The global denim industry is expected to see market growth of 6.7% annually through 2029 after struggles during COVID. Denim jeans sales are projected to reach $88.1 billion by 2030 growing at 4.2% yearly. Rising incomes in developing nations are fueling spending on clothing including denim. While cotton is the primary material, sustainability efforts include using recycled fibers and alternatives like hemp which can be rotor spun into yarns for denim fabric production. India's denim exports fell 11% in 2016-17 but mills have since shown strong export growth, bringing stability to domestic markets as well.

![22 TVC | JULY 2022

A

bstract: Denim is the worldwide most

popular form used by all generations. Due to

very high volumes consumed daily, Brands

are deliberated to look for sustainability to save

the environment. Water, air and soil are the basic

elements in life. Conventional Indigo dyeing is a

lengthy process requiring pretreatment, washing,

battery of (dip, nip & air) indigo dyeing followed by

washing, drying and sizing beaming or batching. This

process uses huge amounts of resources like water,

chemicals, and energy. To achieve sustainability

over the conventional process, thorough study and

continual research has led to the evolution of ultra-

rapid dyeing technology.

This technology primarily focuses on the

concept of ultra-rapid indigo dyeing. Here the

substantivity of the indigo solution is tremendously

increasedbyachievingtherequiredphysico-chemical

parameters in an inert atmosphere. This enables the

super substantive leuco indigo to instantaneously

penetrate with a decreasing gradient in the core

of the fibre. Thus, giving darker shades at minimal

contact time. This evolved technology has been

successfully tested on cotton, bast and regenerated

yarns with certain preconditions. This technology

is being developed for achieving sustainability in

indigo dyeing. Here near zero water denim dyeing

has been made possible using the ultra-rapid indigo

dyeing technology.

1 Introduction

1.1 Sustainability is a social and ecological

process characterized by the pursuit of common

ideals [1] denoting the ability to continue to exist.

As ecologists believe that sustainability is achieved

through the balance of species and resources in

the environment, the consumption of available

resourcesmustnotbefasterthannaturallygenerated

resources in order to maintain this balance [2,3].

Sustainable development means striving to

balance local and global environments without

damaging the natural environment, so as to meet

the basic needs of mankind [4]. The result of rapid

industrialization has led to several toxic chemical

substances such as dye affecting the environment,

causing serious environmental pollution [5].

1.2 Denim is a unisex fashionable woven wear

for all generations. The global jeans business is

increasing in a drastic way because of its comfort-

ability, trend, and performance. Till today majority

of the denim production is done in the conventional

way using slasher, rope dyeing machines. There

have been advancements in these conventional

technologies for achieving specific goals like super

dark shades, multiple colour dyeing, precise e

controls for better workability, adaptability for

running various processes, also modifications to

achieve sustainability etc. A Sustainable future can

beachievediftheusageoflessenergy,lesschemicals

and less water is emphasised.

1.3 Denim Manufacturing in Brief:

Denim is a cotton warp-prominent twill fabric where

ULTRA RAPID INDIGO DYEING

[PA]

- A

PATH TO SUSTAINABILITY (ZLD)

COVER STORY

Director

Atharvaved Impex , Maharashtra India.

Head Operation

Director & COO

WFB Baird & Co India Pvt. Ltd.

Kochi, Kerala, India.

Bhushan Chaudhari

Jaydeep Umalkar

Pradeep Pillai](https://image.slidesharecdn.com/tvcjuly2022-231017111742-25c0f843/75/Textile-Value-Chain-July-2022-22-2048.jpg)

![23

TVC | JULY 2022

the weft passes below two or more warp threads[6]

.Ideal processes involving denim fabric production

are warping, dyeing, sizing, weaving, finishing, and

inspection. Denim is always warp dyed which takes

place after warping, unlike other woven fabrics.

Previously, all denim utilized ring-spun yarns, but

later on, ring yarns were replaced by OE yarns due

lesser price and rapid manufacturing of open-end

(OE) yarn, known as rotor spinning [7]. Yarns used

for warp of denim fabrics are typically 100% Cotton

in composition and comparatively coarser than

other woven fabrics.

Warping can be two types depending on the

dyeingmachine--BallwarpingorBeamwarping.This

warp loaded on creel passes through pretreatment

(wetting + scouring), 2 to 3 washings, 8 to 12 indigo

dyeing (dip + nip + air), 3 to 4 post washing, drying,

for sheet form sizing and beaming and for rope

batching in cans followed by rebeaming and sizing.

These sized beams are woven and finished as per

requirement.

1.4 Principle in Indigo dyeing:

Indigo, C I 1 the first colour discovered and

documented was dyed on textile materials in

wooden pots or vats in the early days and are water-

insoluble coloured compounds [8]. To make this dye

soluble, two steps of reaction are required. First,

reduction of vat dye into leuco vat dye by sodium

hydrosulphite. Second, neutralization of leuco vat

dye with caustic soda to give soluble sodium salt of

leuco vat dye. After dyeing, oxidation is needed to

reconvert the water-soluble sodium salt of leuco vat

dye into the water-insoluble original vat dye. Rinsing

at ambient temperatures in 2-3 rinsing baths after

oxidation is normally adequate to remove alkali and

unoxidized leuco compounds [6] .

1.5 Environmental challenges in Traditional Dyeing:

Traditional Indigo dyeing is a water-consuming

process. High amounts of water flow in wash boxes.

In Pre-wash boxes to rinse out caustic soda and other

auxiliariescompletelyfromthesubstrate.Continuous

rinsing also reduces the yarn temperature thereby

preparing the substrate for indigo dyeing at room

temperature. In Post-wash boxes to rinse out unfix

dyes and chemicals from dyed yarn surface. Huge

amounts of other resources like steam, compressed

air and power are also consumed in running the

traditional indigo dyeing machines which also adds

to the costs and various environmental factors. As

per the Greenpeace report, for producing two billion

jeans pants every year, it takes a total of 1.7 million

tons of chemicals and water consumption can reach

as much as 7,000 litres per one pair [9].

Consumption of large quantities of chemicals

and freshwater ends up in increased product cost

and larger volume of chemically loaded effluents;

particularly high pH and high quantity of sulfate salts

due to sodium dithionite followed by unfixed indigo

dye and their by products [10] .

