The document discusses thermoelectric cooling, which uses the Peltier effect to create a heat pump-like cooling system without moving parts. It operates by passing a current through two dissimilar conductors joined at two points maintained at different temperatures. When current is applied, heat is absorbed at one junction and expelled at the other, allowing one side to be cooled. Thermoelectric coolers use semiconductors like bismuth telluride in a series of p-n junctions to transfer heat from one side to the other in response to an applied current, providing solid-state cooling without liquids or gases.

![scientists began studying some of the earlier thermoelectric work in an effort to construct

power generators for use at remote locations throughout the country. This Russian interest in

thermoelectricity eventually caught the attention of the rest of the world and inspired the

development of practical thermoelectric modules. Today‟s thermoelectric refrigerators make

use of modern semi-conductor technology whereby doped semi-conductor material takes the

place of dissimilar metals used in early thermoelectric experiments. [Ref.1]

In 1821, Thomas Seebeck discovered that a continuously flowing current is created when two

wires of different materials are joined together and heated at one end.This idea is known as the

Seebeck Effect. The Seebeck effect has two main applications including temperature

measurement and power generation. Thirteen years later Jean Charles Athanase reversed the

flow of electrons in Seebeck.s circuit to create refrigeration. This effect is known as the Peltier

Effect. This idea forms the basis for the Thermoelectric refrigerator.Scottish scientist

WilliamThomson (later Lord Kelvin) discovered in 1854 that if a temperature difference exists

between any two points of a current carrying conductor, heat is either evolved or absorbed

depending upon the material.6 If such a circuit absorbs heat, thenheat may be evolved if the

direction of the current or of the temperature gradient is reversed[1]. The Peltier effect is a

temperature difference created by applying a voltage between two electrodes connected to a

sample of semiconductor material. This phenomenon can be useful when it is necessary to

transfer heat from one medium to another on a small scale. The Peltier effect is one of three

types of thermoelectric effect; the other two are theSeebeck effect and the Thomson effect. In

a Peltier-effect device, the electrodes are typically made of a metal with excellent electrical

conductivity. The semiconductor material between the electrodes creates two junctions

between dissimilar materials, which, in turn, creates a pair of thermocouple voltage is applied

to the electrodes to force electrical current through the semiconductor, thermal energy flows in

the direction of the charge carriers.[2]. In its simplest form, this may be done with a single

semiconductor 'pellet' which is soldered to electrically-conductive material on each end (usually

plated copper). In this 'stripped-down' configuration, the second dissimilar material required

for the Peltier effect, is actually the copper connection paths to the power supply. It is

important to note that the heat will be moved (or 'pumped') in the direction of charge carrier

flow throughout the circuit— actually, it is the charge carriers that transfer the heat.[3].But in

order to pump appreciable amount of heat, we need to interconnect such semiconductor

electrically and thermally parallel. Moreover it needs costly power supply arrangement to

supply high current requirement for parallel arrangement of semiconductor. So semiconductor

can be arranged electrically in series but thermally parallel which further increases the

possibility of short circuiting and reduces the reliability of system. The best optimized way to

connect the semiconductor is in the form of pn junctions which overcome the above

mentioned problems .[Ref.2]](https://image.slidesharecdn.com/thermoelectriccooler-180425145339/85/Thermoelectric-cooler-3-320.jpg)

![zT for p-type thermoelectric materials [ref3]

Similar results are shown for n-type semiconductors

Bi2Te3 Properties

Below is a plot of the figure of merit (Z), Seebeck coefficient, electrical resistivity, and thermal

conductivity, as a function of temperature for Bi2Te3. Carrier concentration will alter the values below.](https://image.slidesharecdn.com/thermoelectriccooler-180425145339/85/Thermoelectric-cooler-14-320.jpg)

![Although the principle of thermoelectricity dates back to the discovery of the Peltier effect, there was

little practical application of the phenomenon until the middle 1950‟s. Prior to then, the poor thermoelectric

properties of known materials made them unsuitable for use in a practical refrigerating device. According to Nolas

et al [3], from the middle 1950s to the present the major thermoelectric material design approach was that

introduced by A.V. Ioffe, leading to semi-conducting compounds such as Bi2Te3, which is currently used in

thermoelectric refrigerators. In recent years there has been increased interest in the application of thermoelectric

to electronic cooling, accompanied by efforts to improve their performance through the development of new bulk

materials and thin film micro coolers [3]. The usefulness of thermoelectric materials for refrigeration is often

characterized by the dimensionless product, ZT, of the thermoelectric figure of merit Z and temperature T. The

expression for the thermoelectric figure of merit is given by:

Where ρ is the electrical resistivity, k is the thermal conductivity, and is the Seebeck Coefficient.

