The document discusses athleisure clothing, which is a hybrid style typically worn for both athletic activities and casual occasions. It notes that the global sportswear market was estimated at $262.51 billion in 2019, expected to reach $288.42 billion in 2020, though another report stated it hit $533.5 billion that year. The author then says they will only provide a brief overview and not discuss the entire topic, noting the term "athleisure" was recently coined to blend the meanings of leisure and athletic wear.

![21 AUG 2022

textilevaluechain.in

NTU SINGAPORE & RGE LAUNCH

S$6 MILLION RESEARCH CENTRE TO

TACKLE TEXTILE WASTE

Nanyang Technological University, Singapore

(NTUSingapore)andRoyalGoldenEagle(RGE),

a global resources-based manufacturing

group, has launched the RGE-NTU Sustainable Textile

Research Centre (RGE-NTU SusTex) to accelerate

innovation in textile recycling and translate research

outcomesintopracticalsolutionsthatcanbedeployed

in urban settings like Singapore. Researchers in the

S$6 million joint research centre will look into areas

such as next-generation eco-friendly and sustainable

textiles, and refabricating textile waste into fibre.

The aim is to study the chemistry of various textile

materials and determine the optimal processes and

techniques required to bring us closer to a circular

textile economy. This is in line with Singapore’s Zero

Waste vision, as well as the Singapore Green Plan

2030.

The research centre, located at NTU’s School of

Materials Science and Engineering, was officially

launched on August 5, 2022 by Ms Grace Fu,

Singapore’s Minister for Sustainability and the

Environment.

It comes at a time when an estimated 92 million

tonnes of textile waste [1] is created globally each

year.Only12percentofthematerialusedforclothing

ends up being recycled. The textile industry itself is

responsible for 10 per cent of global greenhouse gas

emissions [2] – more than international flights and

maritime shipping combined.

NTU President Professor Subra Suresh said: “The

goal of the RGE-NTU Sustainable Textile Research

Centre (RGE-NTU SusTex) is very much aligned with

Singapore’s zero waste vision to build a sustainable,

resource-efficient and climate-resilient nation.

This partnership between NTU and RGE draws on

RGE’s industry experience as a global resources-

based manufacturing group and leverages NTU’s

intellectual assets in materials and environmental

chemistry.”

RGE Executive Director, Perry Lim, said: “We want to

contribute where we can achieve the most impact.