1.6 Taking in consideration all the associated

drawbacks in traditional indigo dyeing, Ultra Rapid

Indigo dyeing technology is developed, achieving

the most required sustainability. In this evolved

dyeing method, the substantivity of the leuco

indigo is exponentially increased by maintaining the

required physico-chemical parameters in an inert

atmosphere. This enables the super substantive

leuco indigo to instantaneously penetrate with a

decreasing gradient in the core of the fibre. Thus,

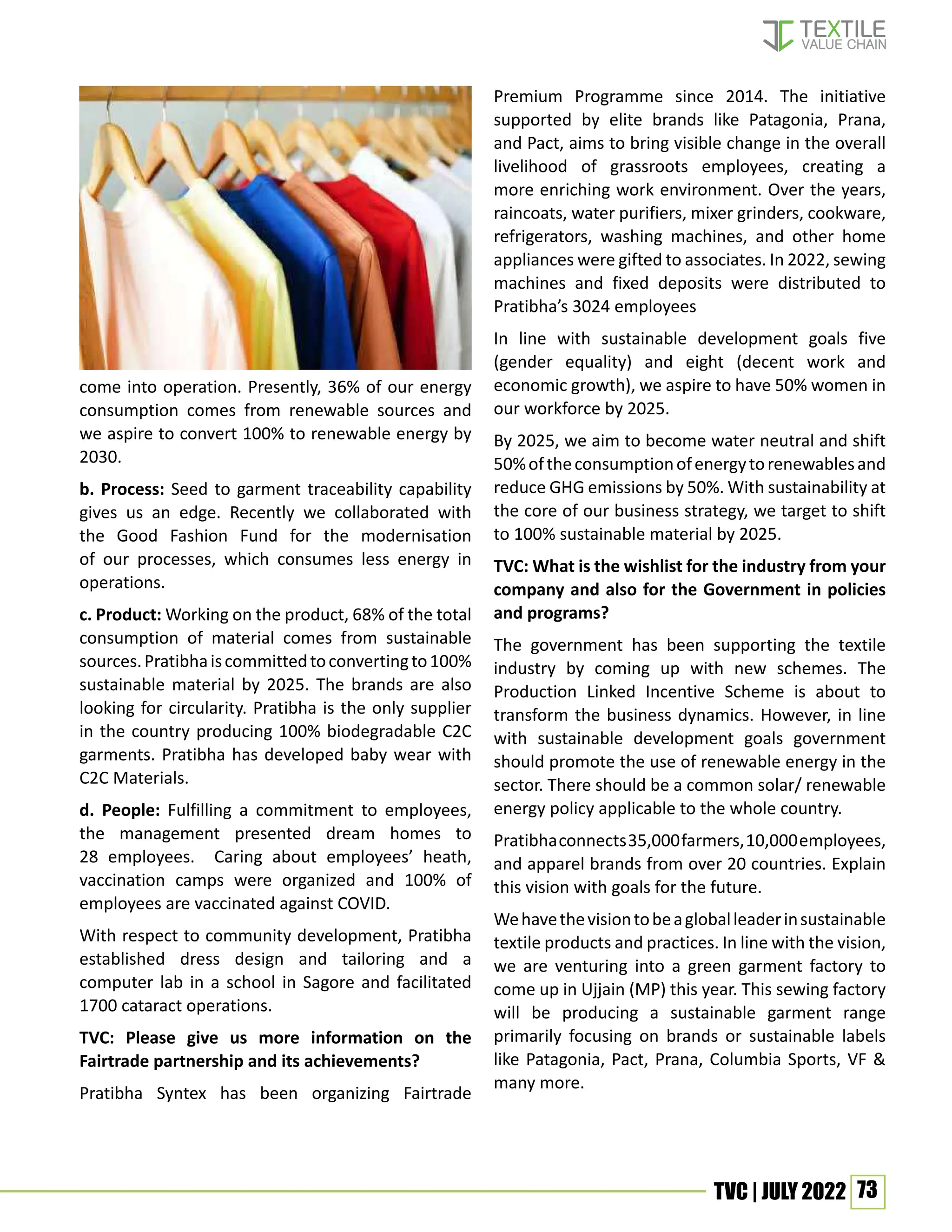

giving darker shades at minimal contact time (Fig1.).

This evolved technology has been successfully tested

on cotton, bast and regenerated yarns with certain

preconditions. Here near zero water indigo dyeing

has been made possible using the ultra-rapid (Flash)

indigo dyeing technology ultimately achieving

sustainable indigo dyeing.

Linen is very difficult to run on conventional

indigo dyeing machines due to many known

reasons. Hence in this dyeing experiment we have

chosen linen as the most sustainable textile fibre

to understand the benefits of this technology. Here

the basic properties of linen yarn before and after

dyeing have been compared. Using this technology

linen in cone form as well as sheet form can be dyed,

thus fulfilling the requirements of warp and weft.

2 Materials and Ultra Rapid dyeing Method :

2.1 Linen yarn.

2.2 Chemicals -Liquid indigo solution, water,

dispersing aid, alkali, reducing aid.](https://image.slidesharecdn.com/tvcjuly2022-231017111742-25c0f843/75/Textile-Value-Chain-July-2022-23-2048.jpg)

![24 TVC | JULY 2022

2.3 Ultra rapid Indigo dyeing[PA] method.

2.3.1 Preparation of Indigo Dyeing solution:

Measured quantity of pre-reduced indigo dye

solution is taken in a air sealed chamber having

99.9% pure nitrogen at a predetermined pressure, to

make up the volume blank vat (specially developed

chemical system, consisting of dispersing aid, alkali

and environmentally friendly reducing aid) is added

in measured quantity to get the desired Indigo

concentration.

2.3.2 The prepared dyeing solution is dosed

in the indigenously designed dyeing apparatus at

specified time, temperature and pressure making

the leuco dye highly substantive. The material to be

dyed is passed through the specially designed dyeing

apparatus where simultaneous application of this

highly substantive leuco dye is done in milliseconds.

Thus, enabling the super substantive leuco indigo

to instantaneously penetrate with a decreasing

gradient in the core of the fibre (Fig 1). Followed by

superficial extraction, drying and batching (Fig 2.).

In this CLP (i.e. Closed Loop Porcess) Total 2 litres of

dye liquor is used out of which colour pick up is 1.5

litres per kg of yarn which is eventually evaporated

in the process. Rest is dechannelized for reuse in the

continuous dyeing process. Thus, there is as such no

generation of any trade effluent during the ultra-

rapid indigo dyeing process. Here for drying the dyed

material both electric heating chambers and gas

fired chambers have been used ensuring near zero

emissions. This can be further extended to carbon

neutral system such as solar and wind energy.

2.3.3 This indigo dyed yarn is used in weaving

of the respective qualities either in warp and weft

for solids and only in weft for chambray.

2.3.4 After weaving the indigo dyed yarn fabric is

dye-fixed on the stenter and finished according to

the final product requirements.

2.4 Evaluation of Dyed Material

2.4.1 Determination of count of yarn using

Standard testing method of ASTM D1059

2.4.2 Determination of elongation in % and tensile

strength in RKM of linen yarn using standard testing

method of ASTM D2256

2.4.3 Determination of core pH using Standard

testing method AATCC 81, ISO 105 3071.

2.4.4 Determination of washing fastness using

Standard testing method AATCC 61 2A, ISO 105 CO6

A2S,B2S,C2S.

2.4.5 Determination of rubbing fastness using

Standard testing method AATCC 08, ISO 105 X 12.

3. Results and Discussion

From the data comparison [11] the following

Penetration of Indigo (Fig 1.)

Lower the

application

time Darker

the depth of

shade , better

wash down

effects

Application time (Milli Sec)

Shade Depth

Lower Higher

Darker Lighter

Higher the

application

time Lighter

the depth of

shade, flat

wash down

effects](https://image.slidesharecdn.com/tvcjuly2022-231017111742-25c0f843/75/Textile-Value-Chain-July-2022-24-2048.jpg)

![26 TVC | JULY 2022

combination of electric heated chambers and Lpg

fired chambers there by reducing the burden of

CO2 generated. In this case based on actual running

average consumption of electricity and LPG, the total

direct GHG emissions and indirect GHG emissions

are 1.438 KgCO2/Kg of ultra-rapid indigo dyed yarn.

4. Conclusion

The main aim of using the ultra-rapid indigo

dyeing technology is to achieve sustainability by

reducing water usage, using less energy and less

harmful chemicals in getting the regular Indigo dyed

yarn as per the conventional process.

From the above results in comparison with the

standards derived from conventional process we can

conclude that the properties of Ultra rapid Indigo

dyed yarn under study are up to the mark and have

no hurdles in being readily absorbed in the regular

production.

Water trajectory – Approximately 150 litres of

waterperkgfabricisutilisedinatypicalindigodyeing

process [9]. By using the Ultra Rapid Indigo Dyeing

technology this utilisation can be brought to 2 litres

of water per kg of yarn i.e. in corresponding fabric

this will translate to 1 litre per kg of denim fabric

where warp is indigo dyed and weft is plain white.

This technology enables to use only approx. 1% of

water compared with conventional indigo dyeing

process. Since all the dye liquor being consumed

and reused there is no effluent generated at source.

Hence, saving in treatment of wastewater, saving in

energy, and savings in raw material and chemicals in

indigo dyeing and subsequent process.

New generation customers are very much

aware of environmental hazards, sustainability,

sustainable supply chain, and corporate social

responsibility. That is why retailers are now turning

towards sustainable apparel production. So, an eco-

friendly ultra-rapid indigo dyeing process can be a

good concept for the sustainable denim business.

References

[1] Wandemberg, J.C. Sustainable by Design;

CreateSpace Independent Publishing Platform:

Seattle, WA, USA, 2015; ISBN 978-1516901784.

