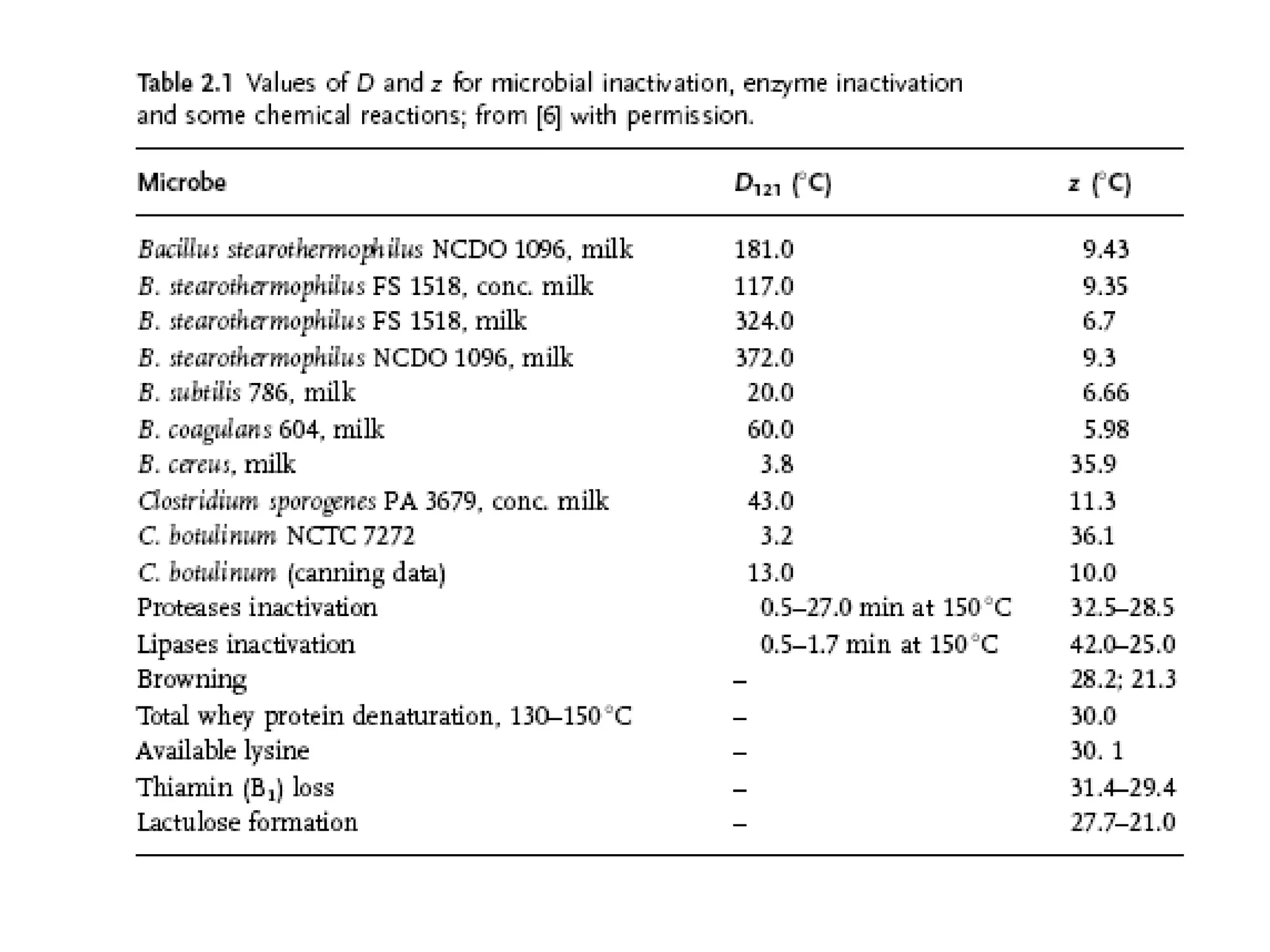

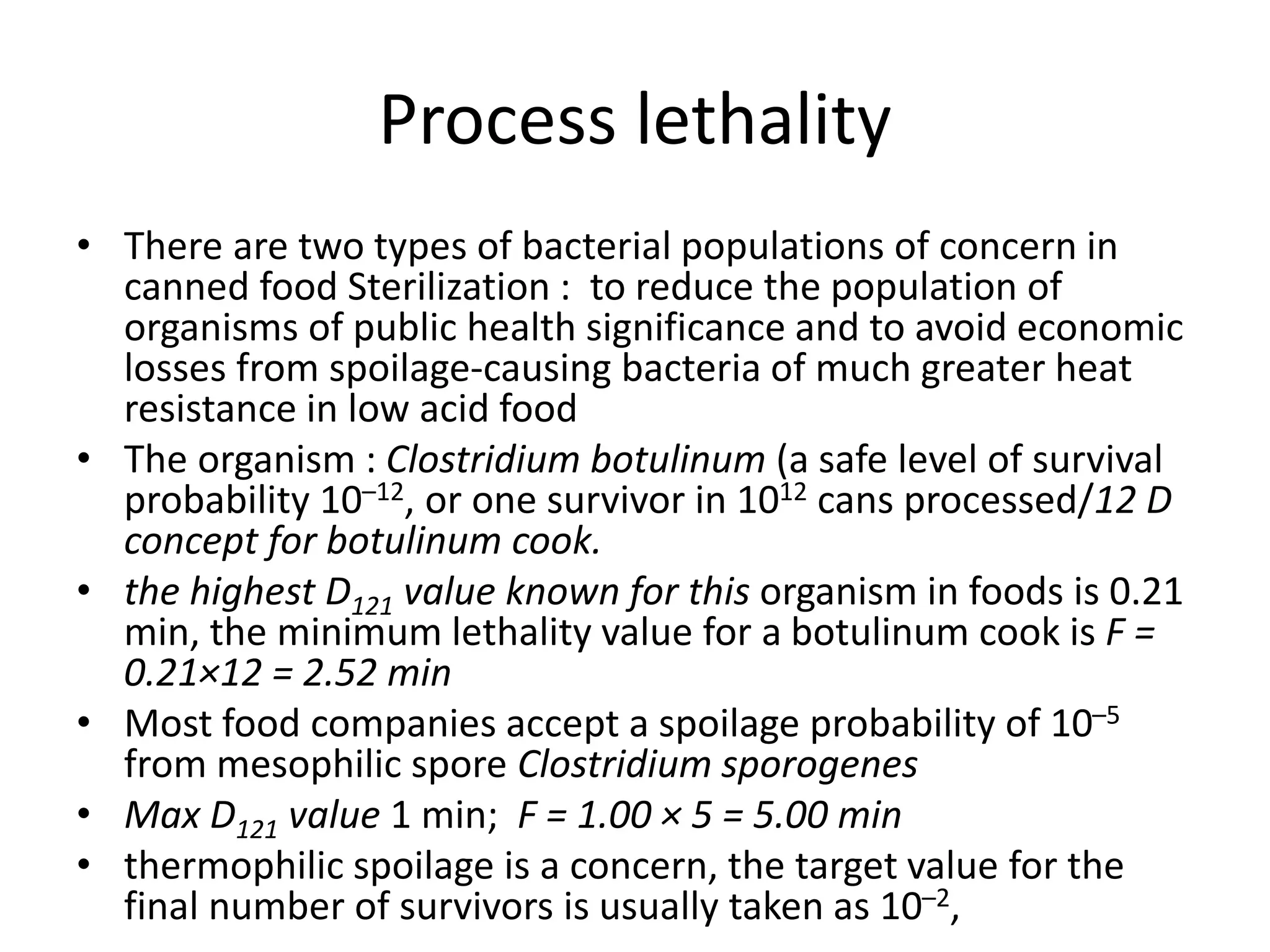

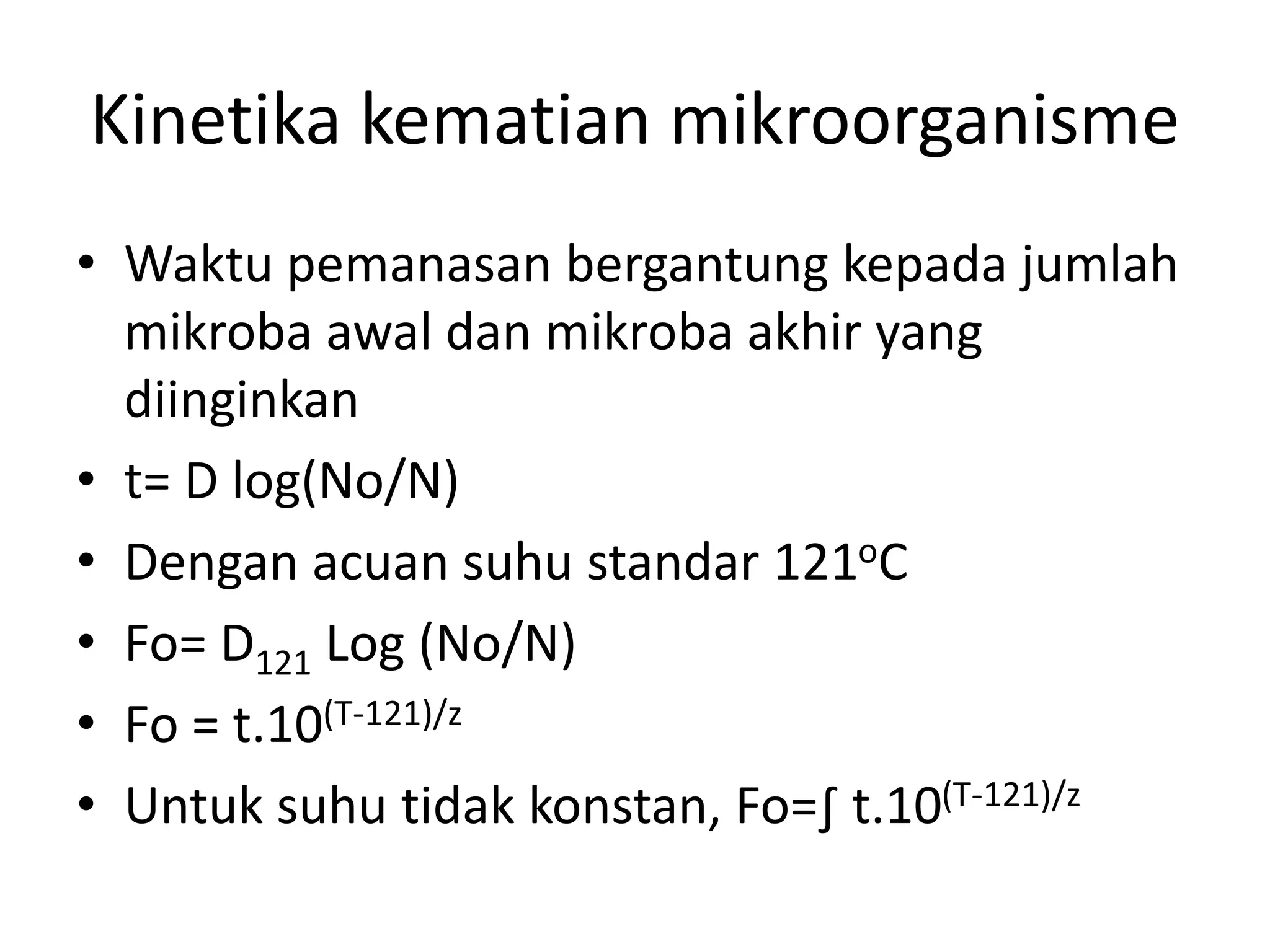