More countries are banning the import of waste

including textile waste. However, current textile

recycling technologies, which rely on a bleaching and

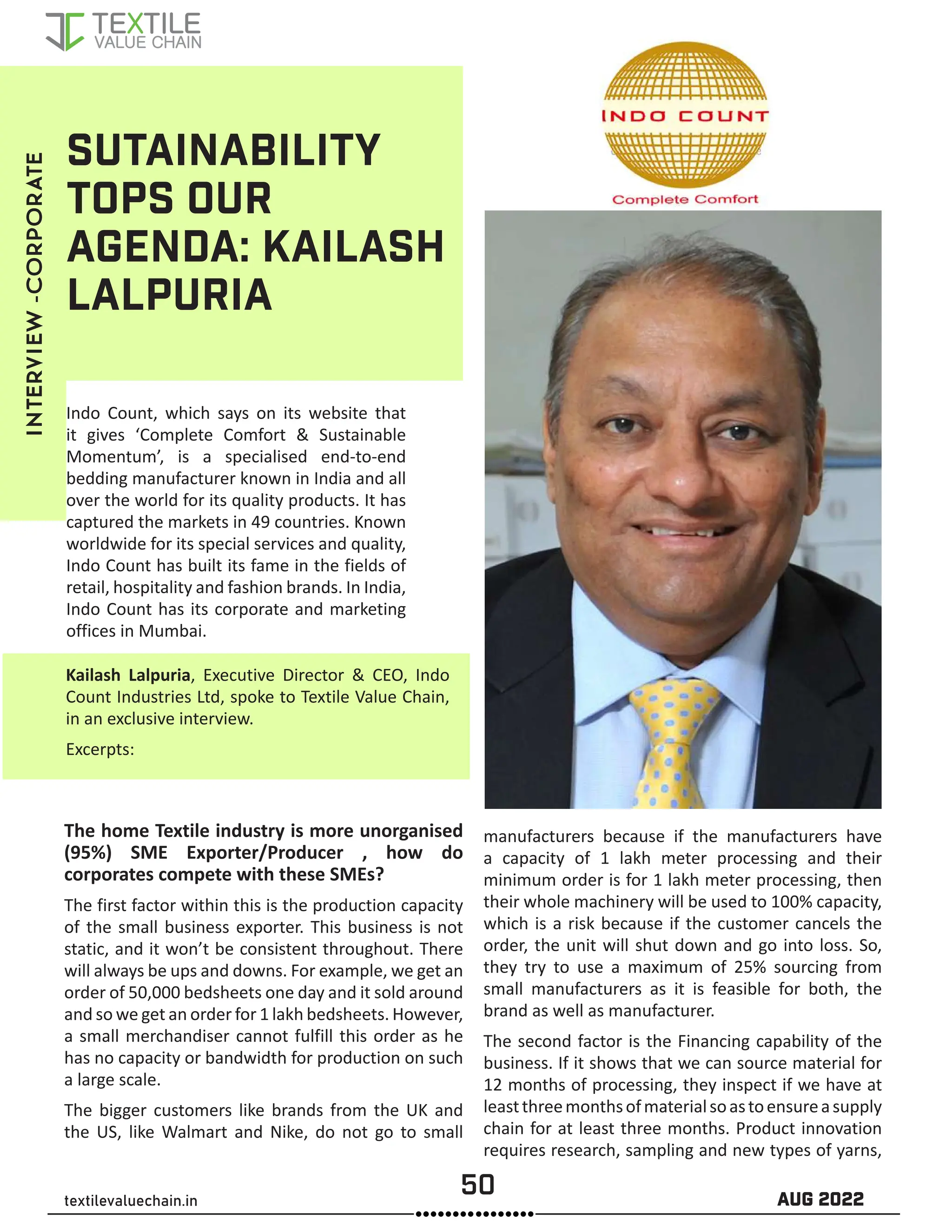

separation process using heavy chemicals, cannot be

implemented in urban settings such as Singapore.

This is where RGE can help, drawing on our 20 years

of experience in viscose fibre making, to provide

S$6 million in funding to establish the research

centre and fund its work; share our global R&D

expertise as the world’s largest viscose producer;

and to potentially scale up the viable innovations

and solutions across our global operations. Backed

by Singapore’s strong research ecosystem and

leveraging NTU’s engineering capabilities, we aim

to catalyse innovation and develop a first-of-its-kind

urban-fit textile recycling solution.”

NTU Senior Vice President (Research) Professor Lam

Khin Yong said: “Collaboration between universities

waste

manangement

Source: Nanyang Technological University,

Singapore ; RGE](https://image.slidesharecdn.com/tvcaugust2022-231017111924-3f6a4806/75/Textile-Value-Chain-Aug-2022-21-2048.jpg)

![22 AUG 2022

textilevaluechain.in

and the industry has never been more important to

tackle today’s complex social, environmental and

economic challenges. The RGE-NTU SusTex is yet

another example of how the culture of collaboration

with industry is embedded in NTU’s innovation

ecosystem. Such collaborations allow for a healthy

exchange of ideas and know-how between industry

and academia, and help pave the way for the

translation of research ideas, maximising the reach

and impact of NTU’s research for society’s benefit.”