[2] Chaudhary, S.; Mehra, R.; Head, E.E. Role of

Globalized Approach for Sustainability Development

In Human Life. People Int. J. Soc. Sci. 2018, 4, 1497–

1507. [CrossRef]

[3] Davies, N. Using Bact eria to Decolourize Textile

Wastewater. AATCC Rev. 2017, 17, 32–37. [CrossRef]

[4] Robert, K.W.; Parris, T.M.; Leiserowitz, A.A. What

is Sustainable Development? Goals, Indicators,

Values, and Practice. Environ. Sci. Policy Sustain.

Dev. 2005, 47, 8–21. [CrossRef]

[5] Dhanjal, N.I.K.; Mittu, B.; Chauhan, A.; Gupta, S.

Biodegradation of Textile Dyes Using Fungal Isolates.

J. Environ. Sci. Technol.2013, 6, 99–105. [CrossRef]

[6] E. Csanák, “Denim Fitting & Finishing : Challenges

on High-Quality,” in International Joint Conference

on Environmental and Light Industry Technologies,

2015, no. November, p. 10.

[7] M. G. Uddin, “Indigo Ring Dyeing of Cotton Warp

Yarns for Denim Fabric,” Chem. Mater. Eng., vol. 2,

no. 7, pp. 149–154, 2014.

[8] V. A. Shenai, Chemistry of Dyes and Principles of

Dyeing, Third. Mumbai: Sevak Publications, 1997.

[9] B. Jiby., “The Indian Denim Industry In a Market

Driven Environment,” Int. J. Adv. Res., vol. 5, no. 6,

pp. 2088–2095, Jun. 2017.

[10] S. Meraj, A. Qayoom, and A. S. N., “Effective

Process Optimization of Indigo Rope Dyeing : A

Case Study,” J. New Technol. Mater., vol. 6, no. 2, pp.

33–37, 2016.

[11] Actual testing DATA as received from WFB Baird

& Company Pvt. Ltd. Kochi, Kerala, India.

[12] PA - Patent Applied.](https://image.slidesharecdn.com/tvcjuly2022-231017111742-25c0f843/75/Textile-Value-Chain-July-2022-26-2048.jpg)

![42 TVC | JULY 2022

Abstract

Currently, all denim is made out of cotton

fibres or blends with high cotton content using a twill

weave. However, denim has a poor environmental

balance sheet, which starts with the planting of the

cotton needed for it and continues with the high

water consumption and use of chemicals.Therefore,

in order to reduce the emissions caused by these,

possible alternatives are being sought. A possible

alternative, which is considered in this paper, is the

use of hemp fibres to substitute cotton. Various

aspects such as the cultivability, producibility and

processability of hemp yarns are considered here.

The results show that hemp can be grown and

processed locally very well.Unfortunately,some

further research and development is required for

pure hemp fibres processing on a rotor spinning

machine in a process-stable manner. Based on

this, recommendations are given on how rotor

spinning machines can be adapted constructively to

overcome this deficit.

Introduction

The role of climate change and thus a

sustainable world is becoming increasingly

important. In 2012, the members of the United

Nations set 17 goals to create a more socially and

ecologically sustainable world. One of these goals

is “Responsible Consumption and Production”.

Relevant here are not only environmentally friendly

end products, but transparent and sustainable

processes throughout the entire product creation

process. [UN15] Natural fibres are thus becoming

increasinglyimportantbothintheclothingsectorand

for technical textiles. Up to now, cotton has made up

by far the largest share of natural yarns produced. In

jeans production in particular, it becomes clear how

much need there is for improvement with regard to

sustainability aspects. Not only the very high water

consumption, the use of chemicals for cultivation

and dyeing but also the long supply chains with their

ecological impacts [Opp14].

Therefore, this paper focuses on the

consideration of more sustainable alternatives in

jeans production. For this purpose, the usability

of hemp is looked at on different levels. First, the

properties of the fibres themselves are discussed

and later the technical feasibility of producing yarns.

For this purpose, the production with the help of

the rotor spinning process is examined more closely.

Rotor spinning was chosen in a project for producing

technical textiles because of its fabric resistance and

yarn propertiesas well as the productivity compared

to ring spinning. It turned out, that with minor

developments and changes in the rotor spinning

machine, a fine Ne 20 yarn was producible which

is suitable for denim use as well. Rotor spinning

without any additional changes however is currently

not yet possible with 100% hemp but only with the

addition of cotton. Mostly, between 50 to 70 %of

cotton are added. Based on this, target values are

defined that should enable the production of hemp

yarns. Finally, statements are made about the extent

to which production is possible with the help of

changes to construction-specific aspects.

review paper

Further improvements in rotor

spinning and denim out of Hemp

Justin Kuehn Lukas Lechthaler Thomas Gries

Maria Shirov_

Michna

Seyit Halac

( Institut für Textiltechnik of RWTH Aachen University)

Kira Hirschberger](https://image.slidesharecdn.com/tvcjuly2022-231017111742-25c0f843/75/Textile-Value-Chain-July-2022-42-2048.jpg)

![43

TVC | JULY 2022

State of the art

Fibres

As mentioned, jeans production is mainly

based on cotton. In terms of sustainability, however,

cotton has disadvantages compared to other

natural fibres. The plant is demanding, it needs

warm temperatures without sudden temperature

transitions. At the same time, cotton plants have a

high water requirement of 1214 l per kg in average

[BCE19]. Cultivation mainly takes place in tropical

and subtropical areas [Hor20]. Hemp, on the other

hand, can be grown locally everywhere, which is

particularly attractive for the European market. This

means that long, CO2-intensive routes, for example,

can be avoided.Additionally, cotonised hemp fibres

have fineness, softness and spinning properties that

are close to those of cotton. Here, important factors

in fibre preparation are retting and subsequent

mechanical preparation.

As a domestic alternative, hemp is accordingly

gaining increasing attention in Europe. The needs of

the hemp plant are predestined for the European

region. Moreover, hemp is much less demanding to

grow than cotton. The plant is very robust against

pests, which is why neither pesticides nor herbicides

are needed. Furthermore, hemp in general requires

no artificial irrigation. With sufficiently good

processing,hempfibresofferapplicationpossibilities

in various textile sectors. High absorbency and good

thermal conductivity make hemp interesting for the

clothing sector and thus also for jeans production.

This shall lead to a cooling effect while wearing.

The high fineness-related strength namely offers

opportunities for home textiles as well as technical

textiles. Due to their weather resistance, the fibres

can also be used in areas where synthetic fibres

currently dominate. [CGP+08, KRM20]

Since jeans are not only made of cotton but

also of synthetic fibres, this is another argument

for the use of hemp in the production of textiles. In

addition, hemp has other advantages, such as the

fact that it is very prolific and covers all weeds, and

that it absorbs a lot of CO2 as an C3 crop. Thus, the

sustainability aspect is once again emphasised, as

the plant does not only save CO2 due to logistical

circumstances, but because of characteristics such

as water consumption and CO2 absorption. [Nov01]

Production

The use of hemp fibres as an ecological and

cheap alternative in the textile industry is currently

facing two primary challenges. On the one hand, the

processing methods used in the industry for hemp

fibres involve ecologically questionable processes

and are too expensive in the given quantities for

successful marketing of the material, and on the

other hand, the spinning processes used for hemp

fibres are not competitive due to low product

diversity and number of buyers.

