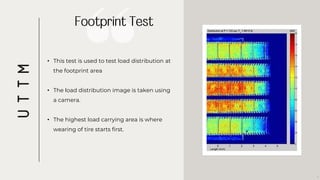

This document discusses various types of tire testing that manufacturers use to ensure tire quality and safety compliance. It describes indoor and outdoor tire testing as well as specific tests like bead compression, carcass strength, rolling resistance, wet/dry grip, noise, and stopping distance. Several tire testing machines are introduced that can perform stiffness, footprint, and electrical resistance tests or subject tires to lateral, radial, torsional, and tangential forces at high speeds. Load distribution and wear patterns are also evaluated.