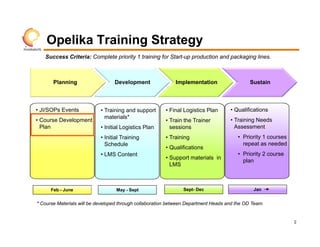

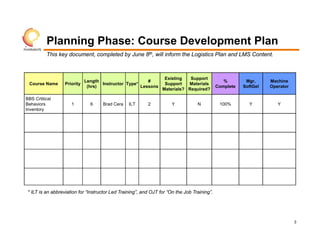

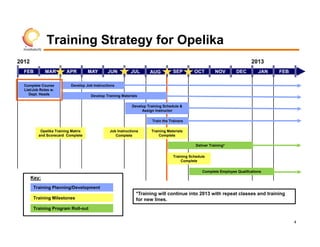

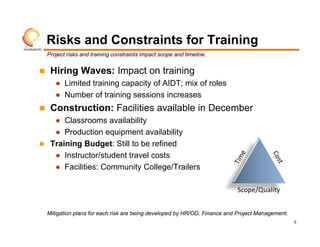

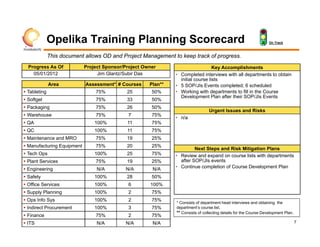

The document provides an overview of the training strategy and planning for the Opelika site. It outlines the key phases of planning, development, implementation and sustainment of training. It details the course development plan, risks around construction timelines and hiring waves, and a scorecard to track progress. The goal is to complete priority 1 training for startup production and packaging lines by the end of 2012.