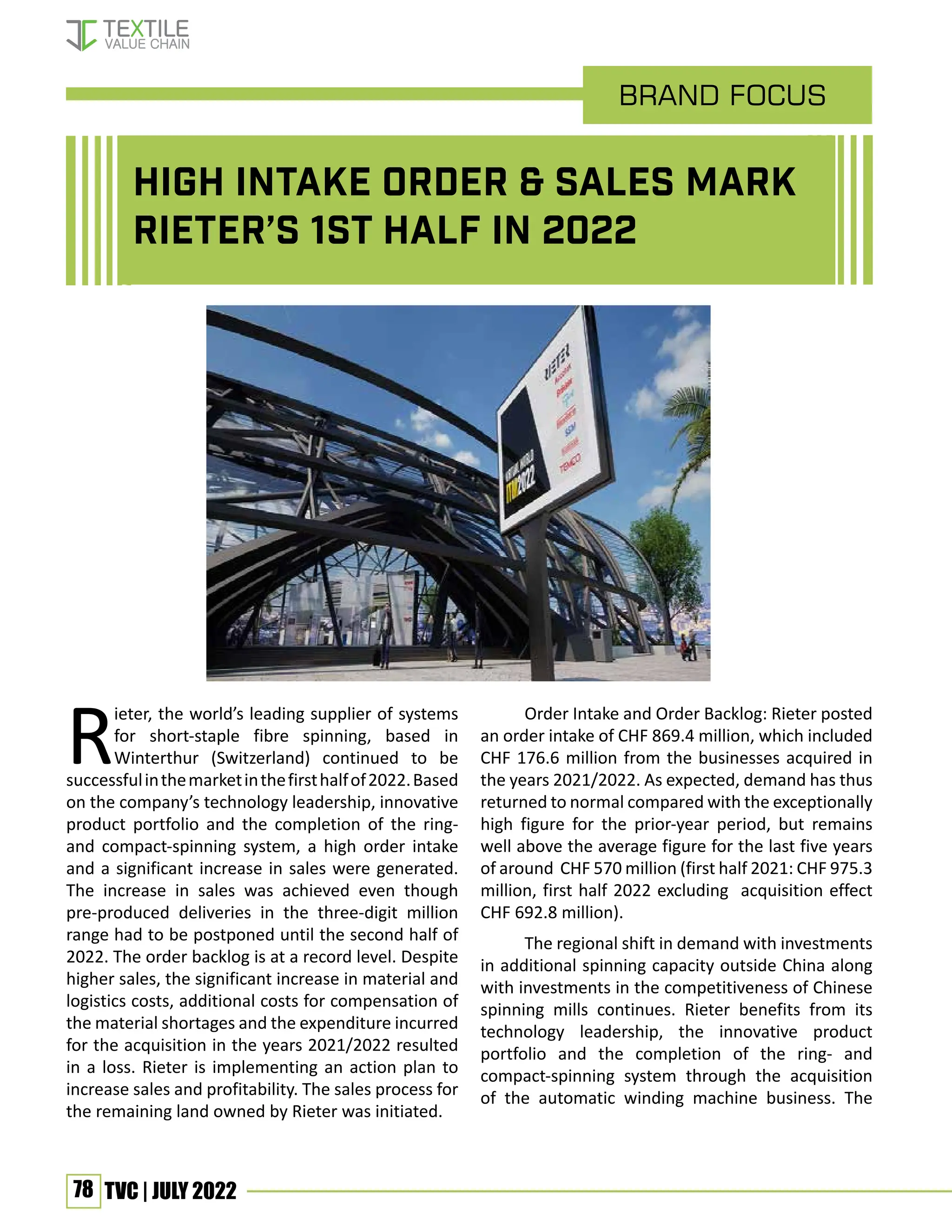

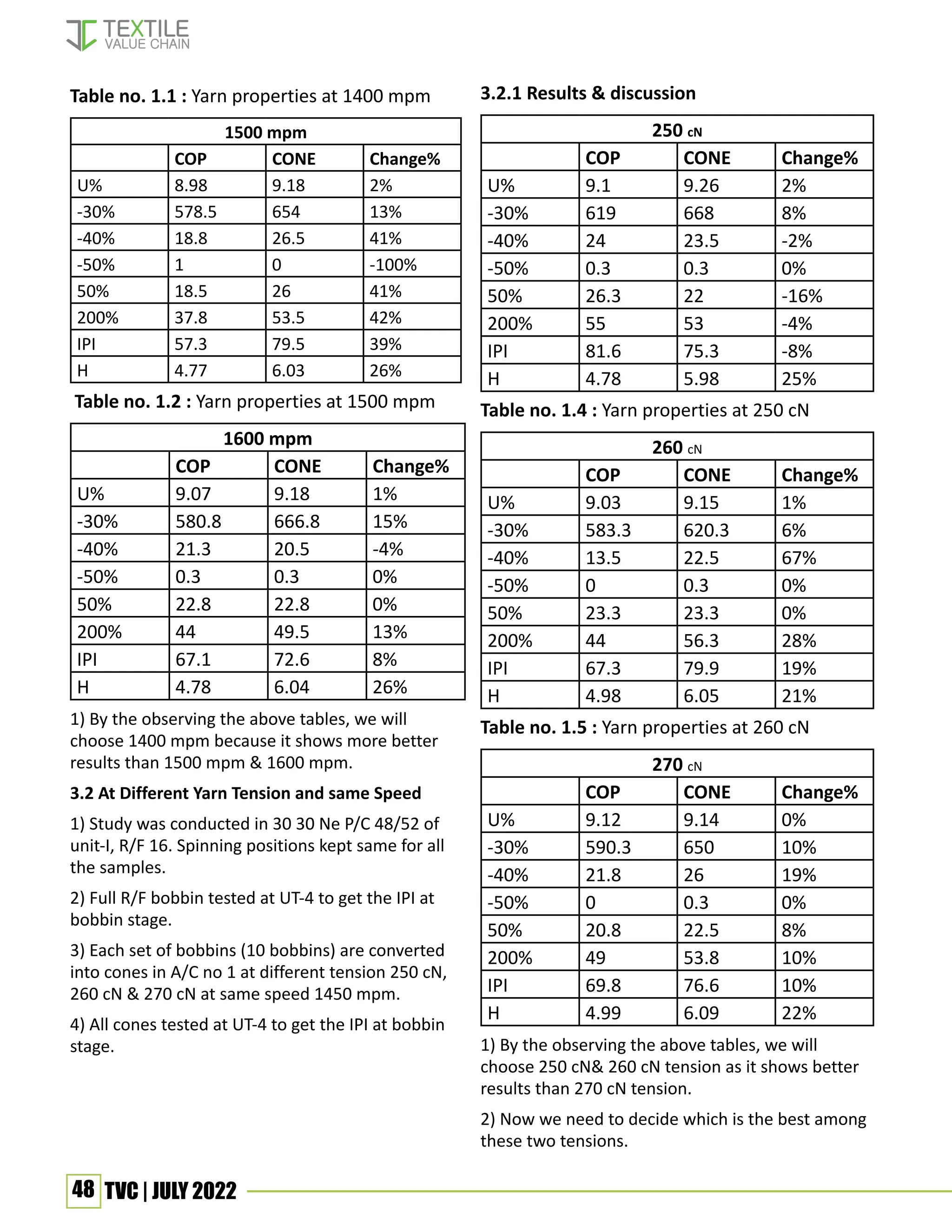

The rotor spinning (cf. Figure 1) process is

adopted for the production of hemp yarns. However,

the processing of hemp is made more difficult by

the physical properties of the fibres, as on the one

hand they have a high bending stiffness compared to

cotton, which makes the initiation of the twist more

difficult, and on the other hand dust is produced

during processing, which is deposited in the rotor

groove and strongly influences the spinning stability

in the long run.

Figure 1: SpinBox SE10 of Suessen GmbH;

open cover (left) and closed cover (right)](https://image.slidesharecdn.com/tvcjuly2022-231017111742-25c0f843/75/Textile-Value-Chain-July-2022-43-2048.jpg)

![44 TVC | JULY 2022

Therearemodernapproachesforacompetitive

use of hemp fibres. In principle, various alternative

processes can be used for fibre digestion. The fibres

can be digested mechanically, physically, chemically-

physically or microbially. In the European industry,

ultrasonic digestion and steam pressure digestion

are currently used. The number of short fibre lines

for the digestion of hemp fibres is low due to the

lack of further processing options.