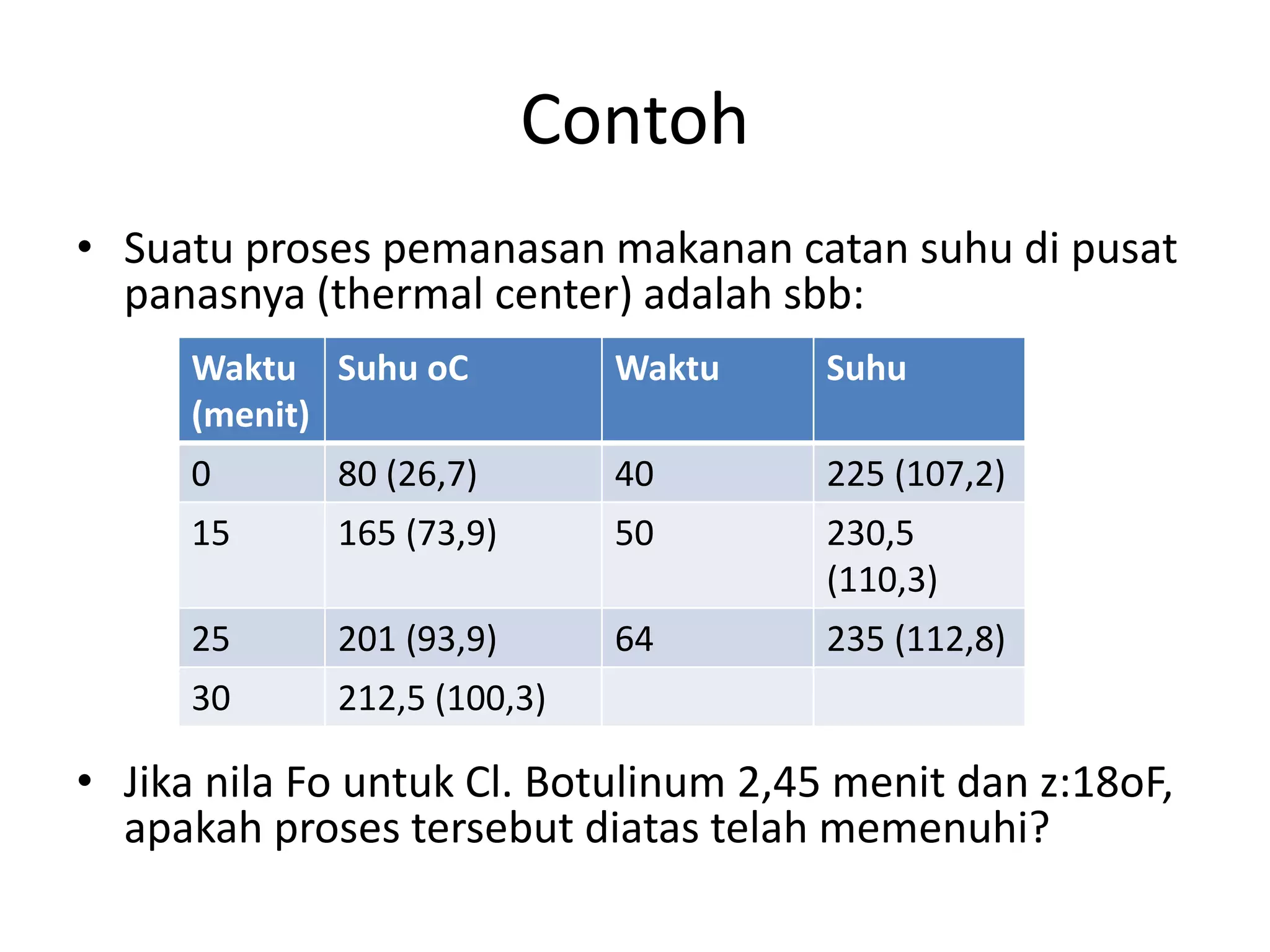

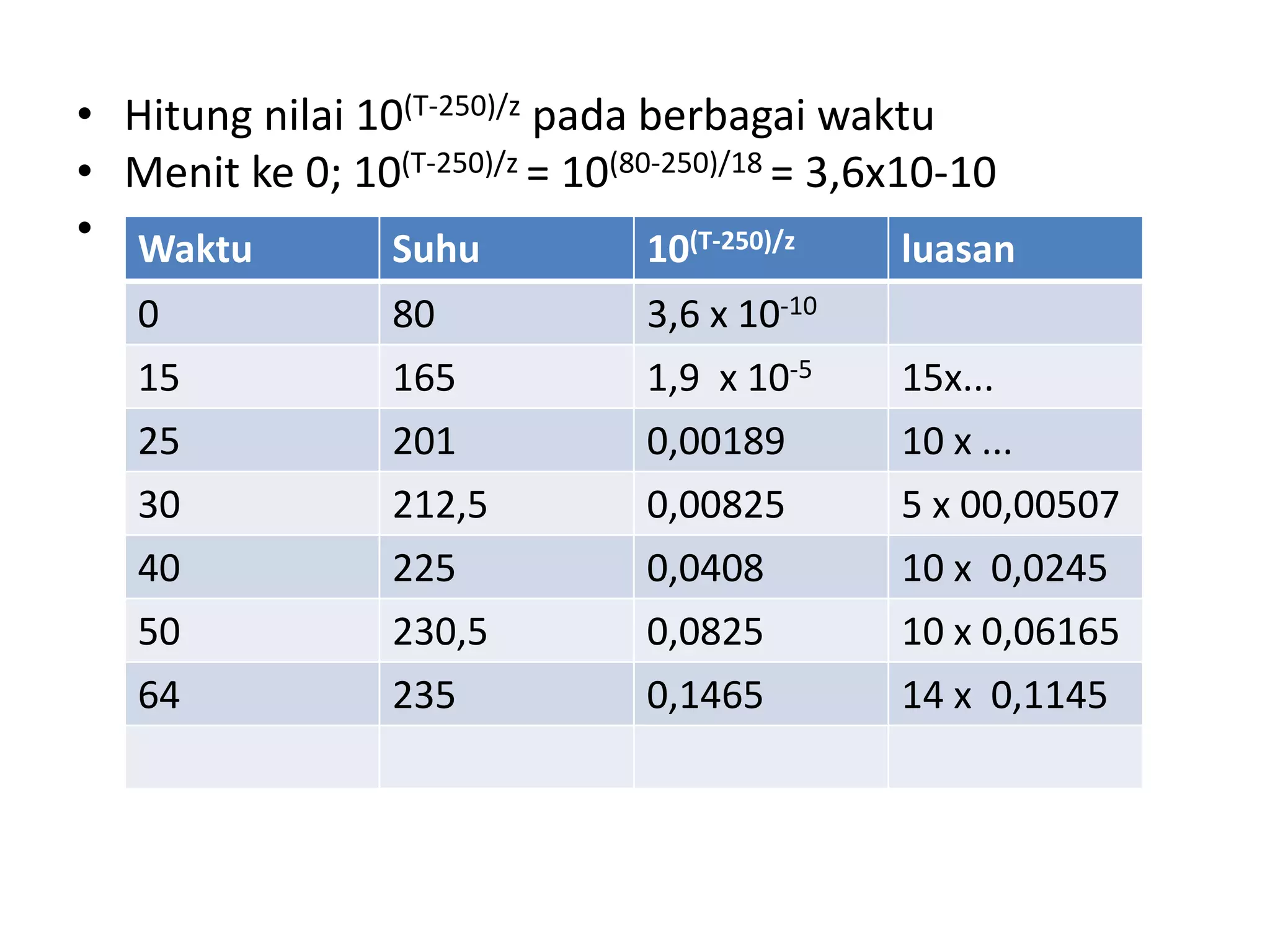

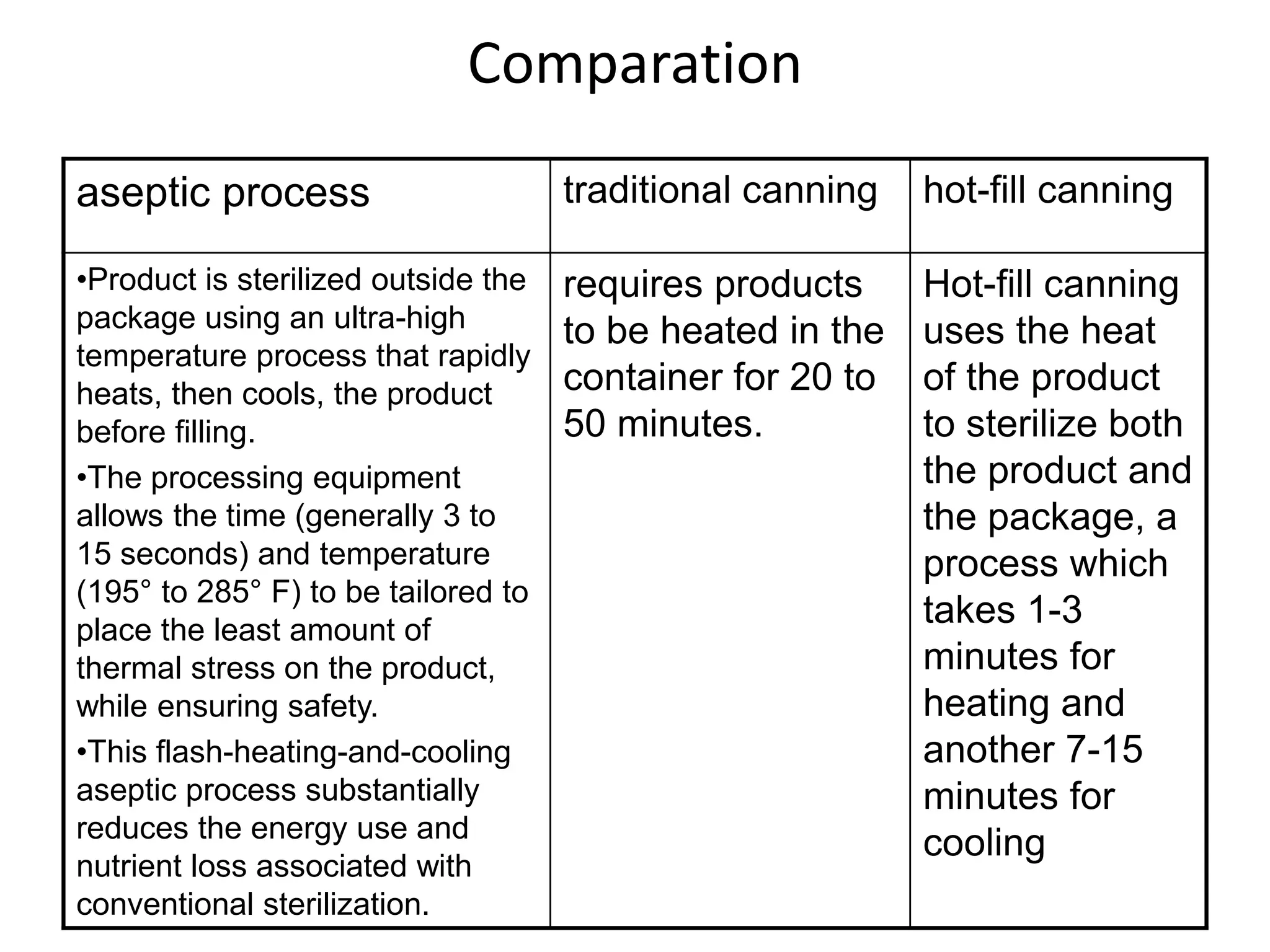

