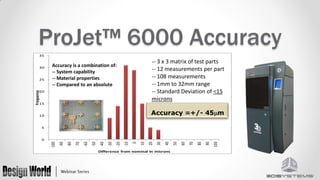

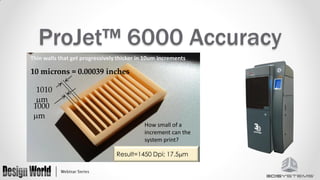

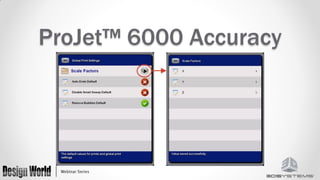

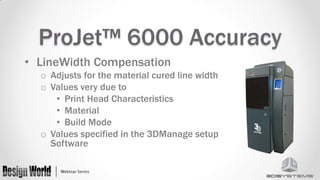

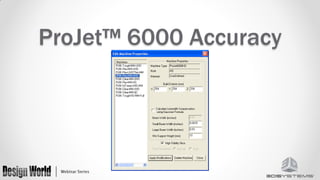

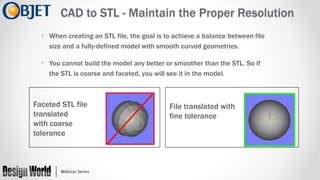

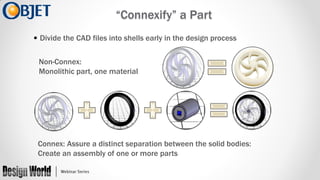

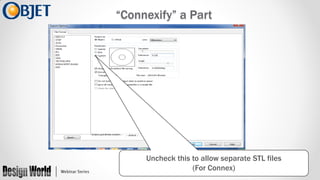

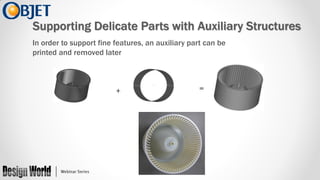

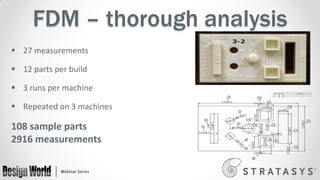

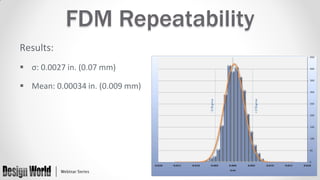

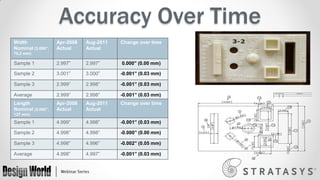

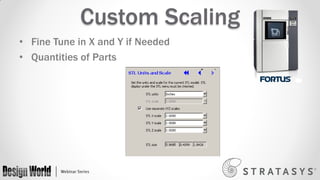

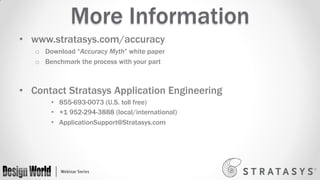

The document outlines a webinar on 3D printing accuracy, highlighting the features and capabilities of the Projet 6000, including digital self-calibration and material shrinkage compensation. It emphasizes the importance of maintaining proper resolution when creating STL files and strategic design practices for producing accurate parts using various materials. Additionally, the document provides insights on routine maintenance for FDM systems to ensure stability and repeatability in printing.