In a cross-border project of Germany and

the Netherlands “Regional hemp chain for textile

production”, a jeans fabric could be produced with

hemp fibres broken down by steam pressure. The

yarn was spun on slightly modified rotor spinning

machines. However, 50 % cotton was added for

better processability. The aim here, however, is to

completely dispense with the addition of cotton and

to enable production with hemp fibres only.

Implementation

In order to enable production using the rotor

spinning process, requirements have been identified

which must be fulfilled. On the one hand, this is the

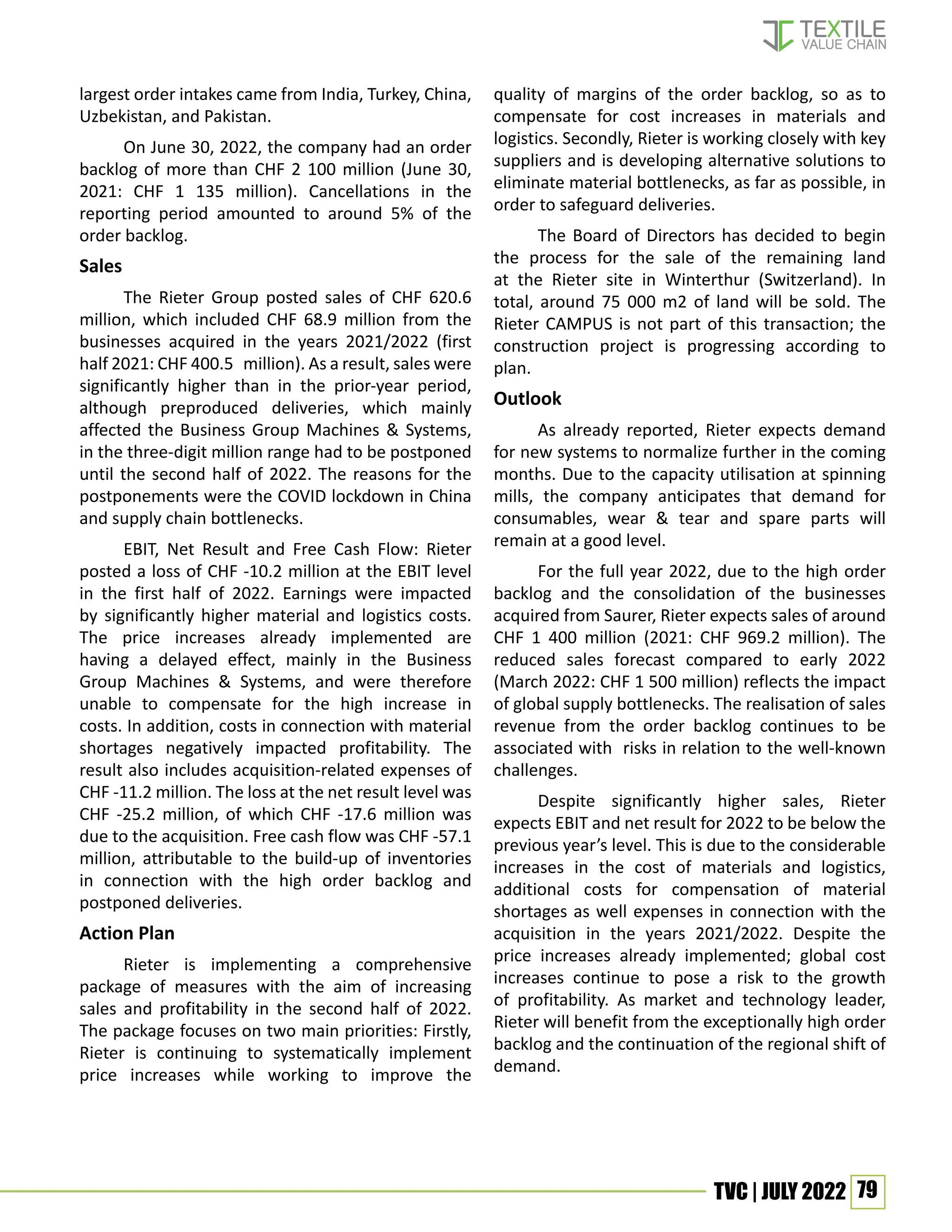

removal of dirt (cf. Figure 2) while keeping as many

fibres as possible in the opening rollerof the system.

Two possibilities have been identified for this:

1. The existing dirt separation can be improved

2. The system can be supplemented with an

alternative dirt separation mechanism

Figure 2: Sketch of dust removal in a rotor

spinning box, based on [Tro95]

Another possibility is not to remove the dirt,

but to directly combat the cause of the dirt and to

contain the formation of it.

The following principle solutions were

identified for these two possibilities:

a) Radial suction of the opening roller

b) Axial suction of the opening roller

c) Rotor equipped with dirt separation openings

d) Cross-flow in the combing-out area (direction of

action 1)

e) Cross-flow in the combing-out area (direction of

action 2)

For the technical and economic comparison,

the following criteria are used for evaluation:

a) Acquisition costs

b) Operating costs

c) Conversion costs

d) Expenditure for change of material

e) Restrictions on the choice of spinning media

Results

When looking at the potential of hemp fibres

themselves, it becomes clear that they are a very

good alternative to cotton in terms of sustainability

aspects. Hemp yarn production, on the other hand,

has shown that there are still some problems to

overcome.

Results show, that that for the considered

principle solutions for rotor spinning, due to

the additional costs for production changes and

possibly more often lot changes, if the market does

not rise significantly by higher offers.Also, the high

conversion effort for automated systems, extraction

is the worse alternative compared to the rotor

concept for industry. If the rotor concept becomes

established in industry, the acquisition costs will also

decrease and the number of available rotor designs

will increase. In this case, the rotor concept would

also score better in terms of flexibility and would

also be a good option for contract spinning mills.

During the production of hemp yarn on

commercially available rotor spinning machines,

however, high fibre damage and dust formation

occur. This is due to the high brittleness of the hemp

fibres compared to cotton in connection with the](https://image.slidesharecdn.com/tvcjuly2022-231017111742-25c0f843/75/Textile-Value-Chain-July-2022-44-2048.jpg)

![45

TVC | JULY 2022

mechanical stress during the opening process, which

is usual for the rotor spinning process. The resulting

dirt deposits in the rotor groove impair spinning

stability in the long run. Based on this, possibilities

were worked out to reduce these dust deposits

constructively. In doing so, the improvement of the

current dirt separation as well as a potential addition

to it were examined. It was also investigated whether

the formation of dirt can be reduced by constructive

measures. The aim here is a stable spinning process

for pure hemp yarn.

Results show, that at the present time, it is

not possible to evaluate the principles in a way that

adequately reflects reality. Above all, the fulfilment

of the function and the strength of the undesirable

influences on the spinning process cannot be

determined with certainty. The respective influences

have not yet been sufficiently investigated for the

processing of hemp in order to find a systematic

solution for the constructive containment of fibre

damage.

Conclusion

The results show that hemp in general has a

high potential to enable a more sustainable denim

production. Hemp fibres have many advantages

over cotton in terms of sustainability.The advantages

of hemp over cotton are manifold. On the one

hand, the fact that hemp can be grown locally

everywhere speaks for its use. This would eliminate

long transport routes and save a significant amount

of CO2. In addition, hemp requires significantly less

water for cultivation than cotton and significantly

smaller amounts of pesticides are used. Last but not

least, hemp absorbs significantly more CO2, which is

another important aspect of sustainability.

In order to be able to use this advantages

of hemp over cotton as much as possible in the

future and to validate the assumptions made in

this paper regarding the production of hemp yarns,

more empirical trials with hemp fibres should be

carried out. In doing so, the effects of the spinning

settings on the fibre damage must be checked. This

would realise large savings of CO2 in the production

of denim in the future and thus enable a more

sustainable textile production all over the globe.

Acknowledgement:

The research project ZF4558957CJ9

(SustainPol) of AiFProjekt GmbH, Berlin, is funded

within the framework of the Central Innovation

Programme for SMEs (ZIM) by the Federal Ministry

for Economic Affairs and Climate Action (BMWK)

based on a resolution of the German parliament.

