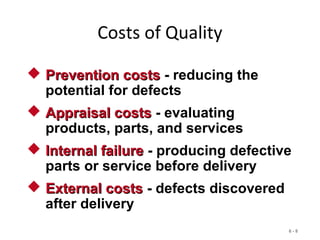

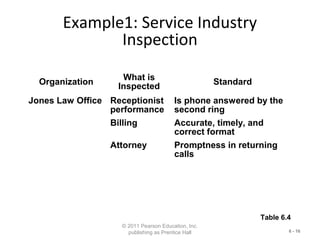

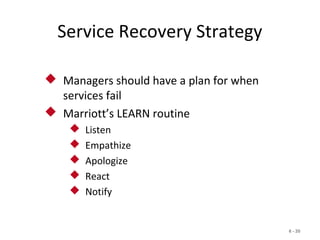

This document discusses strategies for quality assurance in hospital management. It covers three main objectives: 1) understanding the strategy to obtain quality and its costs, 2) understanding the seven concepts of total quality management, and 3) understanding service quality inspection and recovery. The key points are that quality assurance requires identifying customer needs, implementing quality principles and empowering employees, inspecting for quality at various stages, and having a service recovery strategy when failures occur. The document provides examples of quality inspections for service industries like law offices, hotels, and hospitals.