Singapore Economic Development Board’s (EDB)

Senior Vice President, Dino Tan said: “The successful

launch of RGE-NTU SusTex is a testament to EDB’s

efforts in connecting our corporates with Singapore’s

research institutes. We are confident that by

combining RGE’s manufacturing expertise with

NTU’s research capabilities, the new research centre

will represent a significant step towards meeting

Singapore’s sustainable manufacturing goals. We

look forward to forging more such partnerships,

to support the development of innovative green

technologies and solutions that can be scaled in

Singapore and the region.”

The joint research centre is part of NTU’s ambition

andeffortstomitigateourimpactontheenvironment

under its NTU 2025 strategic plan, and builds on

RGE’s sustainability commitment, part of which is to

explore how waste can also be used as a resource to

generate new materials.

Drivinghigh-impactresearchthroughinterdisciplinary

collaboration

The RGE-NTU SusTex leverages the University’s

emphasis on interdisciplinary collaboration to

catalyse high-impact research and take innovative

ideas from the lab to the real world. It also builds

on RGE’s wealth of industry experience and strong

manufacturing capabilities. EDB seeded the

relationship between NTU and RGE

when the idea of an urban-fit textile recycling centre

was first germinated last year.

Thejointresearchcentrewilldrawupontheexpertise

of NTU scientists in the School of Materials Science

and Engineering and the School of Chemical and

Biomedical Engineering.

It will look into four research areas:

•Cleaner and more energy efficient methods

of recycling: looking at greener ways of textile

recycling, with a focus on cellulose-based fabrics

including rayon, viscose and cotton, minimising the

degradation of fabric properties, and refabricating

textile waste into fibre;

•Automated sorting of textile waste: using a

combination of advanced spectroscopic techniques

and machine learning capabilities for identifying and

sorting textile waste based on fibre composition,

and developing an automated system to remove

accessories such as zips and buttons;

•Eco-friendly dye removal: developing eco-

friendly methods of removing dye from textile

waste using little to zero chlorinated chemicals,

and formulating greener and biodegradable dye

substitutes;

•New textiles: finding alternative uses for

textile by-products and developing a new generation

of eco-friendly and smart textiles with attributes

such as moisture insensitivity, electrical conductivity,

and infrared/ ultraviolet radiation reflectivity.

Leading the joint research centre in these research

projects is Professor Hu Xiao from the NTU School of

Materials Science and Engineering, who is also the

director of the Environmental Chemistry & Materials

Centre at NTU’s Nanyang Environment & Water

Research Institute.

In conjunction with the establishment of the RGE-

NTU SusTex, RGE plans to build a textile recycling pilot

plant that is low carbon, low chemical emissions, and

energy efficient in Singapore. The new sustainable

textile recycling solutions developed under the RGE-

NTU SusTex are expected to be test bedded in this

pilot plant.

[1] Why clothes are so hard to recycle, BBC, 13

Jul 2020

[2] The impact of textile production and waste

on the environment, European Parliament

News, 26 Apr 2022](https://image.slidesharecdn.com/tvcaugust2022-231017111924-3f6a4806/75/Textile-Value-Chain-Aug-2022-22-2048.jpg)

![37 AUG 2022

textilevaluechain.in

AIR PERMEABILITY ;

TEAR RESISTANCE OF FABRICS FOR

PPE PROTECTION

1.Introduction

During demonstrations and riots, more and more

fire bombings are carried out with Molotov cocktails.

Apart from damage to property such as house or car

fires, personal injuries are also caused. Increasingly,

police and fire brigade personnel suffer damage from

Molotov cocktail explosions. These explosions result

in serious injuries, some with fatal consequences.

[1–11]

Molotov cocktail attacks (MCA) are counted as

“politically motivated crime, especially bodily harm

and homicide” [12]. In 2020, the MCA increased by

18.82 % compared to the previous year [13].

