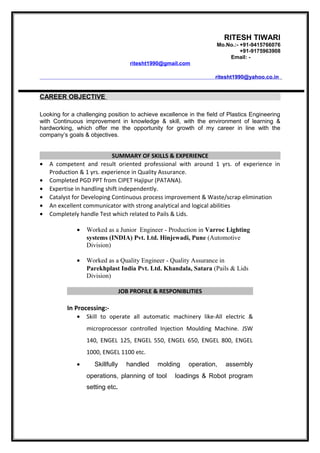

Ritesh Tiwari is seeking a challenging position in plastics engineering with opportunities for career growth and learning. He has over 2 years of experience in production and quality assurance. He holds a Post Graduate Diploma in Plastics Processing and Testing and has expertise operating various injection molding machines and handling quality control processes like testing, inspection, and reducing rejection rates. His skills include production planning, process improvement, and supervising production teams.