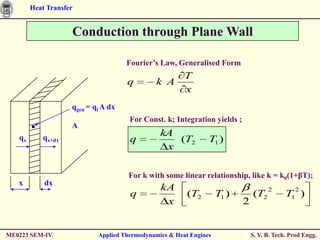

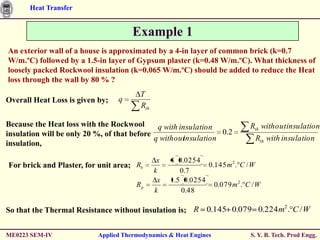

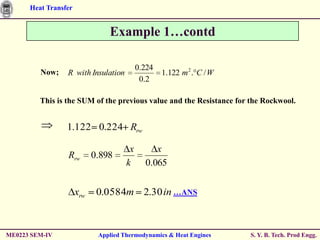

The document discusses heat transfer through conduction, convection and radiation. It covers key concepts like Fourier's law of heat conduction, thermal conductivity of solids, liquids and gases, one dimensional and radial heat conduction, and heat transfer through composite walls. It also provides examples of calculating heat transfer through plane and cylindrical walls, determining the required thickness of insulation, and calculating critical thickness of insulation.

![Heat Transfer

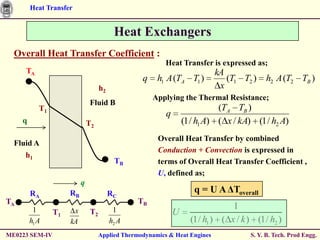

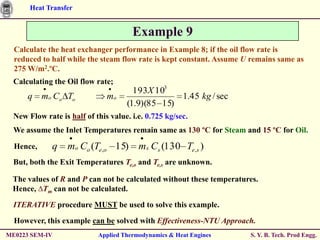

Effectiveness-NTU Method

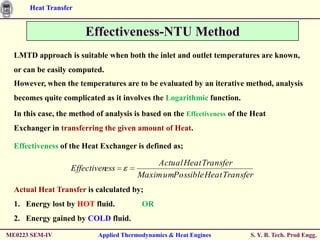

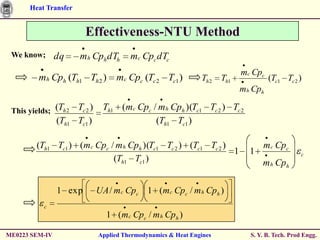

Heat Exchanger Effectiveness Relations :

N = NTU = UA/Cmin C = Cmin/Cmax

Flow Geometry Relation

Double Pipe :

1 exp[ N (1 C )]

Parallel Flow 1 C

1 exp[ N (1 C )]

Counter Flow

1 C exp[ N (1 C )]

N

Counter Flow, C = 1 N 1

Cross Flow :

exp( NCn) 1 0.22

Both Fluids Mixed 1 exp where n N

Cn 1

1 C 1

Both Fluids Unmixed

1 exp( N ) 1 exp( NC ) N

Cmax mixed, Cmin Unmixed (1/ C){ exp[ C(1 e N )]}

1

Cmax Unmixed, Cmin Mixed 1 exp{ (1 / C )[1 exp( NC )]}

Shell-and-Tube :

1

2 1/ 2 1 exp[ N (1 C 2 )1/ 2 ]

1 Shell-pass; 2/4/6 Tube-pass 2 1 C (1 C ) X

1 exp[ N (1 C 2 )1/ 2 ]

All Exchangers, C = 0 : 1 e N

ME0223 SEM-IV Applied Thermodynamics & Heat Engines S. Y. B. Tech. Prod Engg.](https://image.slidesharecdn.com/seprodthermochapter3ht-110220042722-phpapp02/85/Thermodynamics-Chapter-3-Heat-Transfer-77-320.jpg)