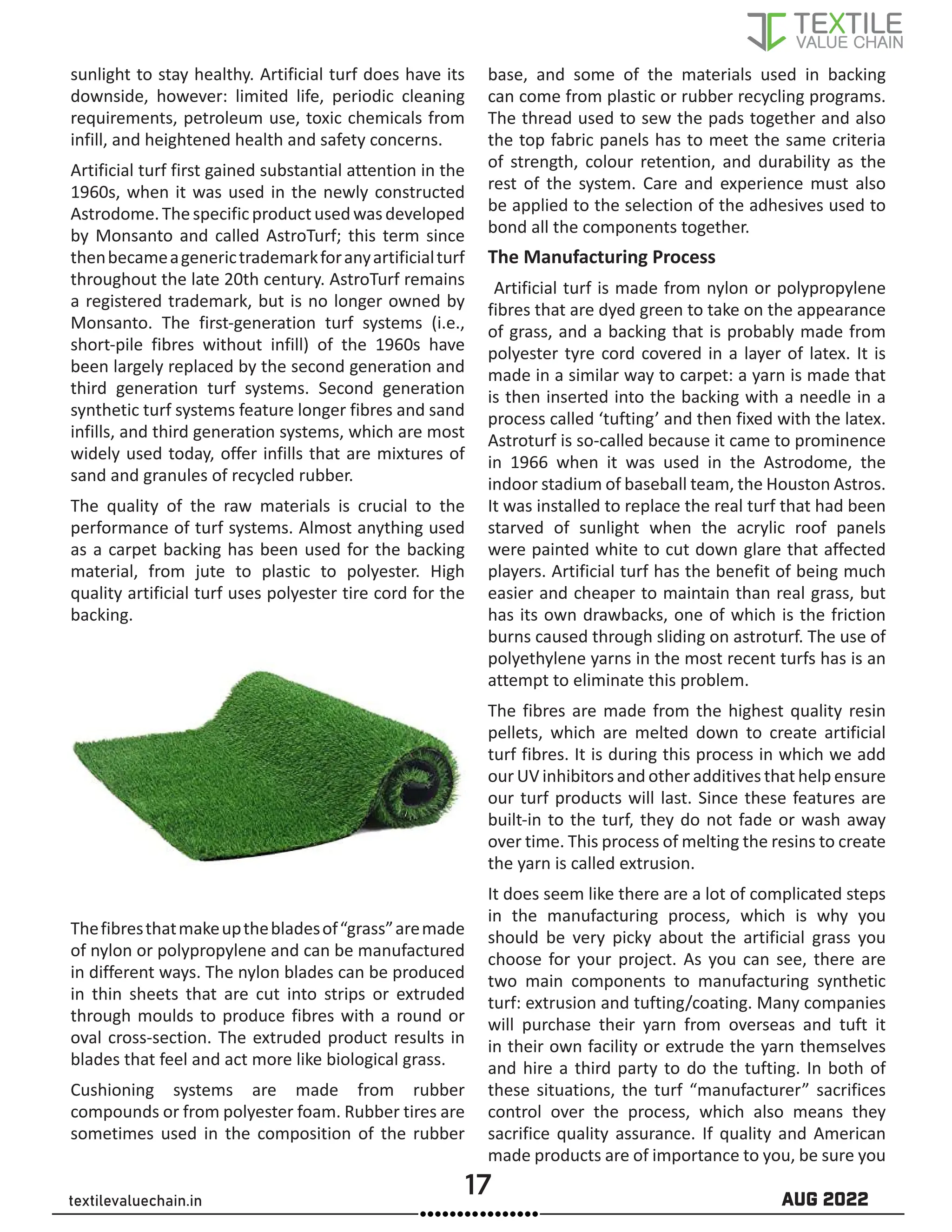

Figure 1 shows the development of the number

of violent offences per year in comparison to the

number of injured police officers (PVB). It can be

seen that the number of injured persons increases

more than the number of violent acts carried out

[14].

