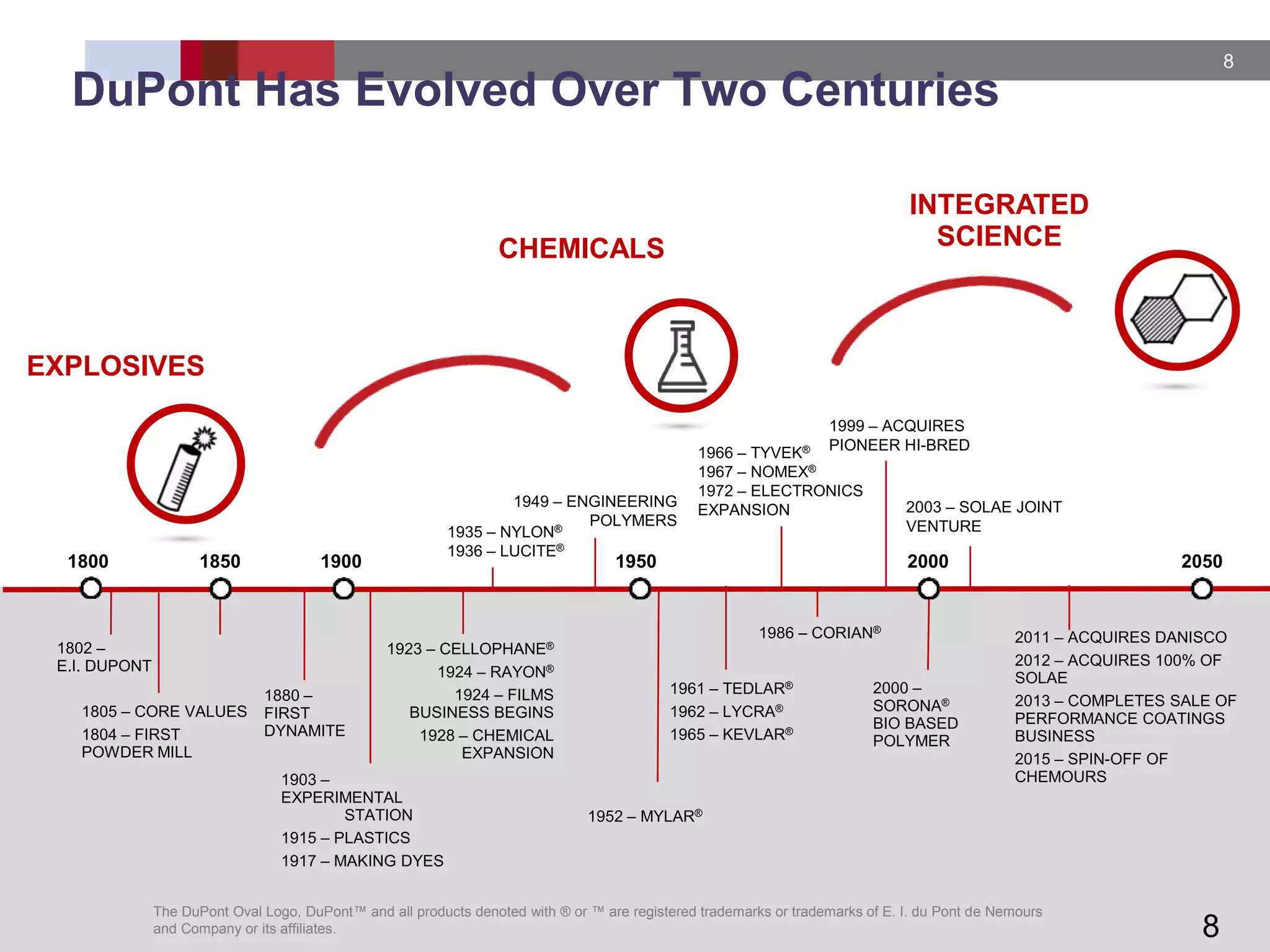

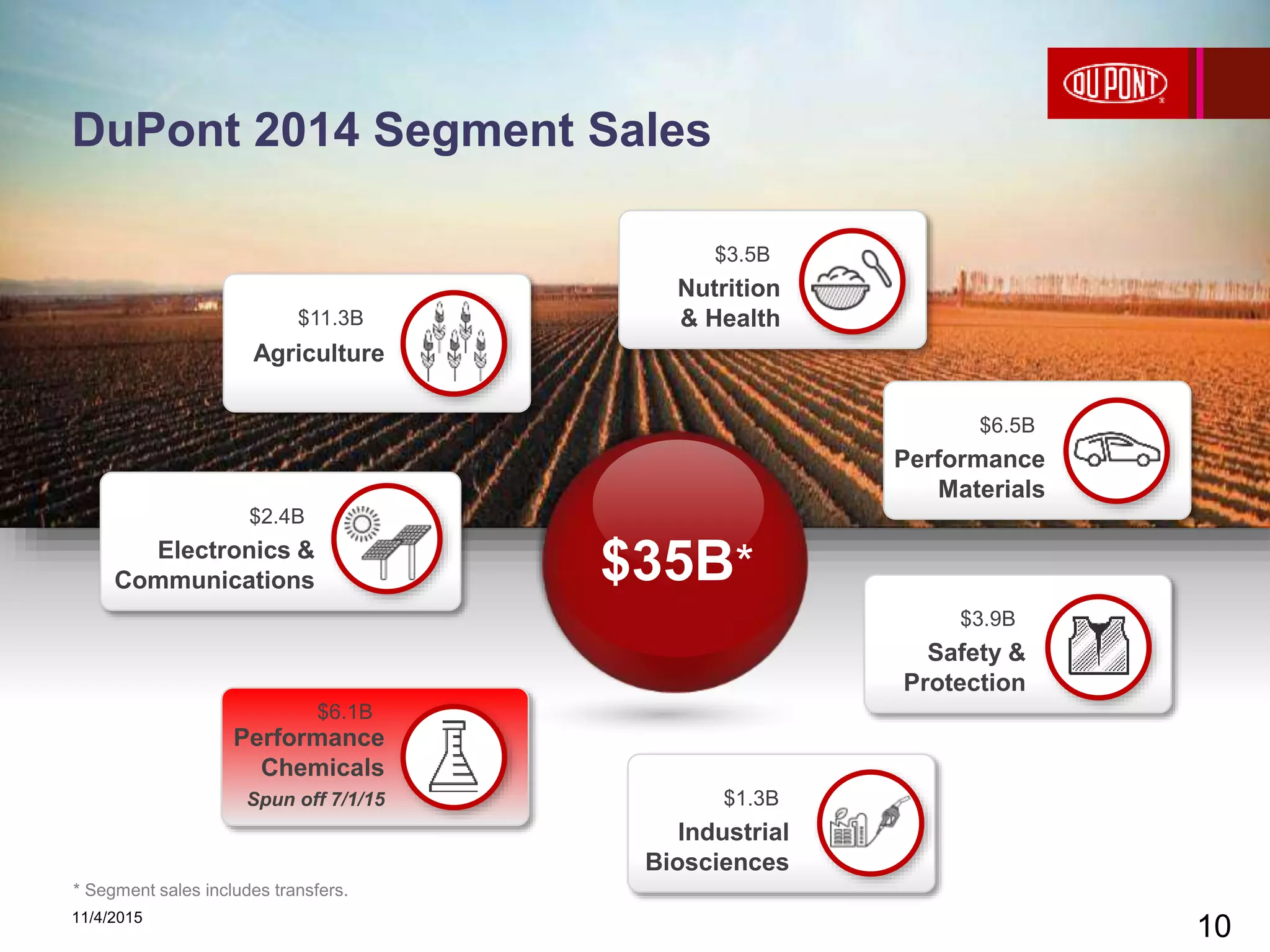

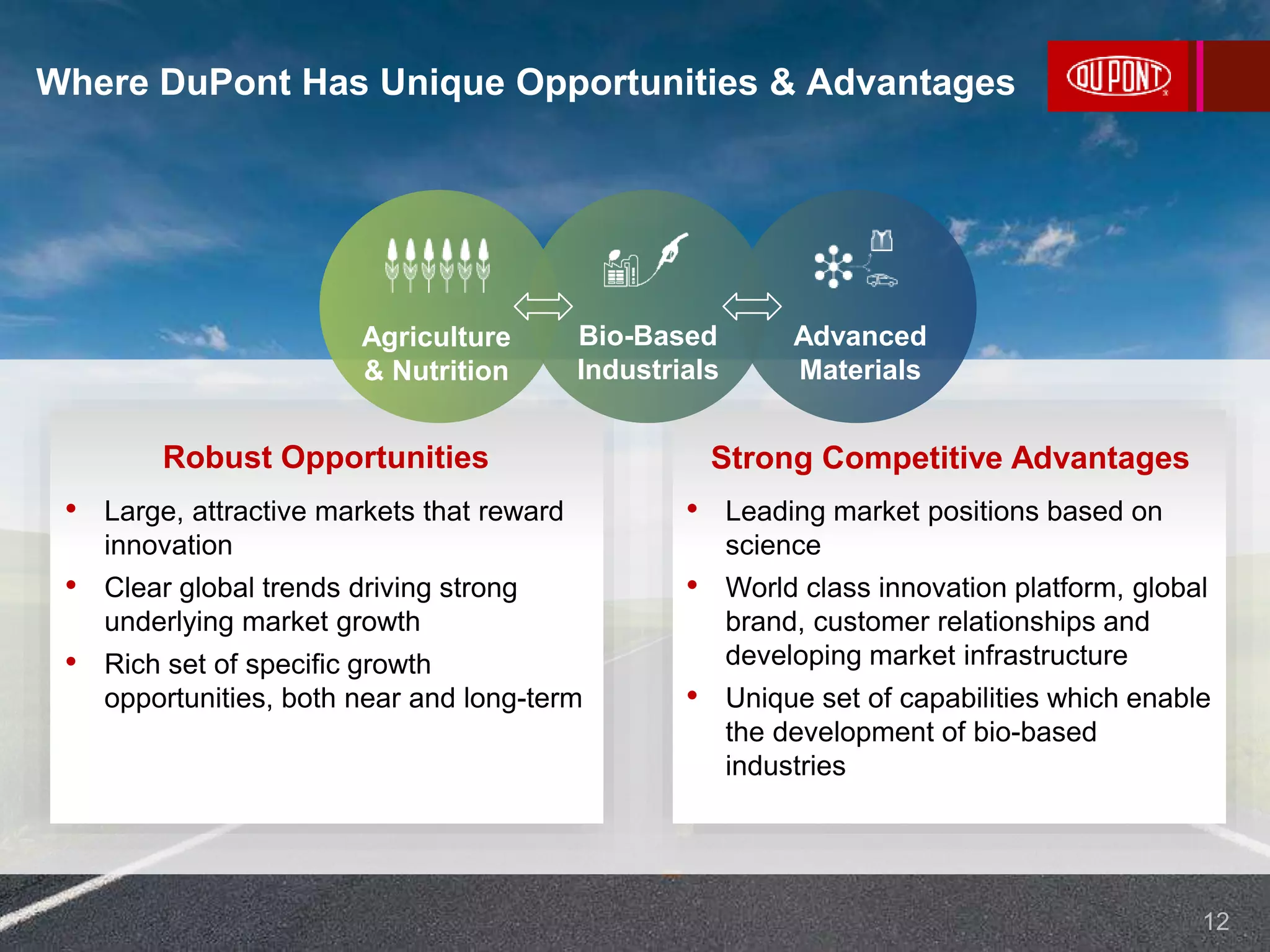

