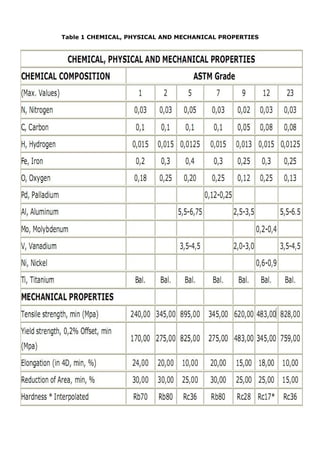

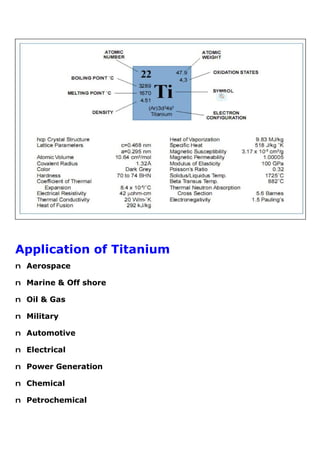

Baoji Mingkun Nonferrous Metal Co.,Ltd is a Chinese manufacturer of titanium, tantalum, zirconium, and other exotic metals. They have over 30 years of experience in machining and welding metals. The company produces a wide range of titanium products including bars, rods, sheets, plates, wires, tubes, pipes, forgings, and machined components. They have various equipment for processing metals including drilling machines, milling machines, lathes, and presses. Titanium grades range from pure titanium to high strength alloys, with applications in aerospace, marine, oil and gas, military, automotive, and other industries.