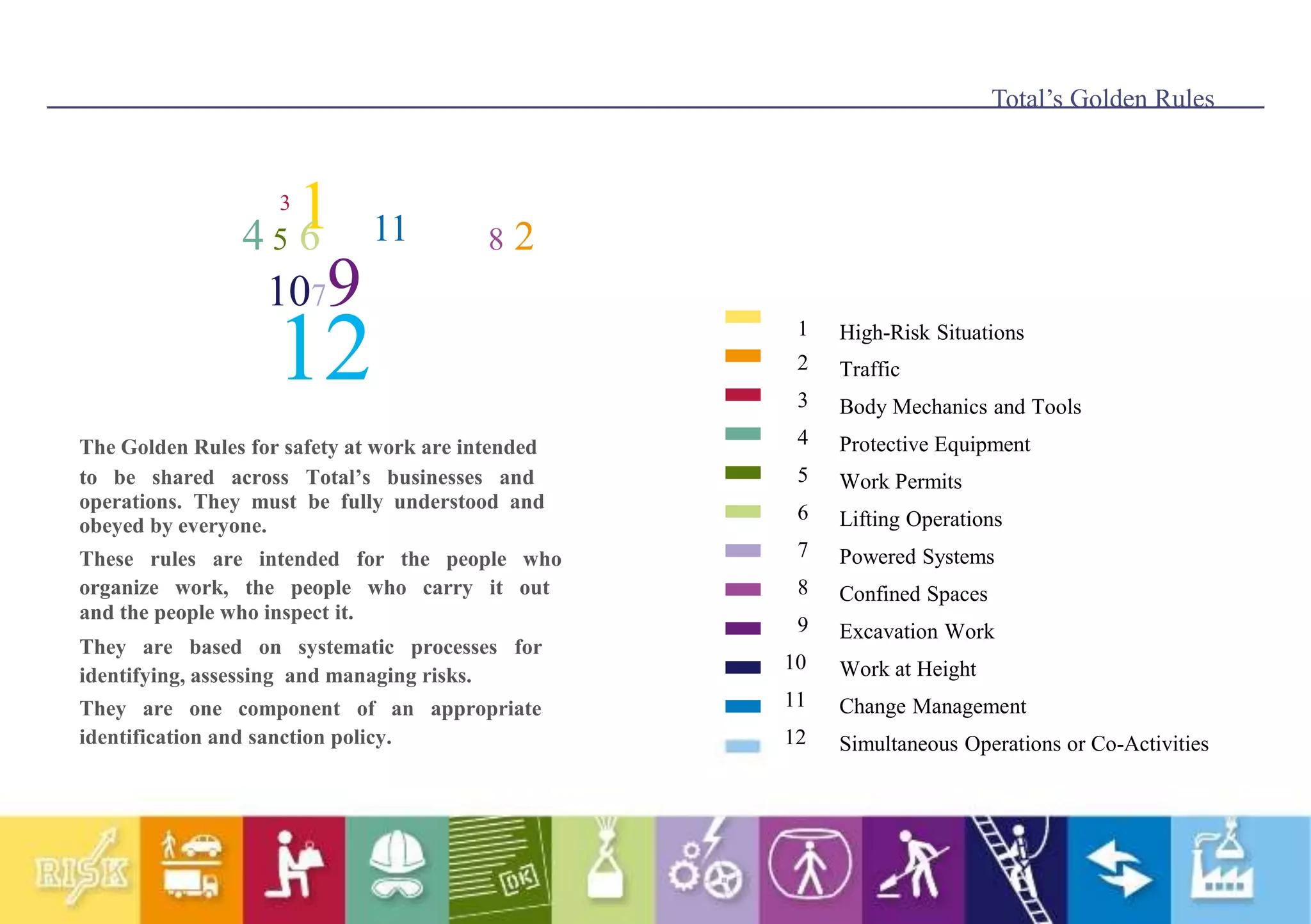

The document outlines Total S.A.'s Golden Rules for safety at work. It introduces the 12 Golden Rules, which cover high-risk situations, traffic, body mechanics, protective equipment, work permits, lifting operations, powered systems, confined spaces, excavation work, work at height, change management, and simultaneous operations. Compliance with the Golden Rules is required to prevent accidents across Total's operations. Failure to comply can result in disciplinary action.