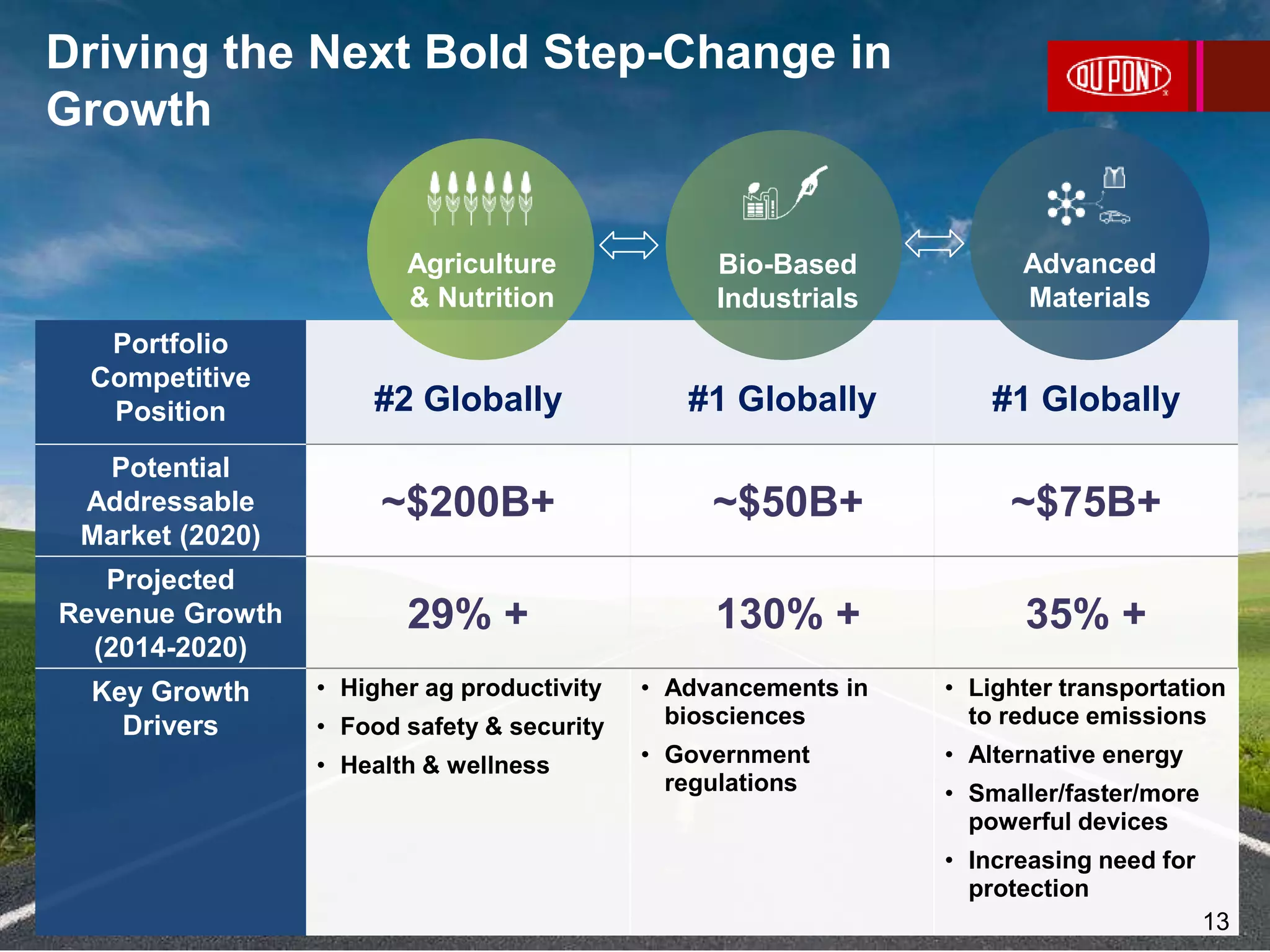

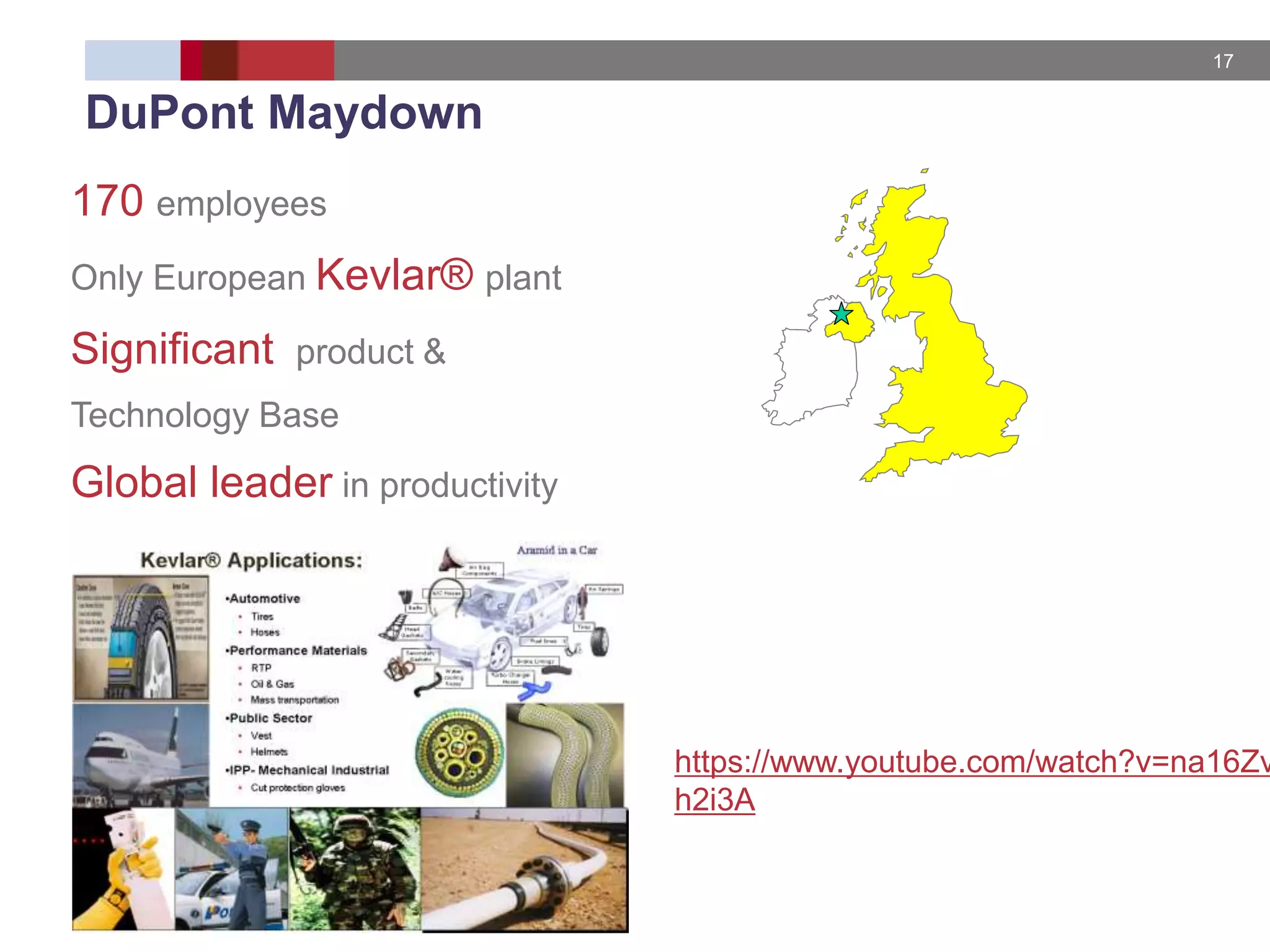

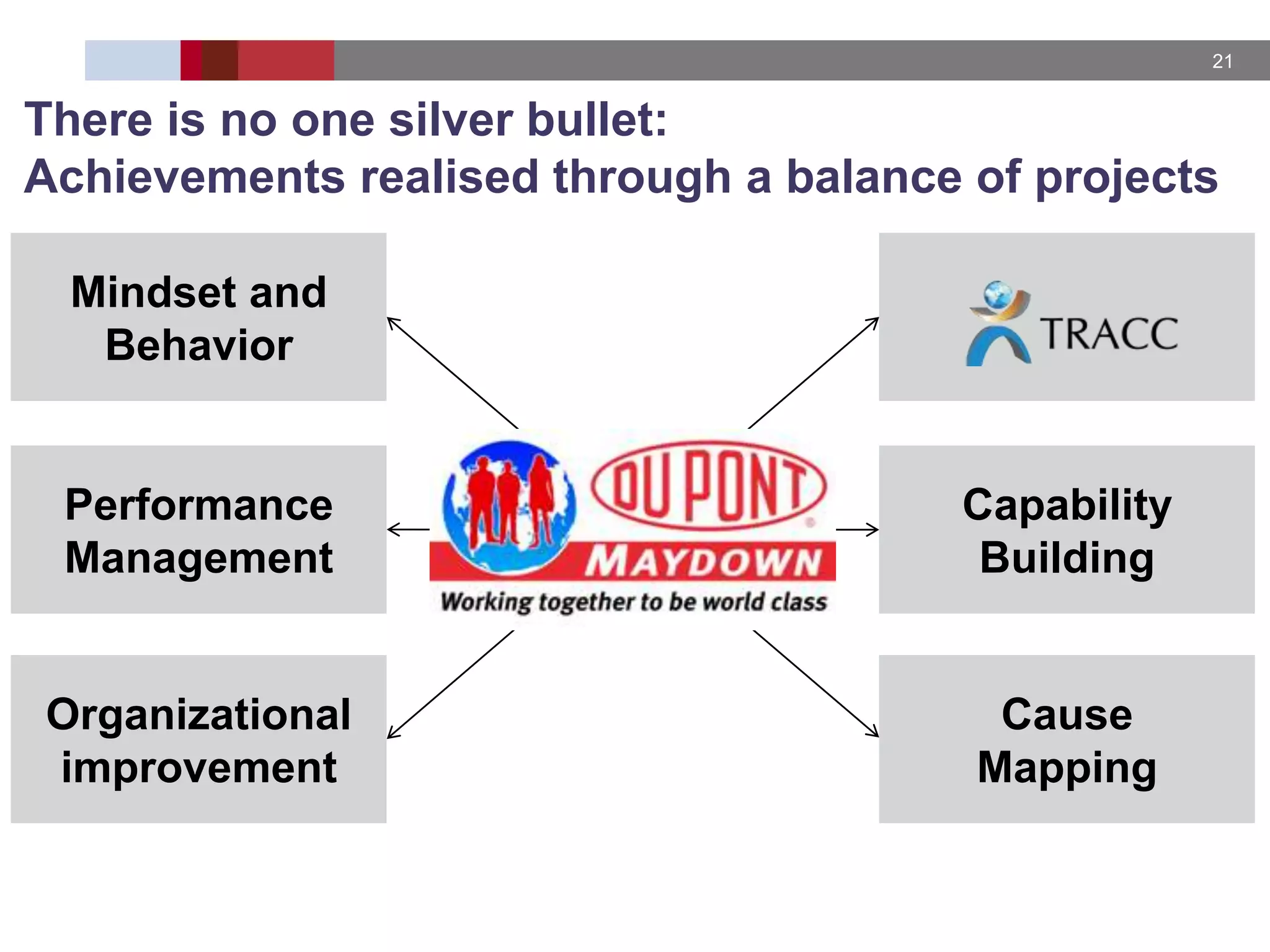