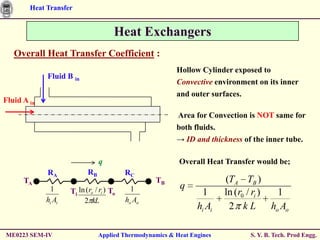

![Heat Transfer

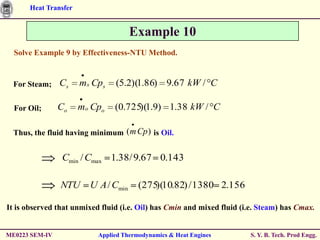

Effectiveness-NTU Method

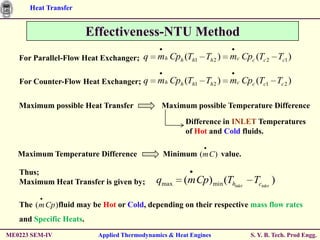

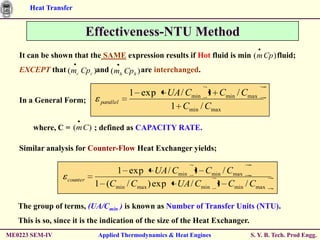

Heat Exchanger NTU Relations :

N = NTU = UA/Cmin C = Cmin/Cmax ε = Effectiveness

Flow Geometry Relation

Double Pipe :

ln[1 (1 C ) ]

Parallel Flow N

1 C

Counter Flow 1 1

N ln

C 1 C 1

Counter Flow, C = 1 N

1

Cross Flow :

1

Cmax mixed, Cmin Unmixed N ln 1 ln (1 C )

C

1

Cmax Unmixed, Cmin Mixed N ln [1 C ln (1 )]

C

Shell-and-Tube :

2 1/ 2 (2 / ) 1 C (1 C 2 )1/ 2

1 Shell-pass; 2/4/6 Tube-pass N (1 C ) X ln

(2 / ) 1 C (1 C 2 )1/ 2

All Exchangers, C = 0 : N ln (1 )

ME0223 SEM-IV Applied Thermodynamics & Heat Engines S. Y. B. Tech. Prod Engg.](https://image.slidesharecdn.com/seprodthermochapter3ht-110220042722-phpapp02/85/Thermodynamics-Chapter-3-Heat-Transfer-78-320.jpg)

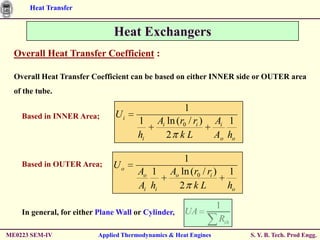

![Heat Transfer

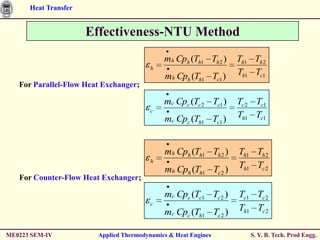

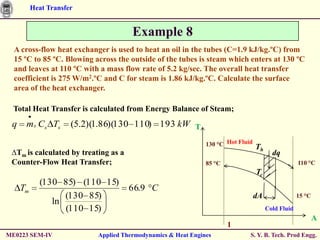

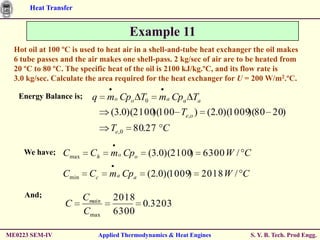

Example 10….contd

Hence; from the Table; we get;

(1 / C ){1 exp[ C (1 e N )]}

2.156

(1 / 0 / 143) 1 exp[ (0.143)(1 e )] 0.831

Using the Effectiveness, we can calculate the Temperature Difference for Oil as;

To ( Tmax ) (0.831 130 15) 95.5 C

)(

Thus, the Heat Transfer is;

q mo Cpo To (1.38)(95.5) 132 kW

Thus,

Reduction in Oil flow rate by 50 % results in reduction in Heat Transfer by 32 % only.