(Figure 1): Development of violent attacks on

German police officers [14]

The personal protective equipment (PPE) of a

police member is mostly made of aramid blend

fabric. The melting temperature of aramid is 600 °C

[15]. A Molotov cocktail explosion reaches higher

temperatures between 800 °C and 1700 °C [16,

17]. When PPE made of aramid is exposed to these

temperatures, the material contracts, it shrinks and

it begins to decompose. The melting material itself

causes severe injuries to the skin [18]. The parts of

the body exposed by the shrinkage are defenceless

against direct fire.

To improve the protective effect of PPE against MCA,

research is being conducted on a new fibre material,

new fabric patterns and a new coating [19]. However,

this article focuses on the development of new fabric

patterns.

The new fabric should offer the police officers at least

the same protection as the old fabric and additionally

reduce the shrinkage. The current tasks of the PPE

include [20]:

y

y Protection against cold

y

y Stab resistance

y

y Wearing comfort

y

y Impact resistance

y

y Fire protection

y

y Freedom of movement

y

y Wind and rain protection

y

y Easy care

y

y Abrasion resistance

Rahel Krause Justin Kühn Thomas Gries

Institut für Textiltechnik of

RWTH Aachen University,

Aachen, Germany.

TECHNICAL

TEXTILE](https://image.slidesharecdn.com/tvcaugust2022-231017111924-3f6a4806/75/Textile-Value-Chain-Aug-2022-37-2048.jpg)

![38 AUG 2022

textilevaluechain.in

Air permeability and tear resistance are determined

in order to better assess cold protection, stitch

resistance and wearing comfort. The air permeabil-

ity and tear resistance are determined to compare

the new weaves and to find a possible correlation

between air permeability and tear resistance. High

air permeability increases comfort. The tear strength

is needed to assess the tear resistance.

2.Experimentation

In the following, the execution of the tests

(Determination of tear force of trouser-shaped test

specimensaccordingtoDINEN13937,airpermeability

according to DIN EN ISO 9237) is explained. First, the

new bindings with which the tests are carried out are

presented. For each experiment, the experimental

design, execution and results are explained.

