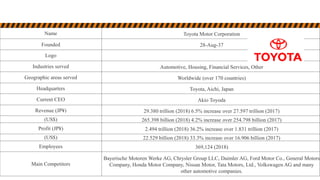

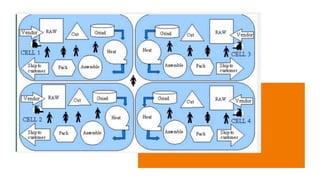

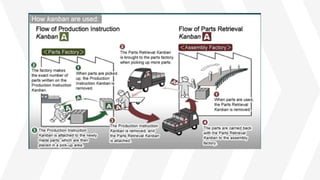

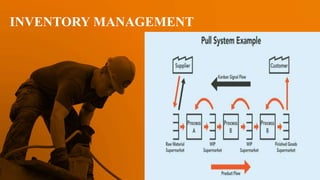

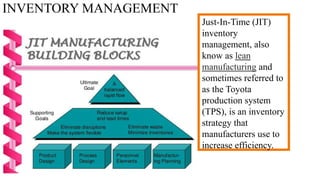

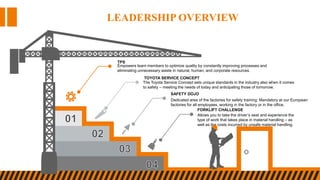

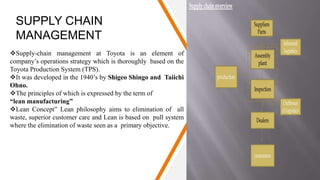

Toyota is a large Japanese automaker founded in 1937. It has global operations in over 170 countries and annual revenue of over $265 billion. Toyota employs over 369,000 people worldwide and is headquartered in Toyota City, Japan. The company pioneered the Toyota Production System, also known as lean manufacturing, which emphasizes eliminating waste. Toyota has a focus on just-in-time inventory management, continuous process improvement, and uses a pull-based production system. The document provides details on Toyota's operations management strategies, production layout, material handling, and inventory management approach.