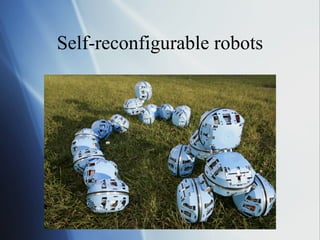

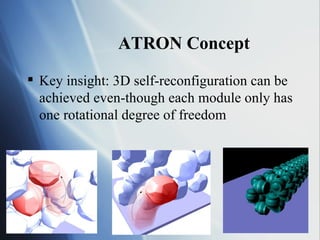

1) The document discusses the challenges and future directions of self-reconfigurable robots like the ATRON robot. It explores concepts like local control rules, gradients, scaffolds, and meta-modules.

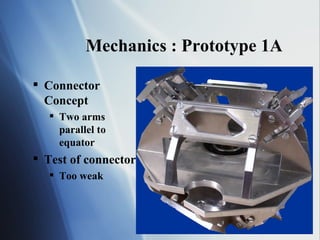

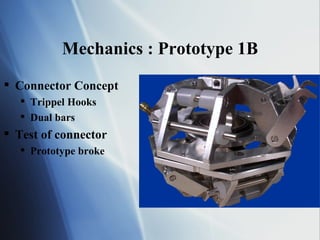

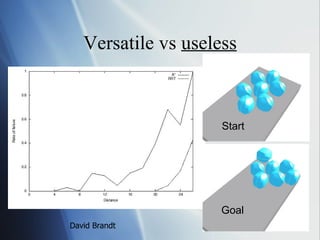

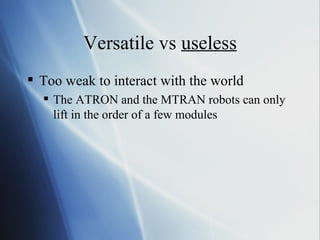

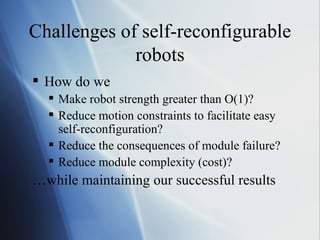

2) It describes the realities of self-reconfigurable robots as being fragile, useless, and expensive rather than robust, versatile, and cheap as originally envisioned. Challenges include weak strength, motion constraints, and high module complexity/cost.

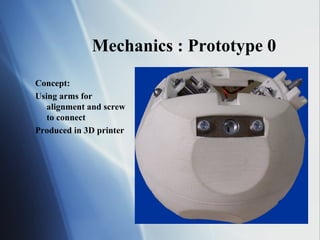

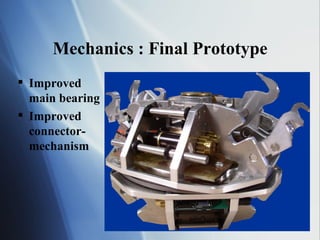

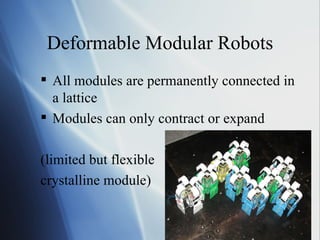

3) The author argues that new innovative hardware designs are needed to address these challenges, such as deformable modular robots that have permanently connected modules that can only contract or expand. This may help with strength, fault tolerance and reconfiguration but limits full self