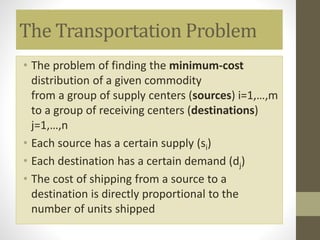

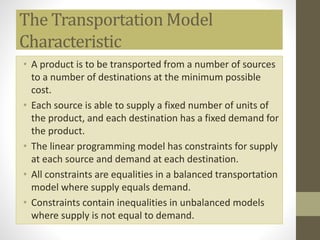

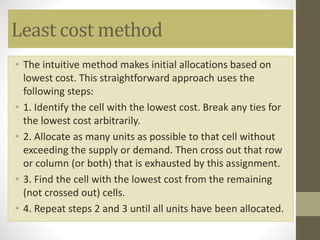

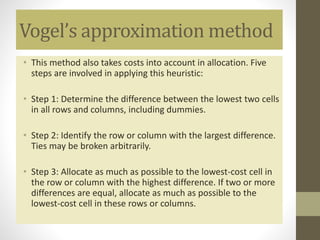

The transportation model aims to minimize shipping costs by finding the optimal distribution of goods from multiple sources to multiple destinations while satisfying supply and demand constraints. It encompasses both balanced and unbalanced transportation problems, with specialized methods such as the northwest corner rule and Vogel’s approximation method employed for obtaining initial and optimal solutions. The model is essential in various applications including cost minimization in logistics and production scheduling.