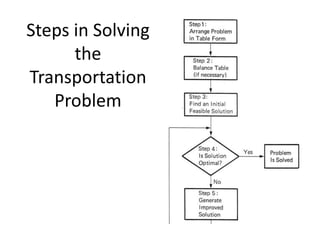

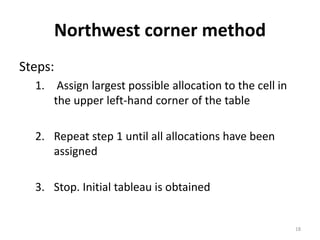

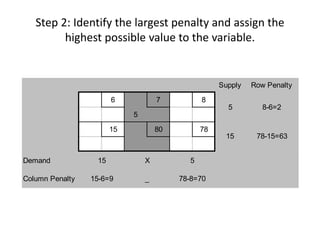

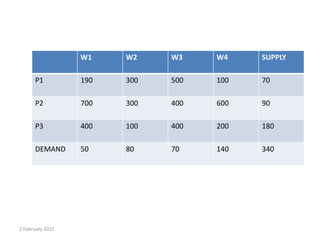

This document discusses transportation techniques and methods for solving transportation problems. It defines a transportation problem as aiming to find the best way to fulfill demand at multiple destinations using supply from multiple origins. It outlines the key components of a transportation model including origins, capacities, destinations, demands, and shipping costs. Three common solution methods are described - the minimum cost method, northwest corner method, and Vogel's approximation method - along with examples of each step. The document also lists some applications of transportation models like scheduling airlines and identifying facility locations.