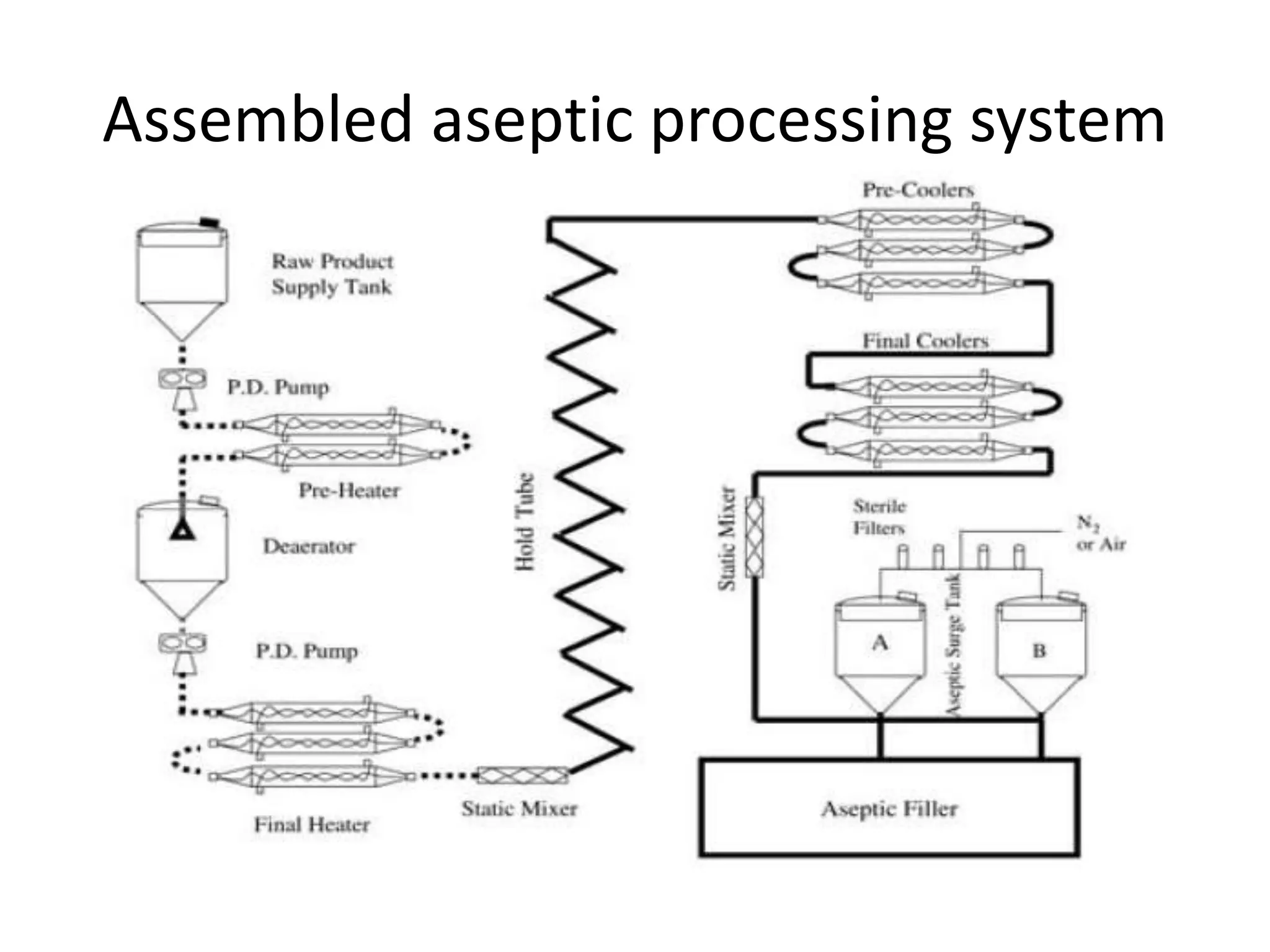

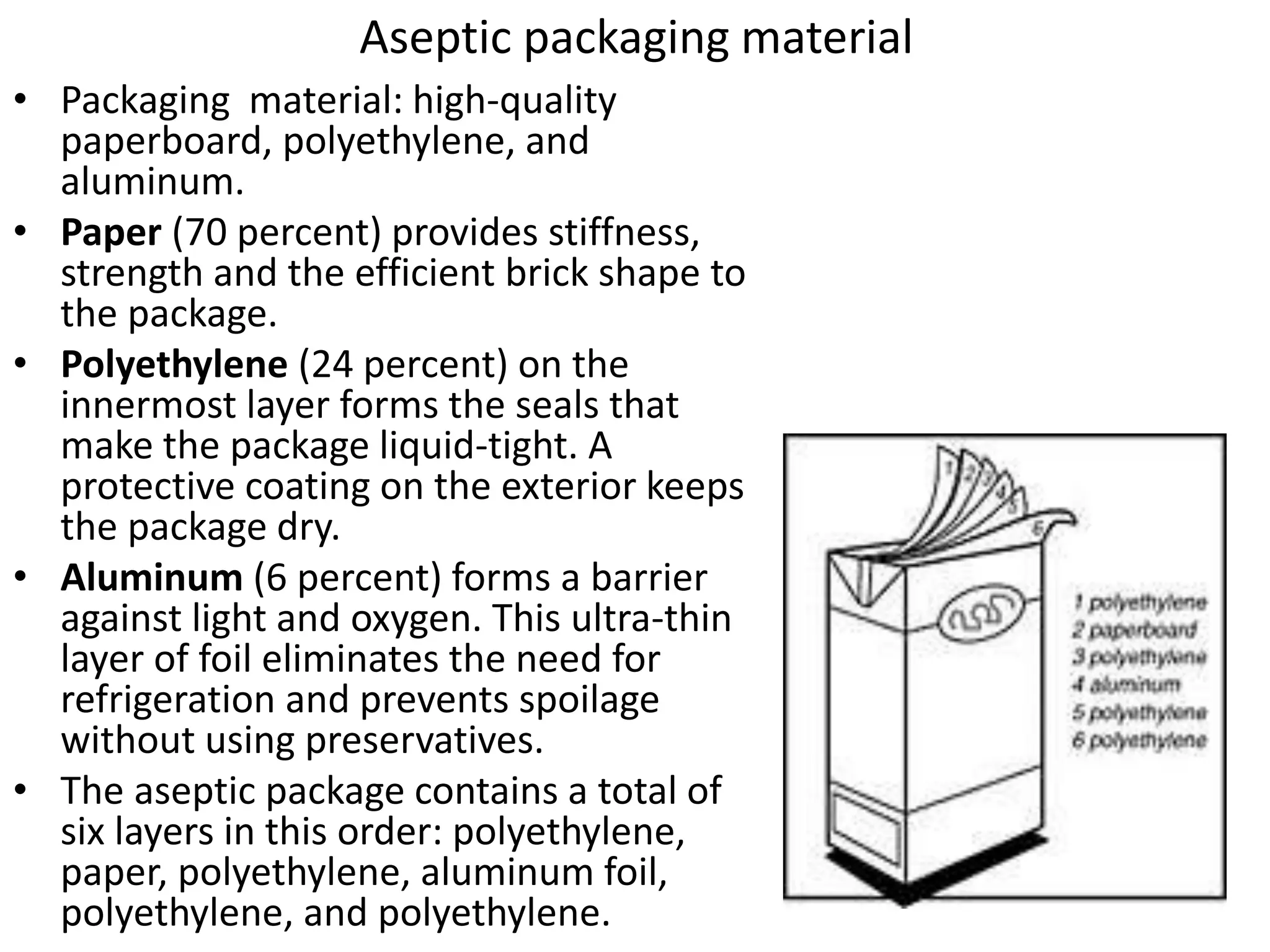

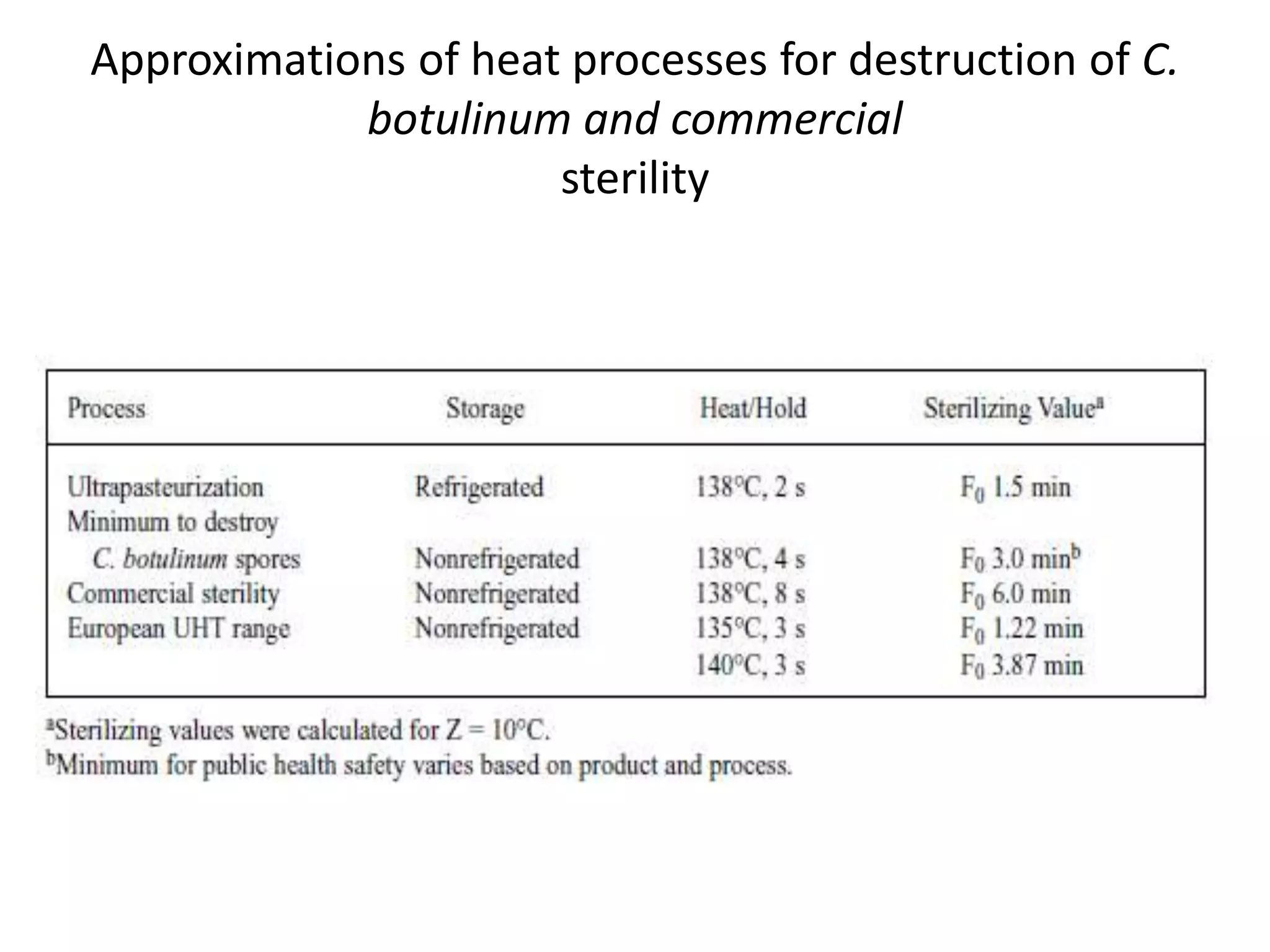

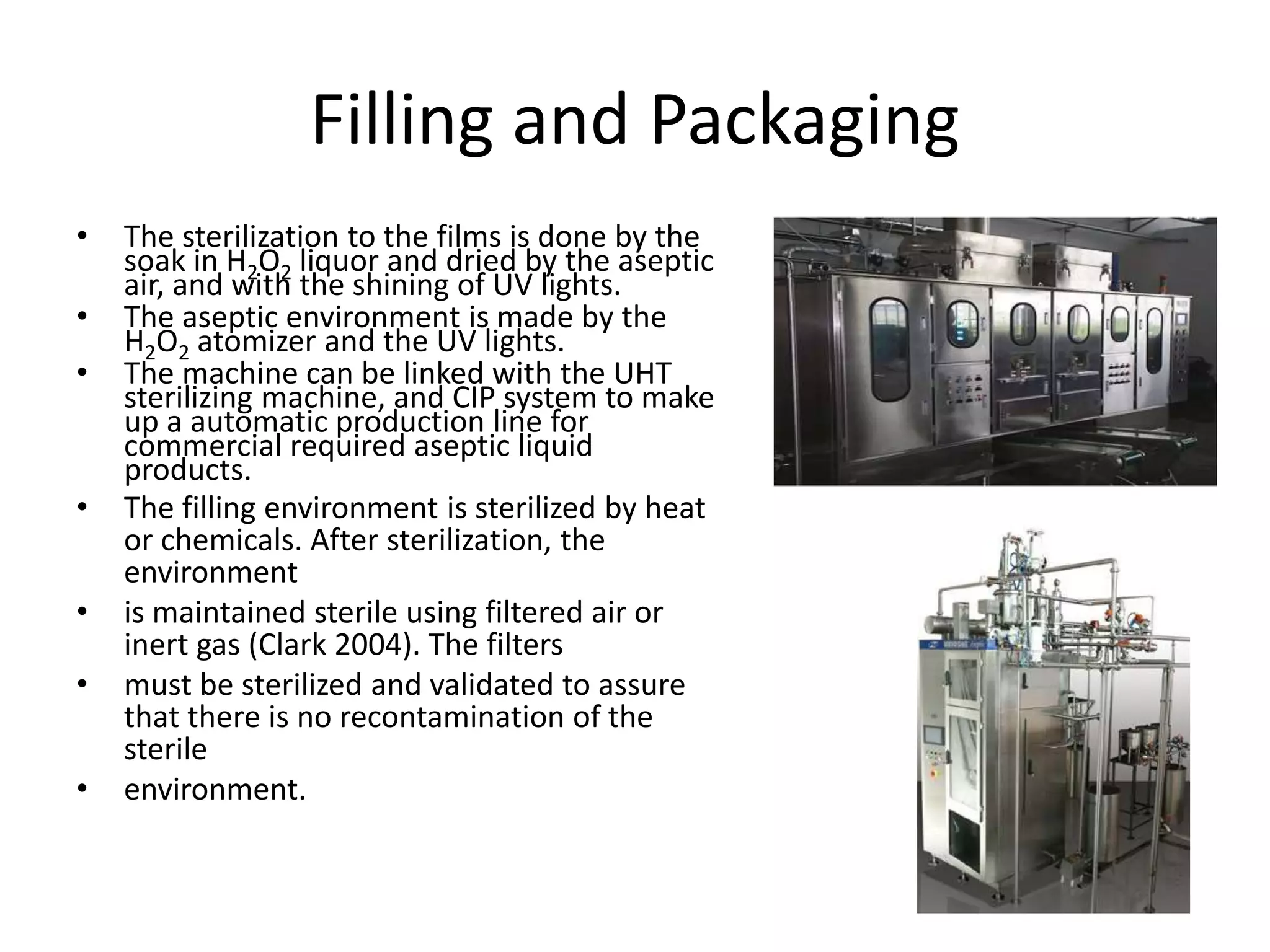

Thermal processing involves heating foods to ensure adequate heat treatment and reduce post-processing contamination. It is important for food safety and quality by inactivating pathogens and enzymes. Different microorganisms have varying heat resistance. Aseptic processing sterilizes pumpable foods outside containers followed by filling under sterile conditions, allowing room temperature storage without refrigeration. Key factors are rapid heating/cooling to minimize quality changes and continuous processing for uniform products. Packaging materials are sterilized by irradiation, heat or chemicals before filling under sterile conditions.