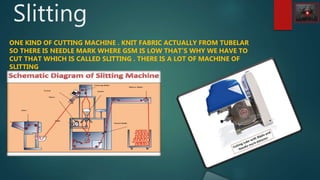

This presentation discusses the process of knit fabric dyeing. It is presented by MD. Mostafijur Rahman and Anan Wahid Riaz, students in the Textile Evening 41 Batch. The presentation covers the steps in knit fabric dyeing, which include grey fabric inspection, batching, scouring, bleaching, enzyme treatment, dyeing, hydro extractor/dewatering, slitting, stentering, compacting, and final inspection. The dyeing of knitted fabrics occurs through an exhaust method or batch-wise process, which is similar to yarn dyeing but has some differences in quality measurement.