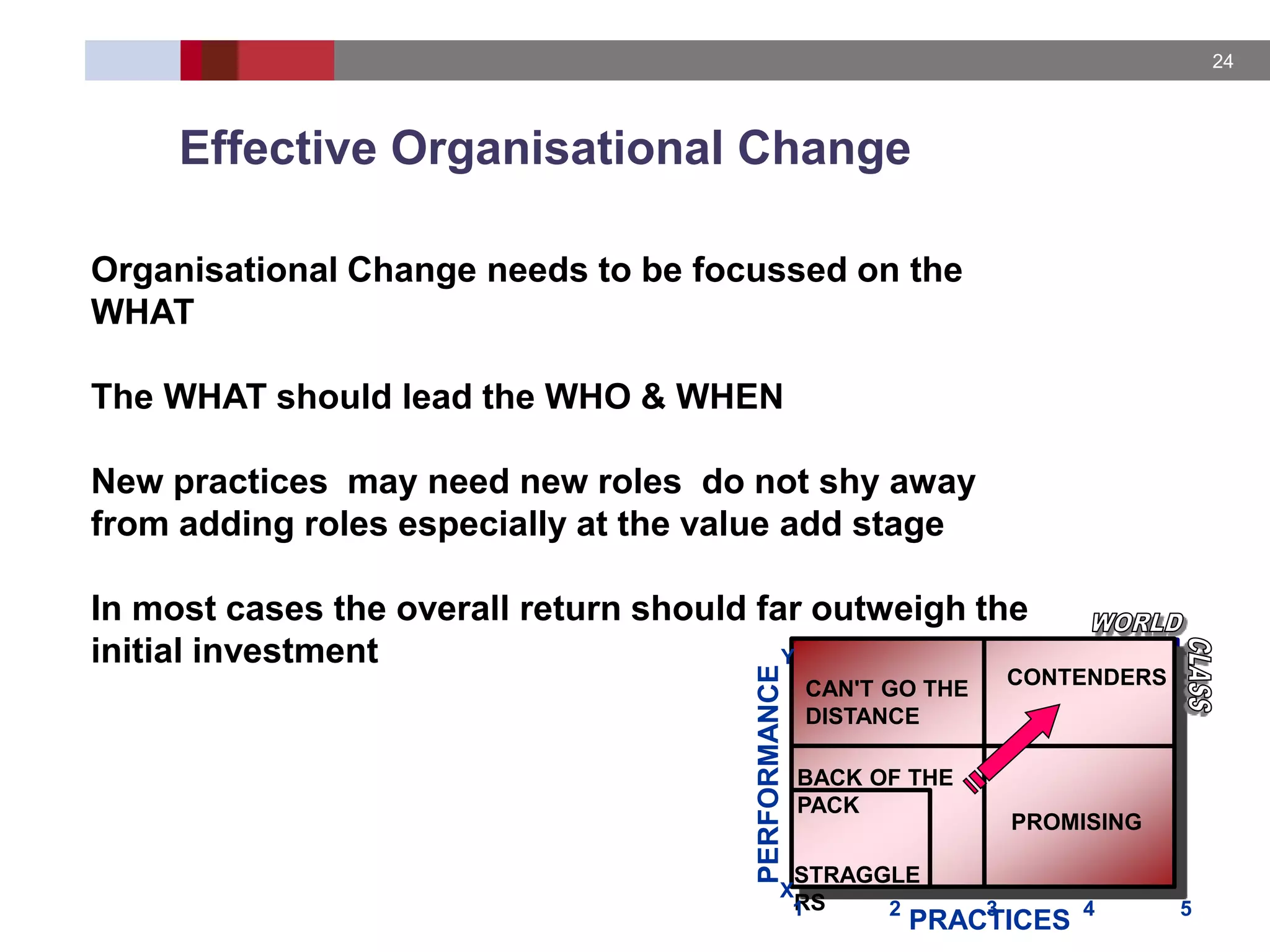

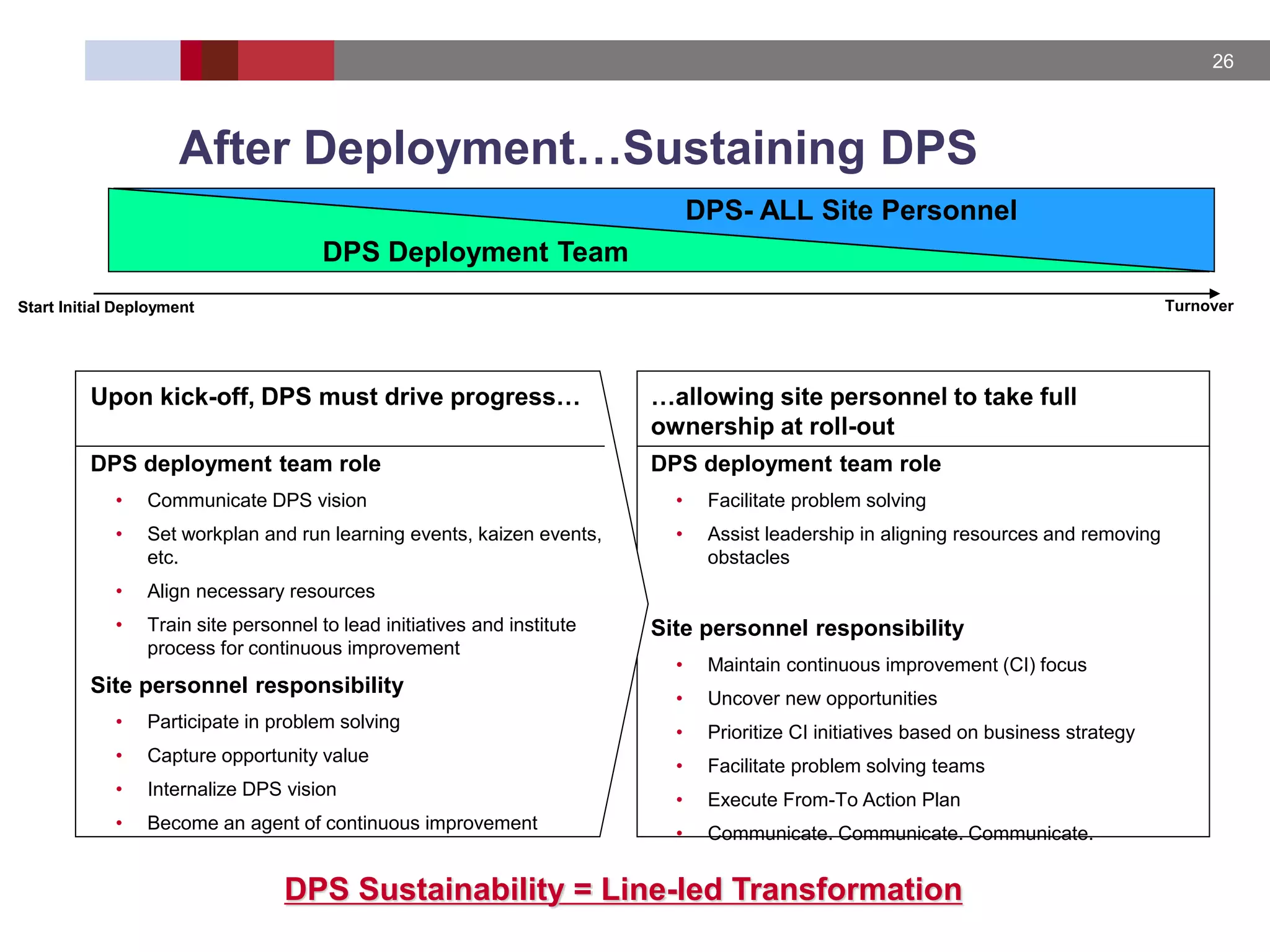

