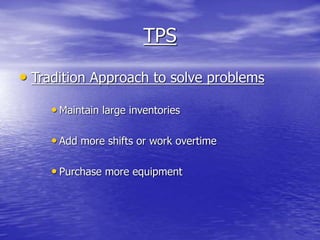

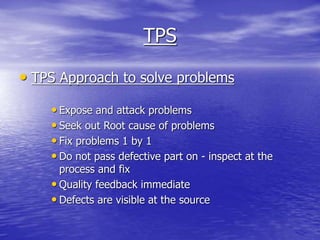

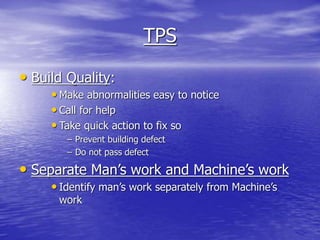

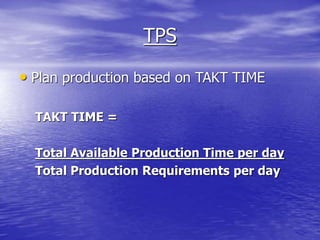

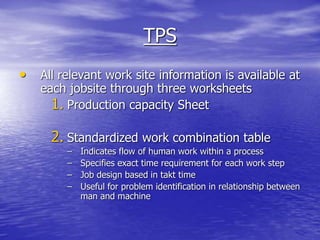

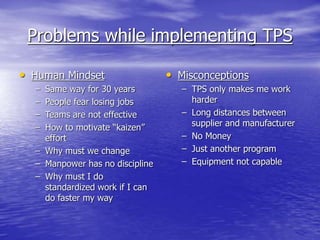

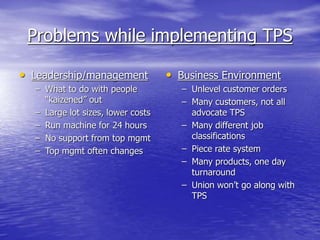

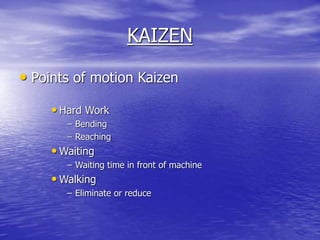

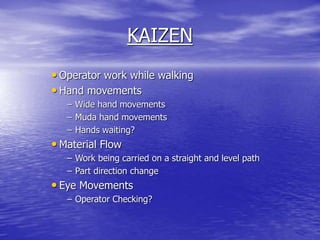

This document summarizes Toyota's Production System (TPS) philosophy and principles. TPS was developed based on Kiichiro Toyoda's philosophy to compete with large automakers through small volume production with low capital costs. Key principles of TPS include putting customers first, respecting people, continuous improvement (Kaizen), eliminating waste, building quality in from the start, and pacing production to match sales. TPS aims for the highest quality, lowest cost and shortest lead times through stability, standardized work, visual management, and respect for people. Challenges to implementing TPS include changing mindsets, leadership support, and business environment factors.