zafppt1-161104150607/85/Tube-Frame-Structures-An-overview-28-320.jpg)