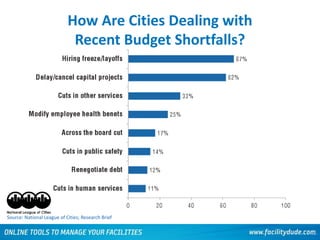

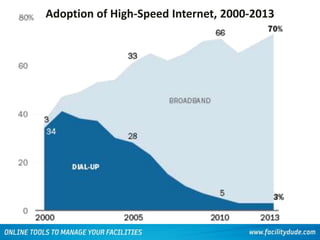

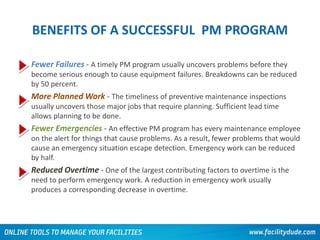

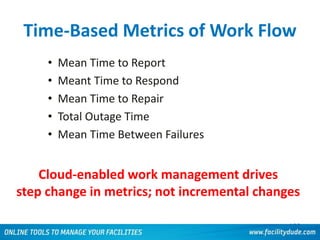

This document discusses how building operations can benefit from integrating building control technology and cloud-based management tools. It begins by outlining the current economic challenges facing facilities management, including aging infrastructure, limited capital budgets, and rising operational costs. It then examines how technology trends like cloud computing and connectivity are changing expectations. The rest of the document provides recommendations on how facilities can leverage existing building automation systems and computerized maintenance management software to improve operations, such as generating automated work orders from smart equipment, implementing condition-based preventative maintenance, and reducing energy and labor costs through automated facility scheduling. The overall message is that integrating building controls and cloud tools can help facilities maximize efficiency and return on investment despite economic constraints.