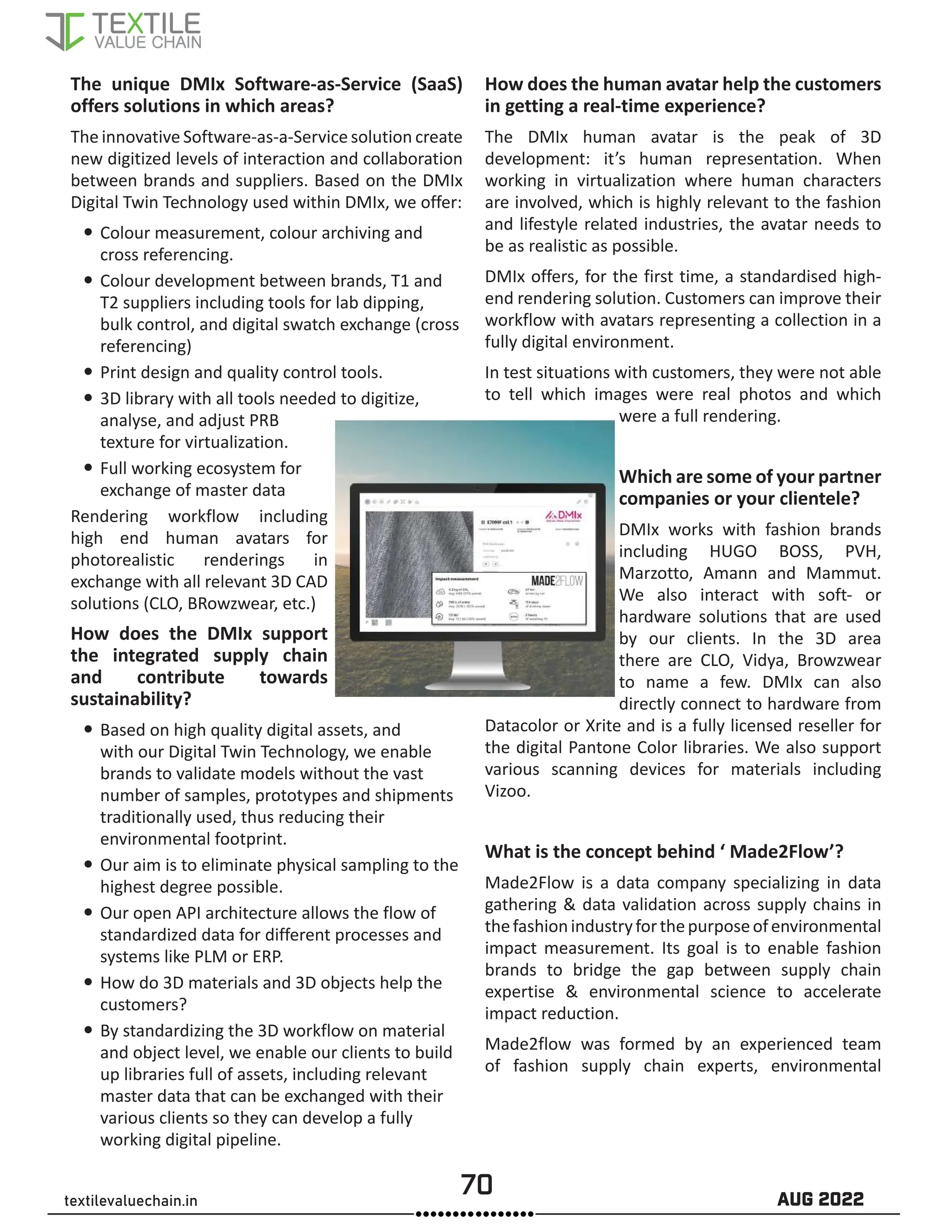

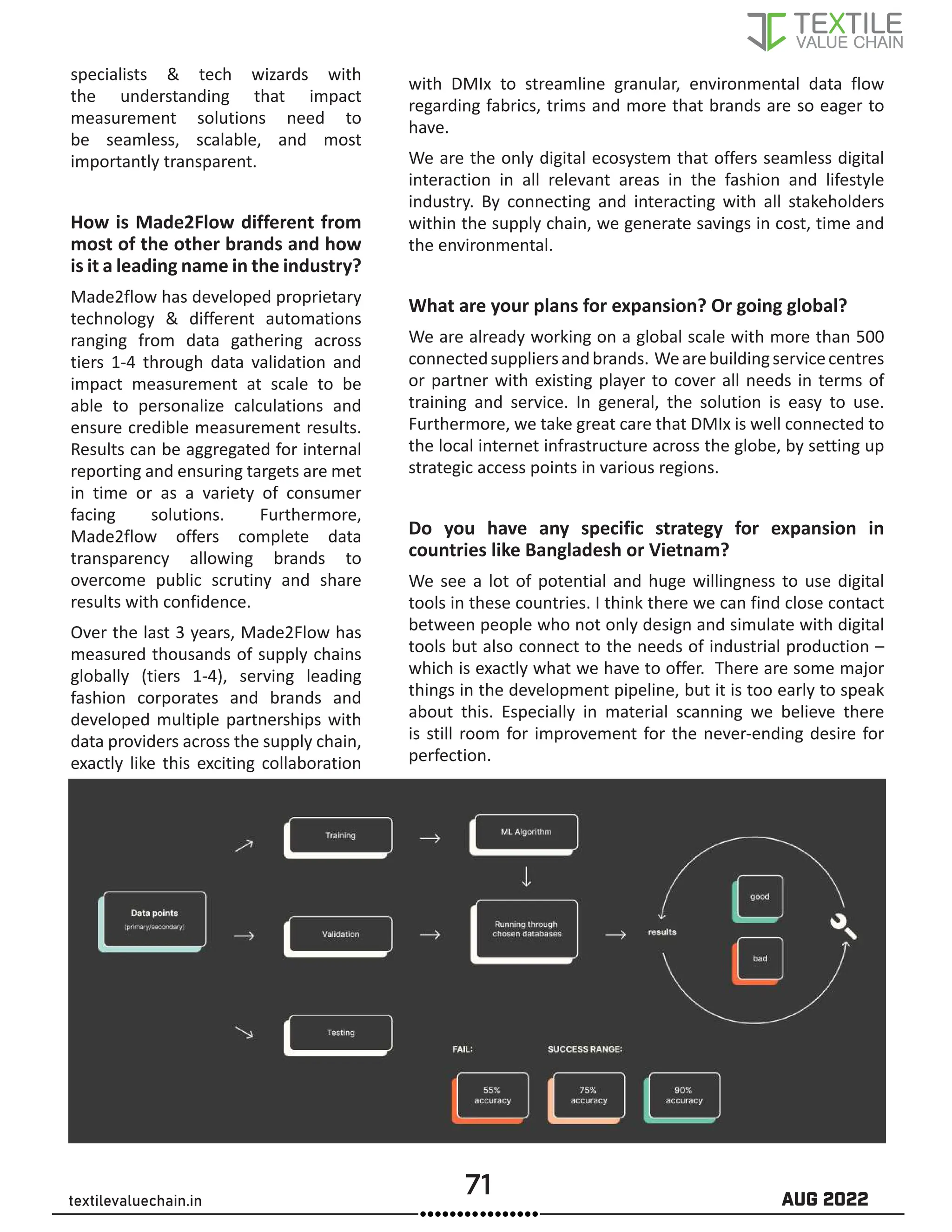

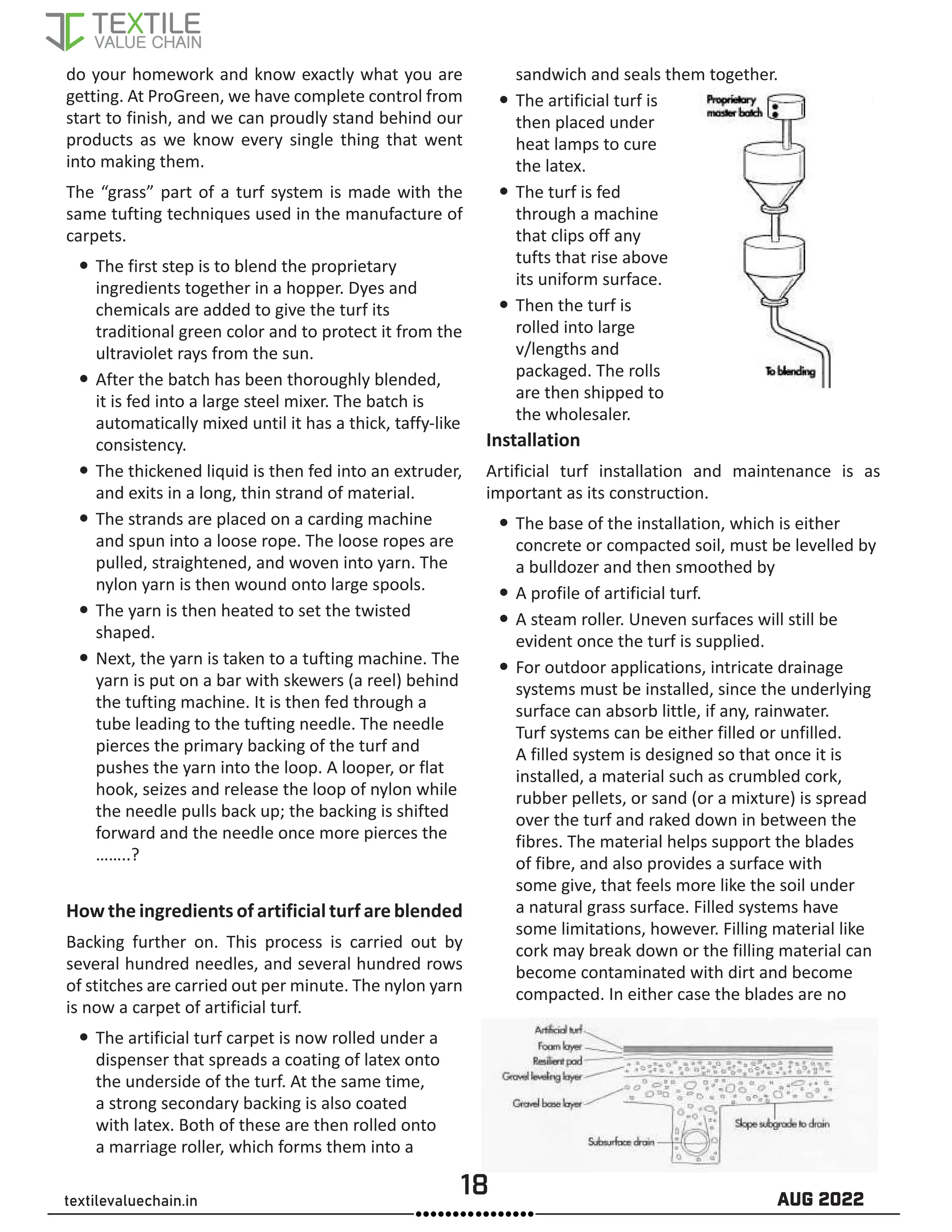

2.1 New fabric patterns

When PPE is exposed to the high temperatures of a Molotov cocktail explosion, the material shrinks. The

shrinkage of the textile causes the material to contract and the garment to fit tightly around the skin. The

insulating effect of the air cushion is lost. Areas of the body such as the ankles or wrists are exposed. Direct

contact with the fire causes severe injuries to these parts of the body. Textiles used to make fire-retardant

clothing are currently made of aramid fabrics with a 3/1 twill weave [15]. Independent of a new material

for PPE, three new fabric weaves have been developed. These weaves should have a maximum shrinkage of

1.5 %. The wearing comfort should still be given or improved with the new material [19]. In order to assess

the influence of the weave on the properties of the fabric independently of the material, the three new