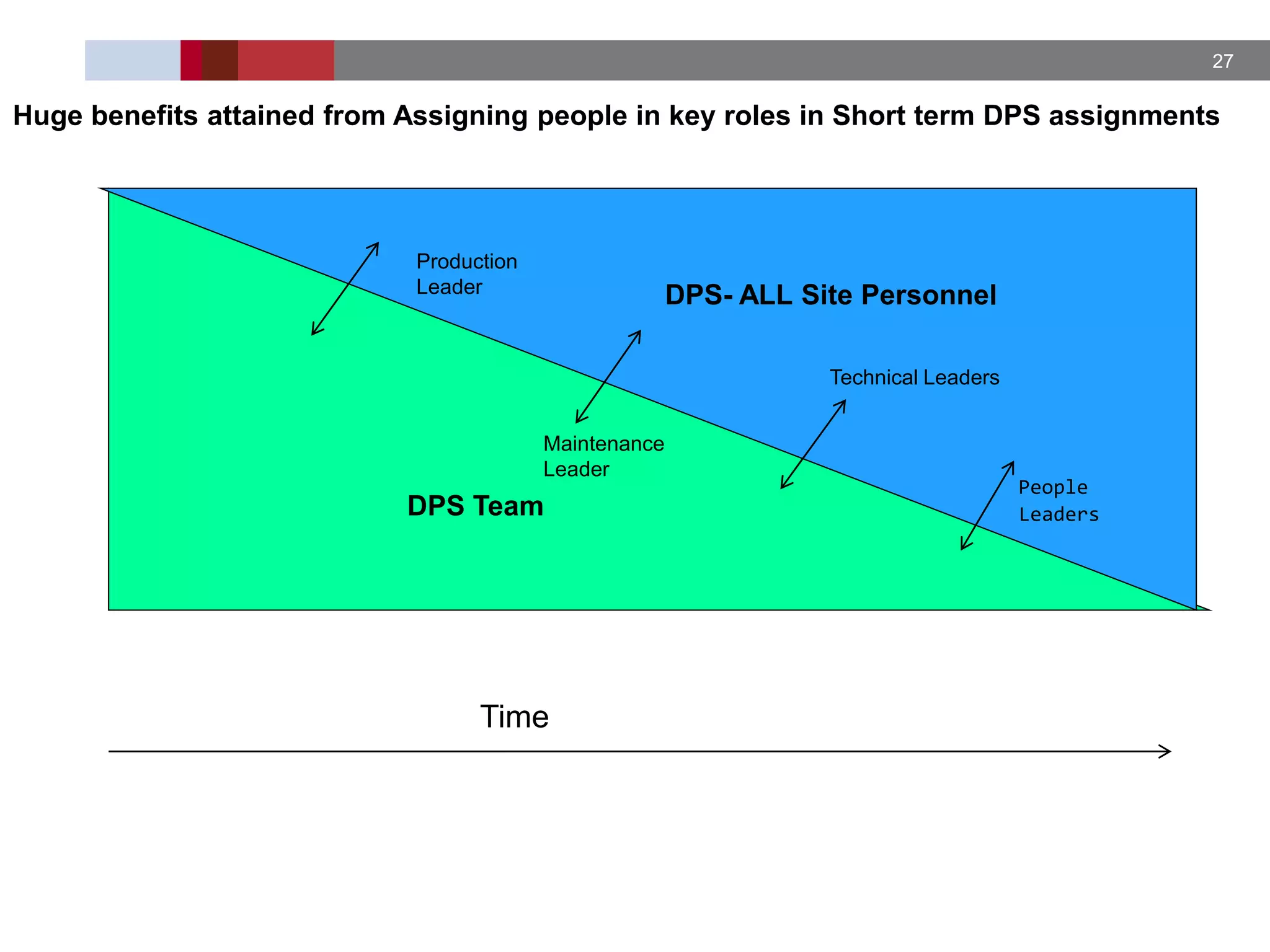

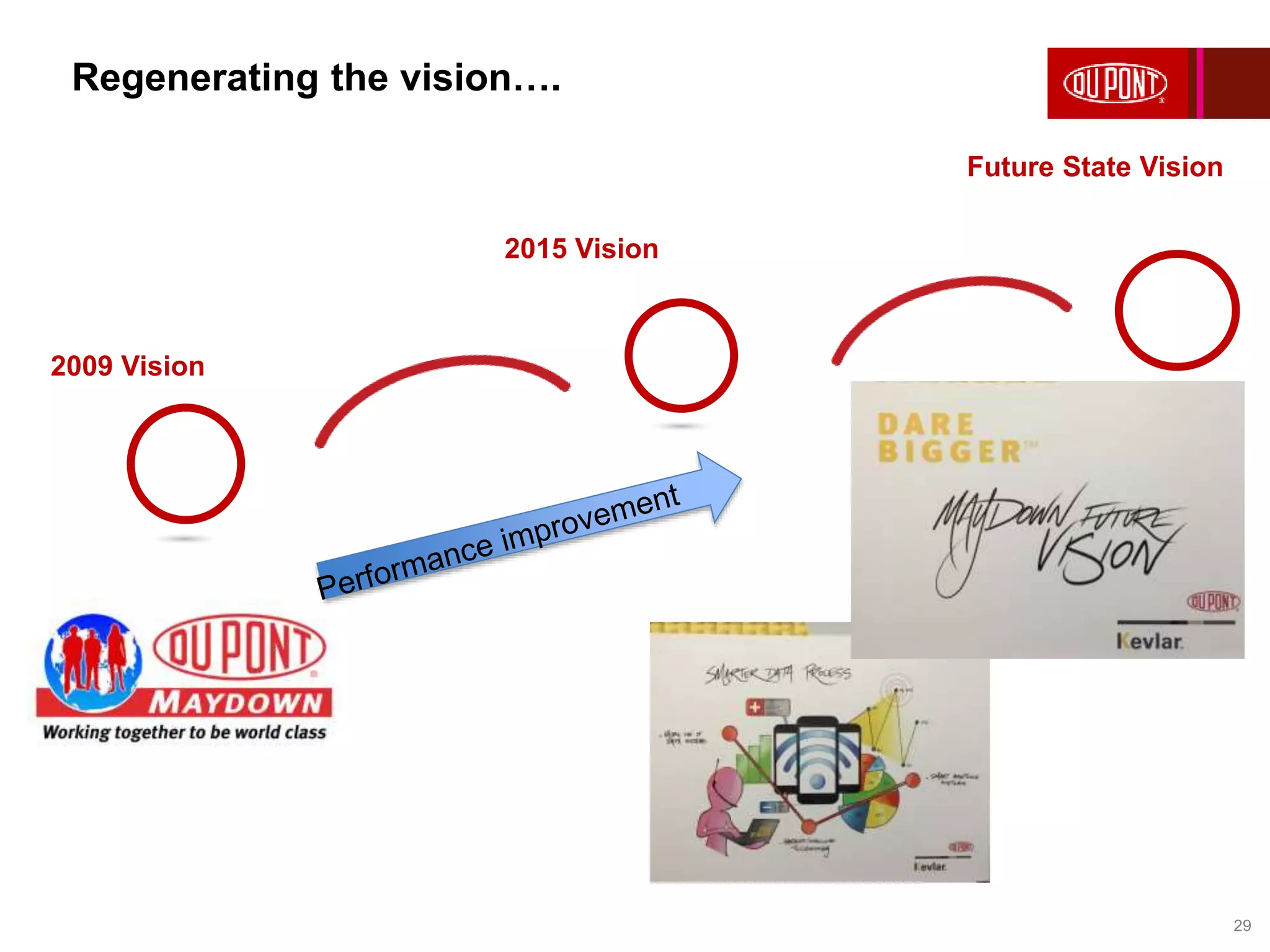

The document discusses the implementation of the DuPont Production System (DPS) at the Maydown facility in Northern Ireland, highlighting the significant improvements in productivity, safety, and quality since its launch in 2009. It outlines DuPont's core values and growth strategies, emphasizing the importance of innovation and effective organizational change for sustainable business success. The case study illustrates how DPS fosters a culture of continuous improvement and leadership development among employees.