Note: low electrical resistivity and thermal conductivity are required for high high figure of merit. These

values are temperature dependent therefore, the figure of merit is temperature dependent. P and N

type material have different figures of merit and are averaged to determine a materials overall quality.

Fluerial et al [4] reported that in 1991 JPL started abroad search to identify and develop advanced

materials. Among the materials considered, Skutterudite and Zn4Sb3 based materials appeared

particularly promising and several of these materials are being developed. ZT values equal to or greater

than one have been obtained for these materials over different ranges of temperature varying from 375

to 975K. However, to be particularly useful for electronic cooling applications, improvements in ZT are

needed over the temperature range of 300 to 325K or below. Another strategy for enhancing ZT being

pursued by researchers at MIT, Harvard and UCLA focuses on reduced dimensionality as occurs in

quantum wells (2D) or quantum wires.

Table I Figure of Merit for Different Materials

Material Figure of merit

Pb – Te 1.2 x 10-3

Pb – Se 1.2 x 10-3

k

Z

](https://image.slidesharecdn.com/thermoelectriccooler-180425145339/85/Thermoelectric-cooler-16-320.jpg)

![Pb2 – Te3 1.2 x 10-3

Bi2 – Te3 1.3 x 10-3

(BiSb)2 – Te3 3.3 x 10-3

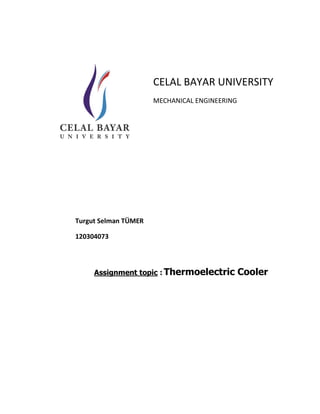

THERMOELECTRIC REFRIGERATORS COMPENENTS

The thermoelectric refrigerator consists of the following components:

A. The Thermoelectric Module

The thermoelectric module consists of pairs of P-type and N-type semi-conductor thermo element forming

thermocouple which are connected electrically in series and thermally in parallel. The modules are considered to

be highly reliable components due to their solid state construction. For most application they will provide long,

trouble free service. In cooling application, an electrical current is supplied to the module, heat is pumped from

one side to the other, and the result is that one side of the module becomes cold and the other side hot.

B. Heat Sink

The heat sink usually made of aluminum, is in contact with the hot side of a thermoelectric module. When the

positive and negative module leads are connected to the respective positive and negative terminals of a Direct

Current (D.C) power source, heat will be rejected by the module‟s hot side, the heat sink expedites the removal of

heat. Heat sink typically is intermediates stages in the heat removal process whereby heat flows into a heat sink

and then is transferred to an external medium. Common heat sinks include free convection, forced convection and

fluid cooled, depending on the size of the refrigerator.

C. Cold Side

The cold side also made of aluminum is in contact with the cold side of a thermoelectric module, when the positive

and negative module leads are connected to the respective positive and negative terminals of a direct current

(D.C) power source, heat will be absorbed by the module‟s cold side. The hot side of a thermoelectric module is

normally placed in contact with the object being cold.

D. Spacer Block

The spacer block though optional in water chillers is used to ensure sufficient air gap between the heat sink and

the object being cooled.

E. Power Source

Thermoelectric module is a Direct Current (D.C) device. Specified thermoelectric module performance is valid if a

Direct Current (D.C) power supply is used. Actual D.C power supply has a rippled output. This D. C. component is

detrimental [7]. Degradation of thermoelectric module performance due to the ripple can be approximated by:](https://image.slidesharecdn.com/thermoelectriccooler-180425145339/85/Thermoelectric-cooler-17-320.jpg)

![quiet, the presence of an AC ripple signal within the module and wire leads may be unsatisfactory. The acceptable

level of power supply ripple for such applications will have to be determined on a case-by-case basis.