References

[BCE19] Bremen Cotton Exchange

Cotton: No thirsty plant

Press release March 22nd 2019

[CGP+08] Carus, M.; Gahle, C.; Pendarovski, C.;

Vogt, D.; Ortmann, S.;

Grotenhermen, F.; Breuer, T.;

Schmidt, C.:

Gülzower Fachgespräche,

Volume 26

Hürth: nova-Institut GmbH, 2008

[Hor20] Hortmeyer, E.:

Top 10 Cotton Producing Countries

in the World, Discover Natural Fibres

Initiative, 2020

URL: https://dnfi.org/cotton/top-10-

cotton-producing-countries-in-the-

world_4785/, access on 17.05.2021

[KRM20] Kozłowski, R. M.; Mackiewicz-

Talarczyk, M.:Handbook of Natural

Fibres, Band 2, 2. Edition,

Duxford, United Kingdom:

Woodhead Publishing, 2020

[Nov01] Nova-Institut (Ed.)

Das kleineHanf-Lexikon

Die Werkstatt (Göttingen), 2001

[Opp14] Oppel A.:

Der Anbau der Baumwolle in

Abhängigkeit von Klima und

` Boden geographische Zeitschrift

20 (1914), H. 5, S. 241-257

[Tro95] Trommer, G.: Rotorspinnen,

Frankfurt am Main: Deutscher

Fachverlag, 1995

[UN15] United Nations: Transforming

our World: The 2030 Agenda

für Sustainable Development,

UN, 2015](https://image.slidesharecdn.com/tvcjuly2022-231017111742-25c0f843/75/Textile-Value-Chain-July-2022-45-2048.jpg)

![63

TVC | JULY 2022

Indian silk is a not so happy story, and corrections

are thereon, says Munish Tyagi, a global textile

leader & international textile consultant,

Nuovatex Global Textile Outlook, under the heading

Ground Diagnostics &Way Out On silk Industry’s

`Degrowth `In India.

QN: What are the possible reasons for sharp

decline (-53%) of RMG silk exports from a high of

US$ 244 million in 2015-16 to a low US$114 million

in 2021-22?

Ans:The key factors to be understood, are mainly:

A] decreasing use of silk in high value Furnishing &

bedcover materials in importing countries.

B] Decline of India’s silk carpet exporting industry

based in Kashmir and eastern UP,

C]increased use of cheaper and same feel and `light

in feel ` materials like Viscose, micro-Polyesters

D] overall lower quality and much higher yardage

cost of silks vis a vis above MMF fibre textiles.

QN:Did any competitor country/ countries eat up

India’s share in the referred period? If yes, in which

markets and what were the reasons that enabled

those countries to eat India’s share in silk exports?

Ans:Yes, there been an emergence of competition

from countries like China, the global market leader;

and also, from newly emerging silk producers like

Thailand, Laos, Vietnam. Korea and Uzbekistan and,

Iran in case of silk carpet exports. Their Mulberry

silks are of higher quality too.

QN: Were there any specific domestic reasons that

led to India’s decline in RMG silk exports (e.g.,

compliance rejections, price uncompetitiveness,

etc.)?

Ans:There have been mainly the following negative

drivers to impact growth of domestic silk:

A] much reduced consumption of silk in the declining

demand for traditional silkwear like Sarees,dupattas

as and their replacement by more comfortable and

cheaper MMF fabrics,

B] increasing preference by the younger population

for ` easy to use and maintain` MMF fabrics

likepolyesters and viscose filament esp. with

ever increasing support of Digital Printing in the

Suratpolyester sarees sector. Young Customers do

not find silk to be glorified or comfortable.

QN: Is there any possibility of apparels and home

textiles made from cheap silk fibre substitutes

disrupting the market positioning of India?

Ans: Already there has been disruption to silk

based markets by the cheaper fibre substitutes like

the Viscose, polyesters and bamboo fabrics;and

also, more comfortable to wear fabrics of cotton

dominated blends like cotton khadi, cotton-viscose,

cotton-polyester, cotton-linen and cotton-bamboo

etc. whereby the % ratio of the any component can

be varied in the blend yarn spinning;for example

linen and viscose in blend with cottons; and

definitely polyester fabrics. A new challenge from

cotton hemp blends coming in too as also advent of

new soft fibres like that from milk protein etc.

QN: Is better manufacturing technology in silk

sector giving the competitors enabling them to

edge past India?

Ans: India’s silk industry has been limited in its

growth, productivity and quality of its output owing

toboth the nature of Indian silks, the continued

use of outdated/ high cost/low output technology

esp, in the key activity areas like silk Reeling and its

twisting and weaving for fabrics with low level of

productivity, yield and quality control right from the

cocoon stage to the eventual fabric stage.What India

requires is large scale and higher quality silk reeling

silk outlook

Indian silk is a Not so Happy

Story!](https://image.slidesharecdn.com/tvcjuly2022-231017111742-25c0f843/75/Textile-Value-Chain-July-2022-63-2048.jpg)

![64 TVC | JULY 2022

units which can produce quality of silk acceptable

to newer shuttleless Rapier weaving looms. Also, its

much late but much desirable that Knitting industry

takes up production of high value knit fabrics with

Italy as role model

QN: The growth rate of silk exports from India

between 2015-16 to 2021-22 to countries like UK

(-55%), France (-32%), Germany (-19%), Italy (-42%)

and Canada (-40%) have shrunk significantly. What

are the possible reasons for the same?

Ans:The principal reasons for this serious decline in

exports to the UK/France Europe/other countries in

the EUregion are mainly on account of:

A] better quality of silk products and competitive

prices from countries like Uzbek, China, others and

B] increasing use of polyester and viscose MMF

fabrics, which has been replacing silk, and also

C] tariff and non-tariff concessions available to

competitors like Vietnam, Cambodia, Myanmar,

others

QN:Tassar silk production during the year 2021-22

was less by 46% as compared to previous year.

Ans: India produces local coarser variety of silks like

Tassar, Eri and Muga, mostly in the eastern States of

Bihar, Jharkhand and Assam etc. These are mostly

for end uses in non-apparel or non-wearable end

useslike mainly for use in furnishings and upholstery

for their roughage. The apparel demand for these

is minimal and has not been developed due to No

serious work done on blending these with MMF

fibres.This segment has got impacted vis a vis better

design capability and cheaper price from polyester

and finerviscose fabrics which are more amenable to

accept faster Digital Print design in the `fast fashion`

market, as also dobby and jacquard based designs

in every emerging home textiles and furnishing

segments. The only price disruption been in lower

quality products using the waste or spun silk,

andthere is a clear and need to setup yarn spinning

mills for spun yarns, and adj.to such silk clusters.

