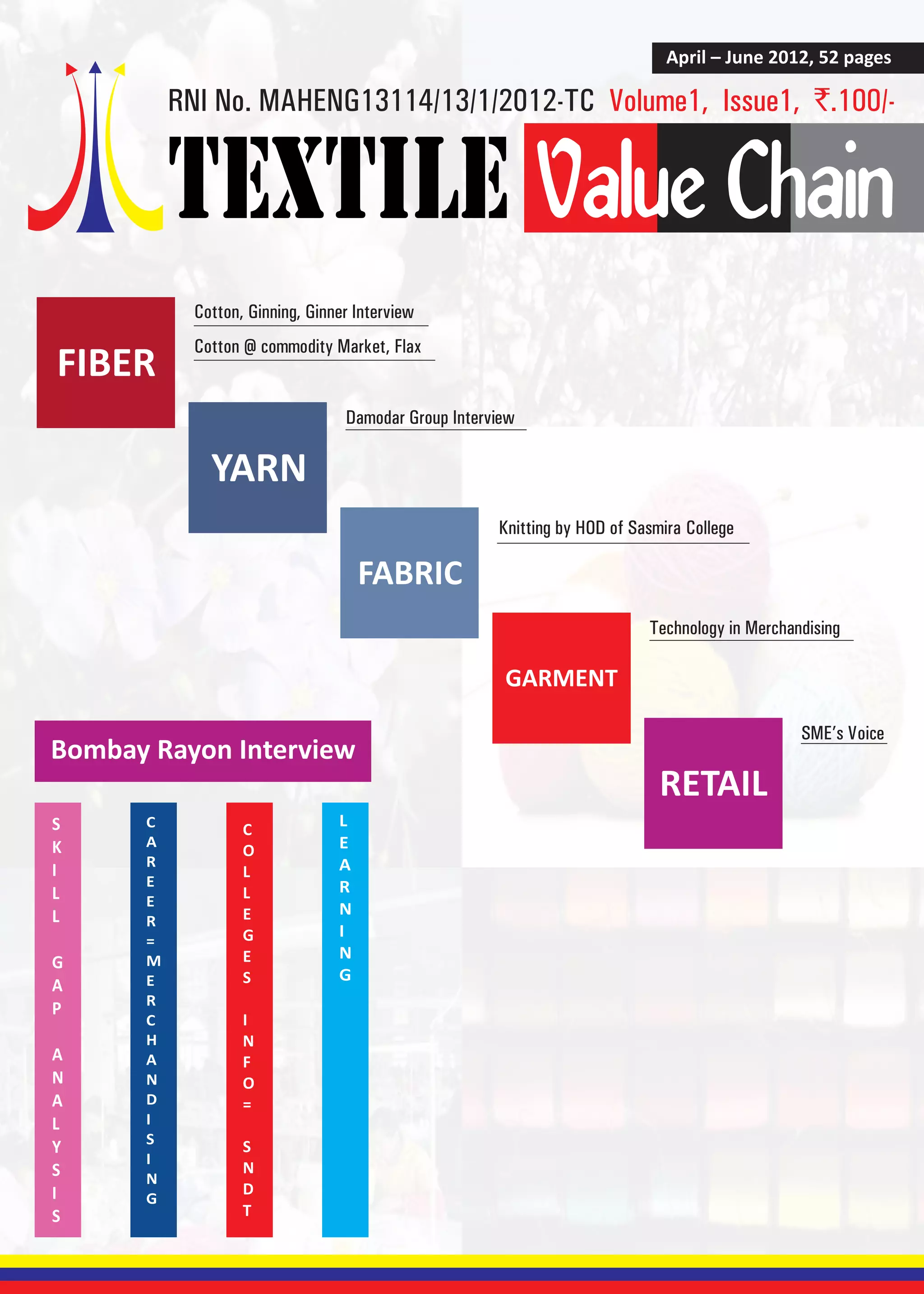

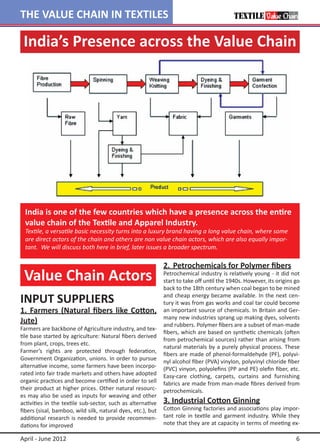

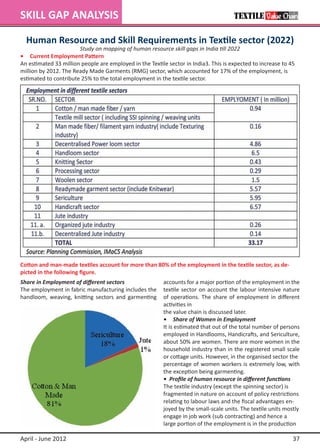

India has presence across the entire textile and apparel value chain, from input suppliers like farmers who grow natural fibers, to petrochemical companies who produce synthetic fibers, to industrial cotton ginning and small-scale spinning, weavers, textile manufacturers, and exporters. The value chain involves farmers, petrochemical suppliers, cotton and yarn producers, weavers, textile treatment companies, manufacturers, exporters, agents and shippers all adding value to the materials as they move from raw materials to finished products.