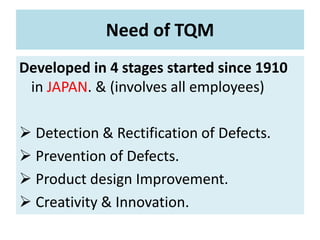

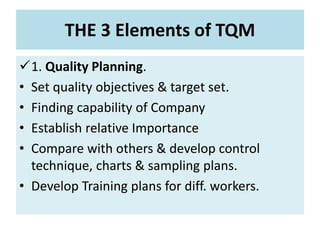

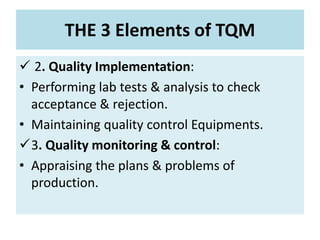

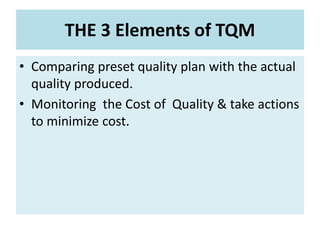

This document discusses Total Quality Management (TQM), which aims to continuously improve quality through cooperation between workers and innovation. It identifies W. Edwards Deming as the "Father of TQM" and outlines its three objectives as meeting changing customer requirements, continuous improvement, and employee involvement. The three elements of TQM are quality planning, implementation, and monitoring/control. Benefits include high quality products, customer satisfaction, and reduced costs. TQM is implemented through Deming's Plan-Do-Check-Act cycle, involving quality policies, improvement methods, training, operations, problem analysis, and prevention.