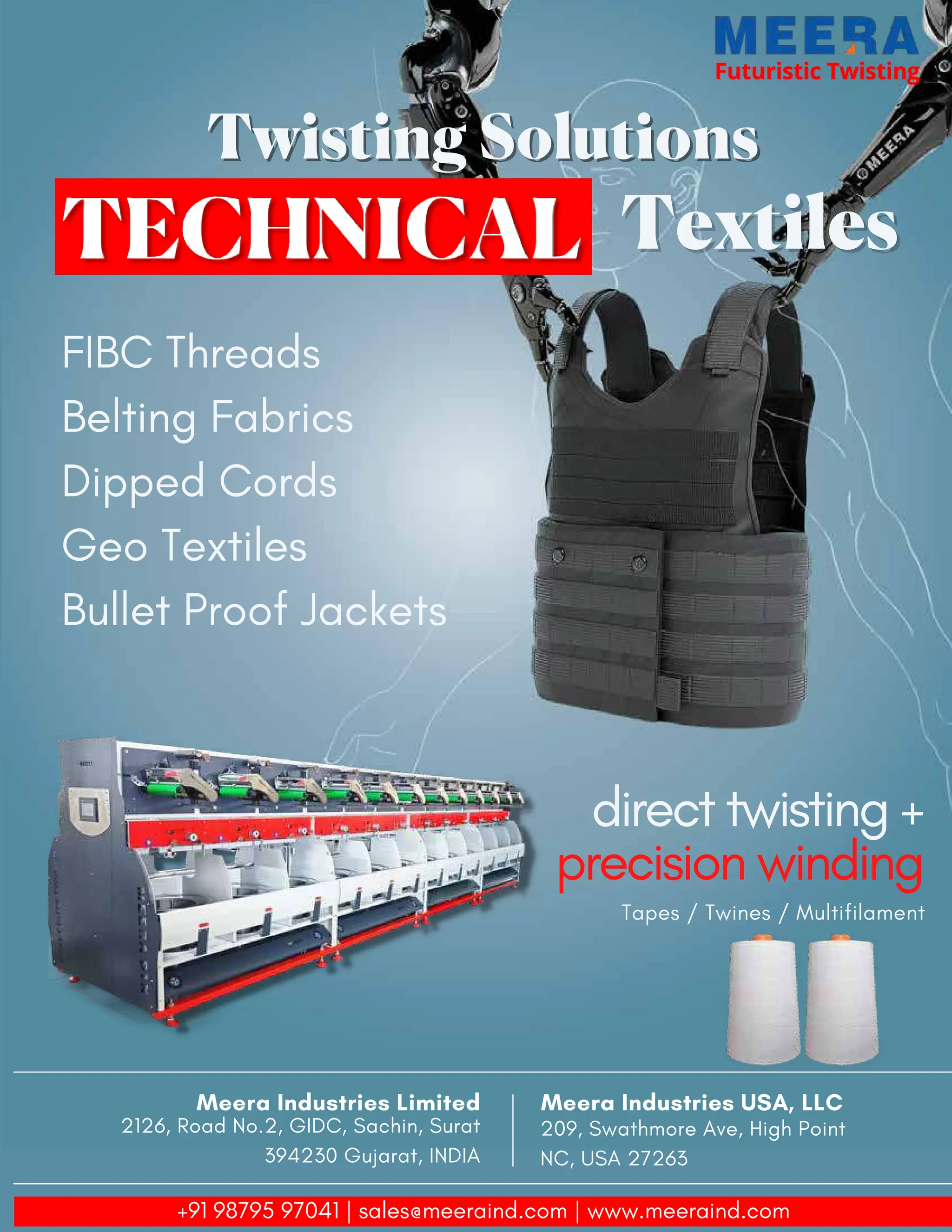

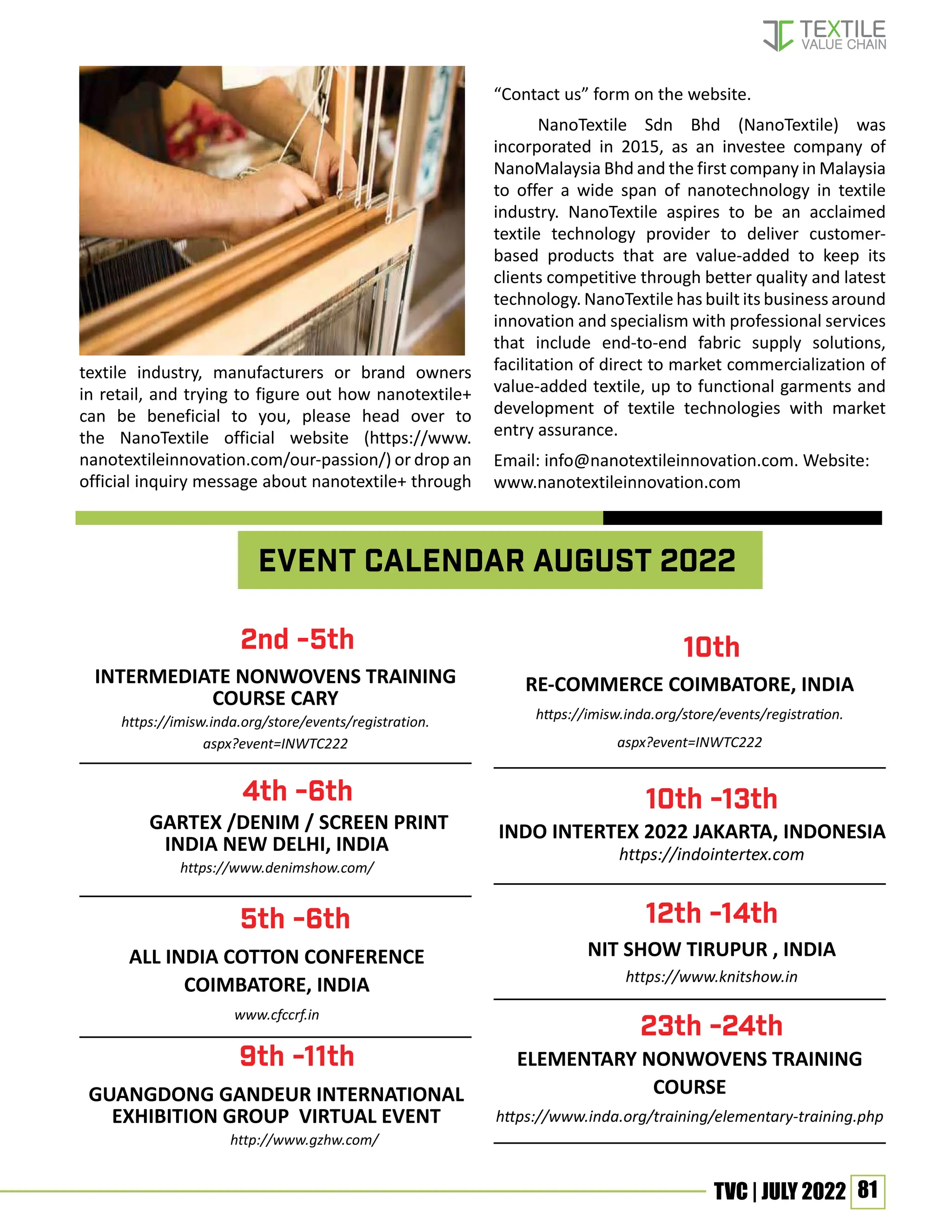

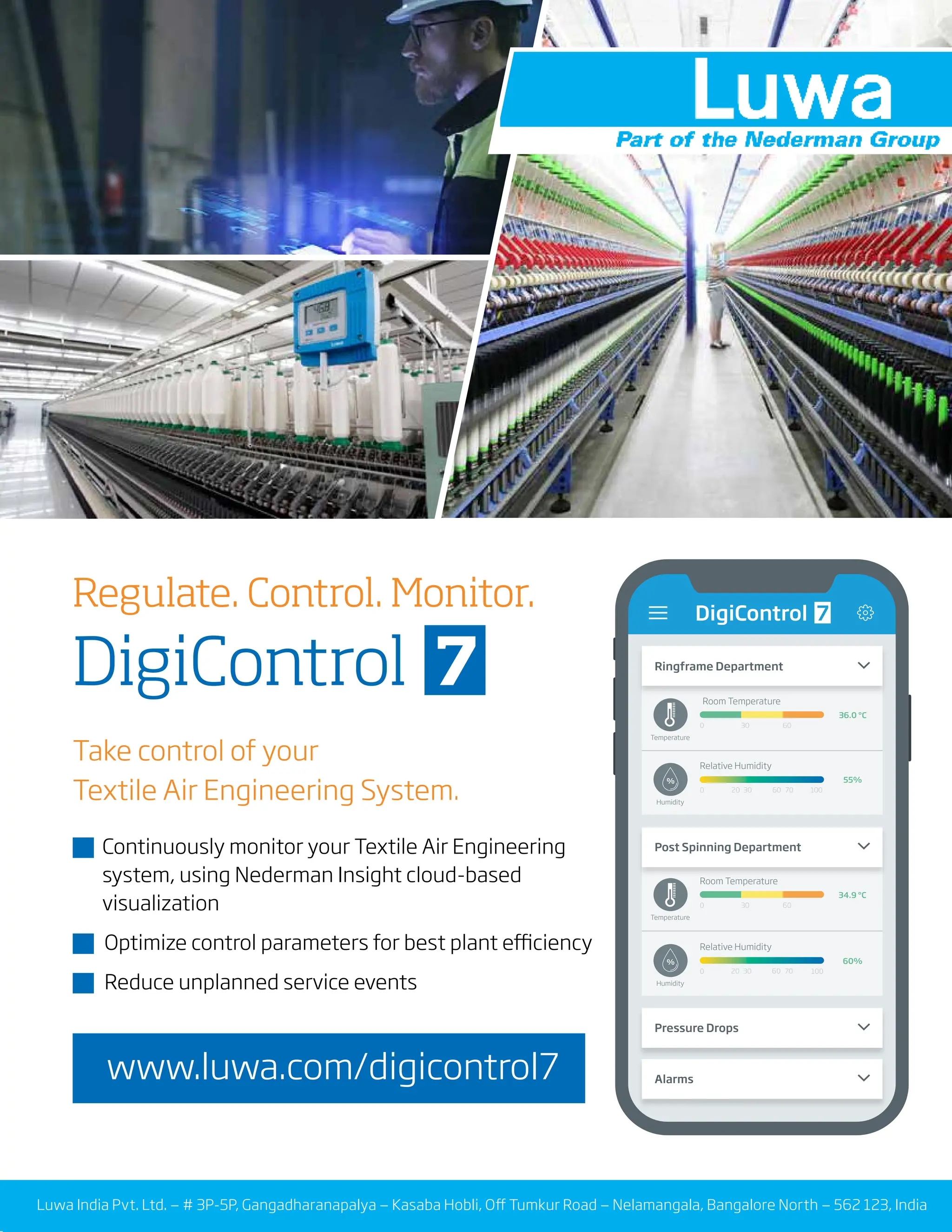

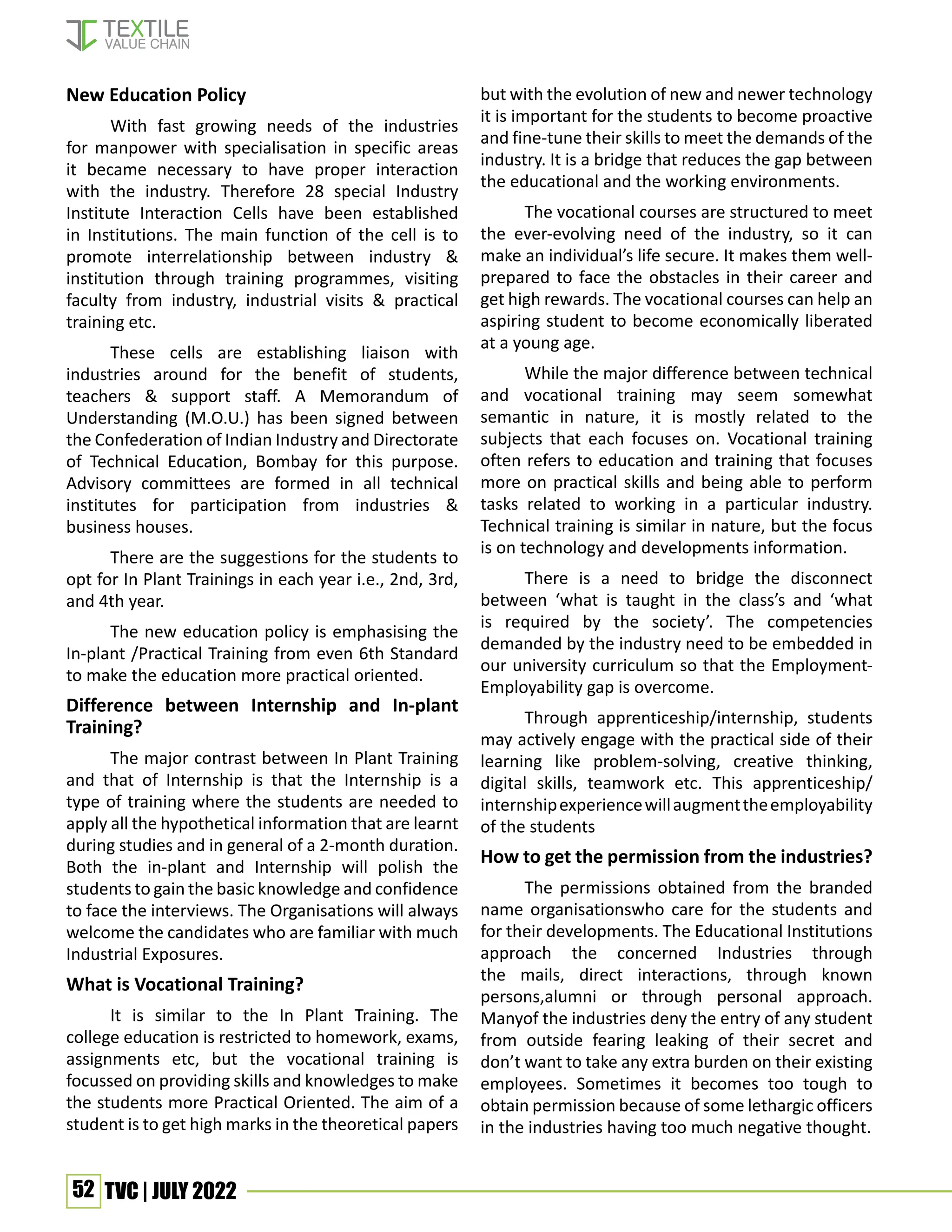

Unit: USD Millions

Source: Ministry of Commerce and Industry

5.42

22.84

49.34

95.56

93.68

23.74

22.23

89.93

133.75

48.73

66.46

116.43

286.2

388.22

35.65

22.61

33.98

121.09

196.48

62.26

MA Y 2021 (F ) MA Y 2022 (F ) JA N-

MA Y 2021 (F )

JA N-

MA Y 2022 (F )

% GROW T H

NATURAL FIBRE IMPORT

SILK

WOOL, FINE OR COARSE ANIMAL HAIR, HORSEHAIR YARN AND WOVEN FABRIC.

COTTON.

OTHER VEGETABLE TEXTILE FIBRES; PAPER YARN AND WOVEN FABRICS OF PAPER

YARN.

May 2021 (F)

May

2022 (F)

Jan-May

2021 (F)

Jan-May

2022 (F)

%Growth

5.42 22.84 49.34 95.56 93.68

23.74 22.23 89.93 133.75 48.73

66.46 116.43 286.2 388.22 35.65

22.61 33.98 121.09 196.48 62.26

