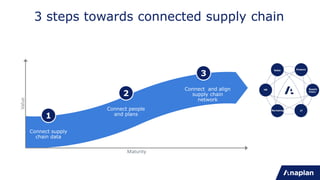

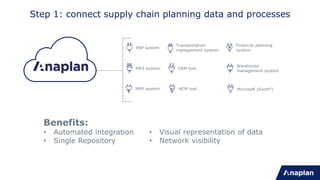

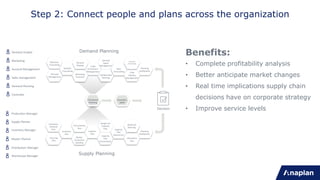

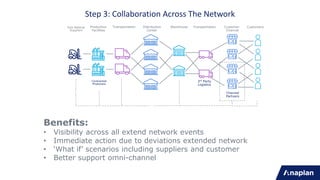

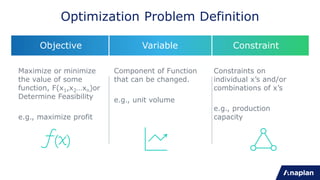

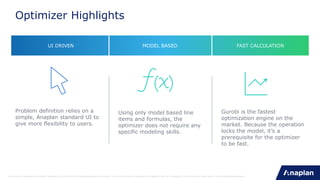

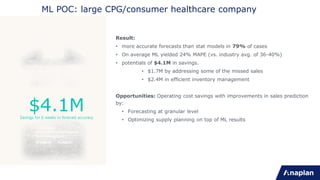

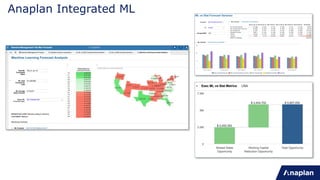

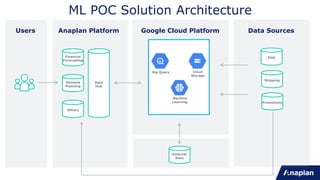

The document discusses the role of Anaplan in promoting connected supply chain planning through its technology and capabilities, emphasizing the need for overcoming organizational silos and enhancing data visibility. It highlights significant operational improvements and cost savings achieved by various companies through Anaplan's innovative solutions, including reductions in planning cycle times and improved forecast accuracy. The document also suggests that integrating machine learning with Anaplan can lead to better decision-making and substantial financial benefits.