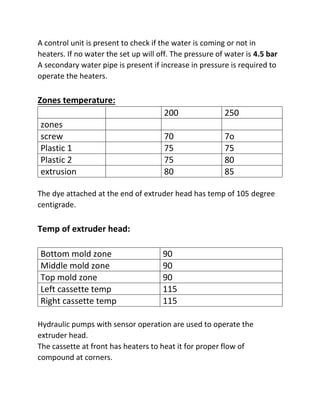

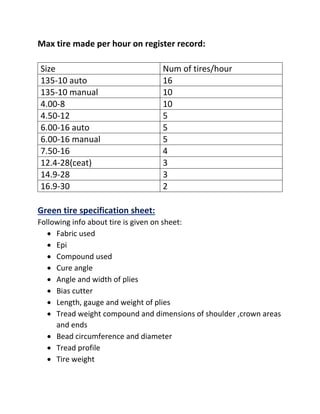

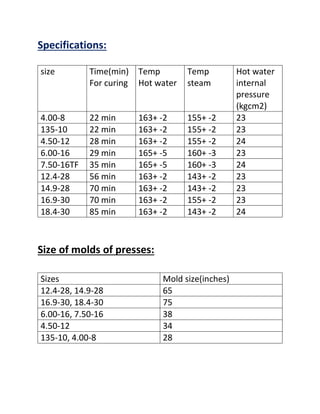

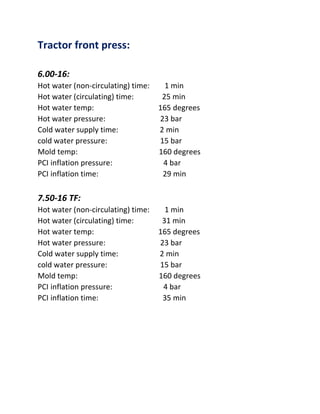

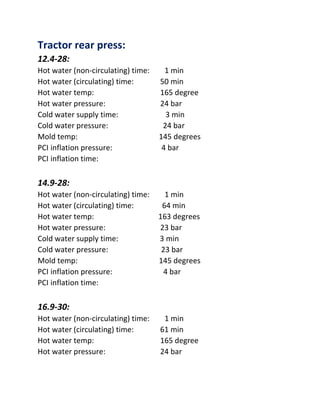

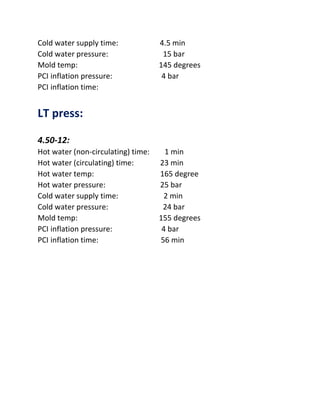

The document provides details about the technical aspects of tire production at a tire department. It describes the different types of tires produced including agriculture, rickshaw, tractor, and light truck tires. It then outlines the key components and processes involved in tire building, such as the sizes and specifications of extruders, bead wire machines, tire building machines, and other production equipment. Production details like tire component materials, sizes, specifications, capacities and processes are included for each stage of tire manufacturing.