IMPORT

May 2021 (F)

May

2022 (F)

Jan-May

2021 (F)

Jan-May

2022 (F)

%Growth

6.84 7.06 32.31 34.61 7.14

8.71 12.92 43.33 66.54 53.57

805.06 574.52 3841.98 4341.77 13.01

54.65 45.48 346.37 289.88 -16.31

EXPORT

Source: Ministry of Commerce and Industry

Unit: USD Millions

6.84

7.06

32.31

34.61

7.14

8.71

12.92

43.33

66.54

53.57

805.06

574.52

3841.98

4341.77

13.01

54.65

45.48

346.37

289.88

-16.31

MA Y 2021 (F ) MA Y 2022 (F ) JA N-

MA Y 2021 (F )

JA N-

MA Y 2022 (F )

% GROW T H

NATURAL FIBRE EXPORT

SILK

WOOL, FINE OR COARSE ANIMAL HAIR, HORSEHAIR YARN AND WOVEN FABRIC.

COTTON.

OTHER VEGETABLE TEXTILE FIBRES; PAPER YARN AND WOVEN FABRICS OF PAPER

YARN.

market report](https://image.slidesharecdn.com/tvcjuly2022-231017111742-25c0f843/75/Textile-Value-Chain-July-2022-64-2048.jpg)