S. Y. B. Tech. Prod Engg.](https://image.slidesharecdn.com/seprodthermochapter3ht-110220042722-phpapp02/85/Thermodynamics-Chapter-3-Heat-Transfer-83-320.jpg)

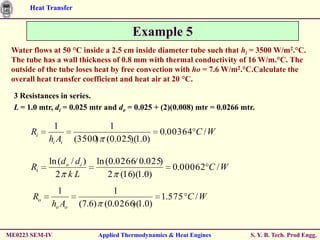

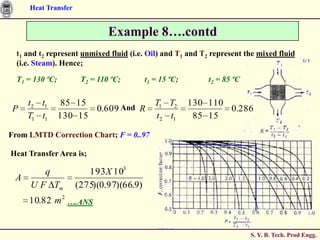

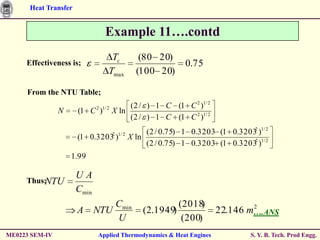

![Heat Transfer

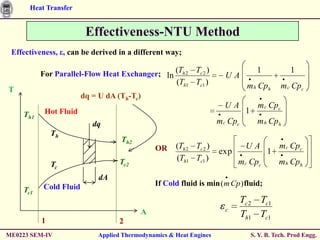

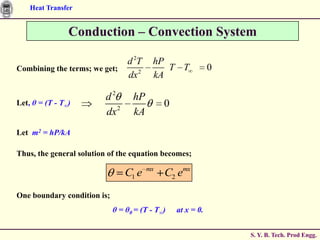

Conduction – Convection System

For CASE 3, Boundary Conditions are : θ = θ0 = (T - T∞) at x = 0.

dθ/dx = 0 at x = L.

This yields;

0 C1 C2

mL

0 m ( C1 e C2 e mL )

e mx emx cosh[m ( L x)]

Solving for C1 and C2, we get;

0 1 e 2mL 1 e2mL cosh (mL)

where, the hyperbolic functions are defined as;

ex e x

ex e x

ex e x

sinh x cosh x tanh x

2 2 ex e x

ME0223 SEM-IV Applied Thermodynamics & Heat Engines S. Y. B. Tech. Prod Engg.](https://image.slidesharecdn.com/seprodthermochapter3ht-110220042722-phpapp02/85/Thermodynamics-Chapter-3-Heat-Transfer-94-320.jpg)

![Heat Transfer

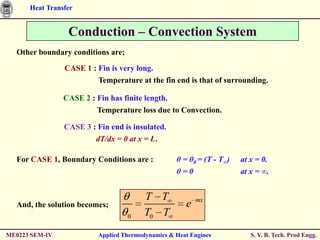

Conduction – Convection System

Solution for CASE 2 is;

T T cosh[m ( L x)] (h / mk )sinh[m ( L x)]

T0 T cosh (mL) (h / mk )sinh (mL)

All the Heat loss by the fin MUST be conducted to the base of fin at x = 0.

dT

Thus, the Heat loss is; qx dx kA

dx x 0

Alternate method of integrating Convection Heat Loss;

L L

q h P (T T ) dx h P dx

0 0

ME0223 SEM-IV Applied Thermodynamics & Heat Engines S. Y. B. Tech. Prod Engg.](https://image.slidesharecdn.com/seprodthermochapter3ht-110220042722-phpapp02/85/Thermodynamics-Chapter-3-Heat-Transfer-95-320.jpg)

![Heat Transfer

Conduction – Convection System

Application of Conduction equation is easier than that for Convection.

m(0)

For CASE 1 : q k A[ m 0e ] h Pk A 0

1 1

q kA 0m

1 e 2 mL 1 e 2 mL

For CASE 3 :

hPk A 0 tanh (mL)

sinh (mL) (h / mk ) cosh (mL)

For CASE 2 : q hPk A 0

cosh (mL) (h / mk )sinh (mL)

ME0223 SEM-IV Applied Thermodynamics & Heat Engines S. Y. B. Tech. Prod Engg.](https://image.slidesharecdn.com/seprodthermochapter3ht-110220042722-phpapp02/85/Thermodynamics-Chapter-3-Heat-Transfer-96-320.jpg)