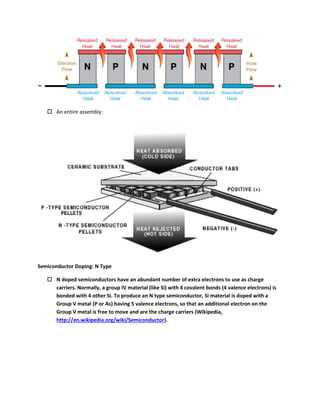

Thermoelectric Performance

TE performance depends on the following factors:

The temperature of the cold and hot sides.

Thermal and electrical conductivities of the device’s materials.

Contact resistance between the TE device and heat source/heat sink.

Thermal resistance of the heat sink.

The current yielding the maximum COP is given by:

The maximum COP is:

Where Tm= (TH+TC)/2

The COP corresponding to the maximum heat pumping capacity is:

The current corresponding to the maximum heat pumping capacity is:

]1)1[(

))((

2/1

m

chnp

ZTR

TT

I

]1)1)[((

]/)1[(

2/1

12

12

2/1

1

max

m

m

in

c

ZTTT

TTZTT

W

Q

cH

cHc

q

TZT

TTZT )(2/1

2

R

T

I

cnp

q

)(

](https://image.slidesharecdn.com/thermoelectriccooler-180425145339/85/Thermoelectric-cooler-23-320.jpg)

![A new approach to increase ZT is to use superlattice structures to reduce k. [5]

In heat conduction, a quantum of vibrational energy is called a phonon, and heat conduction can

be studied as a transport of phonons. To increase ZT, strategies to reduce k and ρ simultaneously have

been very difficult. For example, by making amorphous materials, one can reduce k by introducing many

scattering sites for phonons and thereby reducing l. However, they also scatter electrons and thereby

reduce ρ. Because at the fundamental level, heat conduction by phonons is a wave transport problem,

wave effects are being used to alter heat conduction. One such approach is to fabricate a multi-layer

structure containing extremely thin films of two alternating materials. Such a superlattice should have a

period of 1-10 nm since the wavelength of phonons that dominate in heat conduction fall in this regime.

Phonon wave interference effects in superlattices reduce the propagation speed of phonons and

thereby reduce the effective thermal conductivity. Therefore, as the superlattice period thickness

decreases, thermal resistance increases and the thermal conductivity goes on reducing with increasing

number of such interfaces.

e.g. Using PbTe quantum wells and electron confinement to quantum wells with thickness ranging from

1.7 to 5.5 nm, a factor of 5 increase was found in Z relative to bulk PbTe of the same volume.

Thermal conductivity reduction in this manner is being used in thermoelectric devices to

produce high-performance refrigerators.

Methods like miniaturization and superlattices allow us to manipulate the thermal properties of

materials which can have a strong influence on the performance of thermoelectric refrigeration devices.

Use of PCMs, new materials with unusual electronic and thermal properties and other novel heat

transfer designs significantly increase the C.O.P. of TE devices and thus need to be developed more

vigorously

.

Design Methodology](https://image.slidesharecdn.com/thermoelectriccooler-180425145339/85/Thermoelectric-cooler-27-320.jpg)

![ Laser diodes

Laboratory instruments

Temperature baths

Refrigerators

Telecommunications equipment

Temperature control in missiles and space systems

Heat transport ranges vary from a few milliwatts to several thousand

watts, however, since the efficiency of TE devices are low, smaller heat

transfer applications are more practical.

Commercial devices based on thermoelectric materials have come up in a big way recently. In

addition to the benefits thermoelectrics offer over the conventional devices, commercial factors like

decrease in production costs and significant opening of consumer markets have helped it in a big way

and the use of T.E. devices is increasing day by day.

Thermoelectric cooling is used in medical and pharmaceutical equipment, spectroscopy systems,

various types of detectors, electronic equipment, portable refrigerators, chilled food and

beverage dispensers, and drinking water coolers.

Requiring cooling devices with high reliability that fit into small spaces, powerful integrated

circuits in today's personal computers also employ thermoelectric coolers.

Using solid state heat pumps that utilize the Peltier effect, thermoelectric cooling devices are

also under scrutiny for larger spaces such as passenger compartments of idling aircraft parked at

the gate.

Some of the other potential and current uses of thermoelectric cooling are: [8]

Military/Aerospace](https://image.slidesharecdn.com/thermoelectriccooler-180425145339/85/Thermoelectric-cooler-29-320.jpg)

![available for recreational use.

