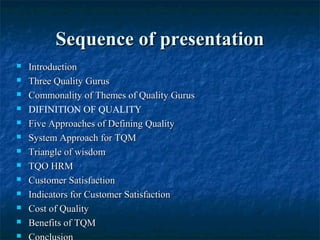

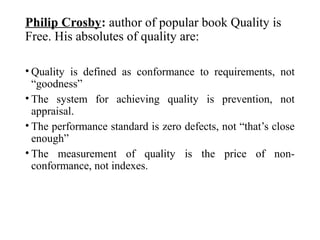

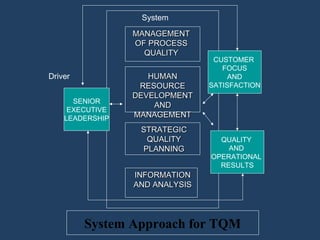

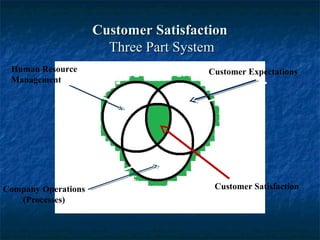

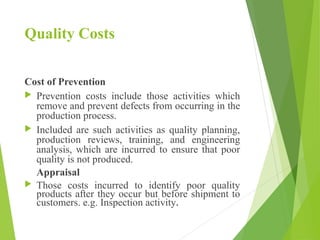

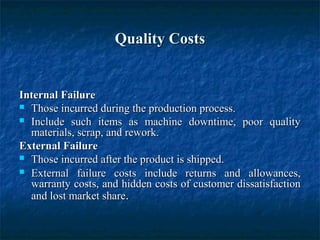

Total quality management (TQM) aims to integrate all processes to achieve continuous quality improvement and customer satisfaction. The three main quality gurus - Deming, Juran, and Crosby - emphasized that quality is defined by customer requirements and inspection alone cannot ensure quality. TQM requires organization-wide commitment and views quality costs as those incurred from non-conformance rather than quality activities. The goal of TQM is to reduce quality costs and increase customer loyalty through a system approach.