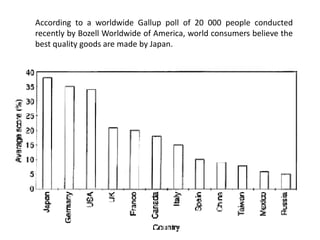

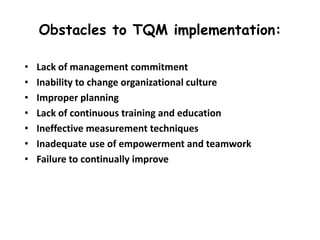

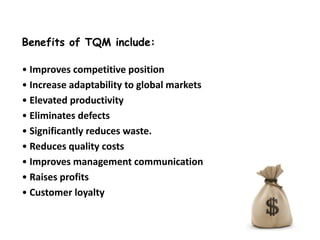

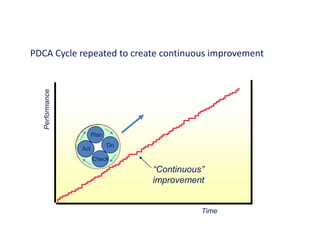

Total Quality Management (TQM) is a management approach that aims to continually improve processes by involving all employees and focusing on customer satisfaction. The document defines quality and its dimensions such as functionality, reliability, and aesthetics. It explains that TQM requires commitment from leadership to promote cultural change and remove barriers. The main pillars of TQM are customer satisfaction, management commitment, employee involvement, and continual improvement. Benefits include increased productivity, reduced costs, and improved profits. TQM uses a PDCA cycle of plan, do, check, act to drive continuous improvement over time.