BATTERY DRAIN: Koolatron coolers have a maximum current drain on 12 volts of 4.5 amps. Compressor

portables draw slightly more current when running but may average slightly less depending on thermostatic

control settings. Absorption portables draw 6.5 to 7.5 amps when running and may average about 5 amps

draw.

BATTERY PROTECTION: Consider the "Battery Saver" option as discussed in the previous section.

COOLING PERFORMANCE: Compressor systems are potentially the most efficient in hot weather. Some

models will perform as a portable freezer and will refrigerate in ambient temperatures of up to 110 degrees

F. Koolatron units will refrigerate in sustained ambient temperatures of up to 95 degrees F. If they are kept

full, they will refrigerate satisfactorily even if peak daytime temperatures reach 110 degrees F because the

contents temperature will lag behind the ambient. The food will be just starting to warm up when the air

cools off in the evening which will bring the food temperature back down to normal. Absorption type

refrigerators provide almost the same cooling performance as Koolatron portables but are less efficient at

high ambients.

FREEZING ICE CUBES: Compressor systems will usually make a quantity of small ice cubes except in very hot

weather. Gas absorption systems can do the same except in hot weather. Koolatron thermoelectric units do

not make ice cubes but can preserve them in a plastic container for 2 - 3 days which is often adequate for

most applications.

SAFETY: Koolatron systems are completely safe because they use no gases or open flames and run on just 12

volts. Compressor systems can leak freon which can be extremely dangerous especially if heated. Absorption

systems may use propane which can be extremely dangerous in the event of a leak.

RELIABILITY: Koolatrons thermoelectric modules do not wear out or deteriorate with use. They have been

used for military and aerospace applications for years because of their reliability and other unique features.

Compressors and their motors are both subject to wear and freon-filled coils are subject to leakage and

costly repairs. Absorption units are somewhat temperamental and may require expert servicing from time to

time, especially if jarred when travelling.

EASE OF SERVICING AND MAINTENANCE: Koolatron units have only one moving part, a small fan (and 12 volt

motor) which can easily be replaced with only a screw driver. Most parts are easily replaced by the end-user.

Compressor and absorption units both require trained (expensive) mechanics and special service equipment

to service them.

Since thermoelectric cooling systems are most often compared to conventional systems,

perhaps the best way to show the differences in the two refrigeration methods is to describe the

systems themselves.[1] A conventional cooling system contains three fundamental parts - the

evaporator, compressor and condenser. The evaporator or cold section is the part where the](https://image.slidesharecdn.com/thermoelectriccooler-180425145339/85/Thermoelectric-cooler-32-320.jpg)

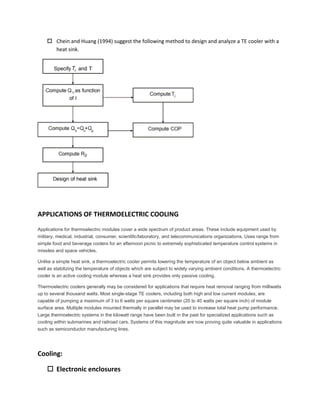

![= 0.0315 Ω

Conduction coefficient (C) = (kp + kn) (A/L)

= (0.02 + 0.02) (7.854 x 10-3 /0.125)

= 2.513 x 10-3 W/K

Figure of merit (Z) = (αp - αn) 2/ RC

= (360 x 10-6) 2 / (0.0315 x 2.513 x 10-3)

= 1.636 x 10-3 K-1

1- Number of couples required.

QC = QC (max) = N C [(Z Tc 2 )/2 – (Th – Tc)] 10

= N (2.513 x 10-3) [0.5 (1.636 x 10-3 x (311)2 ) – (14)]

N ≈ 62 couples

2- Rate of heat rejection to the ambient (Qh).

Iopt. = (αp - αn) Tc /R

= (360 x 10-6) x 311/ 0.0315

= 3.55 A

Then

Qh = N [(αp - αn) Th x Iopt – C (Th – Tc) + I2 opt R/2]

= 62 [(360 x 10-6) 325 x 3.55 - 2.513 x 10-3 (14) + (3.55)2 0.0315/2]

= 35.8 W](https://image.slidesharecdn.com/thermoelectriccooler-180425145339/85/Thermoelectric-cooler-36-320.jpg)