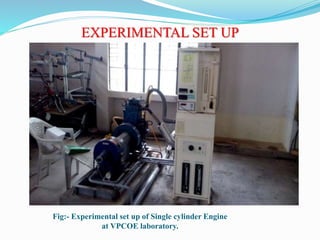

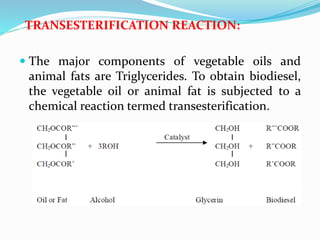

This project presentation summarizes research on using high speed trains. It discusses the primary problem with existing railways which is tight curves that create high centrifugal forces at high speeds. High speed lines aim to address this by having broader curves. The presentation was submitted by Mr. Garad Akshay Balaji for his mechanical engineering course. It explores using vegetable oils and biodiesel from sources like Jatropha and Undi in engines. The advantages and disadvantages of vegetable oils and biodiesel are summarized. The presentation discusses transesterification to reduce viscosity for use in engines and shows the experimental setup. It outlines the objectives to analyze parameters like power, fuel consumption and emissions from blends of the oils.

![To study tentative graphical analysis of

Jatropha biodiesel

Variation Of Brake Power With Specific Fuel

Consumption.

Variation Of Brake Power With Break thermal efficiency.[7.J.Narayana Reddy]](https://image.slidesharecdn.com/ccppresentation-200118083012/85/High-speed-Trains-Mechanical-Engineering-Paper-Presentation-BPP-Kalamb-16-320.jpg)

![Variation Of Brake Power With Specific Fuel Consumption [7.J.Narayana Reddy]](https://image.slidesharecdn.com/ccppresentation-200118083012/85/High-speed-Trains-Mechanical-Engineering-Paper-Presentation-BPP-Kalamb-17-320.jpg)

![Variation Of Brake Power With CO2 [7.J.Narayana Reddy]](https://image.slidesharecdn.com/ccppresentation-200118083012/85/High-speed-Trains-Mechanical-Engineering-Paper-Presentation-BPP-Kalamb-18-320.jpg)