weaves were developed and woven from m-aramid yarn. The weaves were developed by the project partner

Sächsisches Textilforschungsinstitut e.V., Chemnitz, Germany (STFI).

Table 1: New types of fabric weaves (black: warp lift, white: warp lowering).](https://image.slidesharecdn.com/tvcaugust2022-231017111924-3f6a4806/75/Textile-Value-Chain-Aug-2022-38-2048.jpg)

![39 AUG 2022

textilevaluechain.in

Weave no. 1 consists of a combination of rep elements. The resulting ribs lead to a high thread density. The

weave points of the first weave are close together.

Weave no. 2 is a combination of the plain weave and its simplest variants, the rep and the panama weave.

The plain and rep elements give the fabric structure and stability. The larger Panama weave elements create

a float as the weave points are further apart.

Weave no. 3 combines two twill weaves. A twill with a Z degree is interrupted by a twill with an S degree.

Untypical for the twill weave is that there are the same number of warp and weft threads on each side. The

side of the fabric does not influence the property profile.

2.2 Determination of the tear strength

For the initial assessment of the new weaves, only

small amounts of fabric are woven (an area of

600x1000 mm per weave). The leg tear test is carried

out in accordance to the DIN EN ISO 13937 standard.

Samples with dimensions of 50 mm x 200 mm are

taken from the fabrics. Two sets of five samples per

fabric are taken. One set of samples in warp direction

and one in weft direction. According to the standard,

in one set of samples no two samples should contain

the same warp or weft threads. Due to the small

size of the woven fabrics, the arrangement of the

samples cannot be done according to the standard.

To determine the tear strength across the warp, only

four instead of five samples can be taken from weave

no. 3. The tests are carried out in a standard climate

at 20.7 °C and a relative humidity of 66 %. [21]

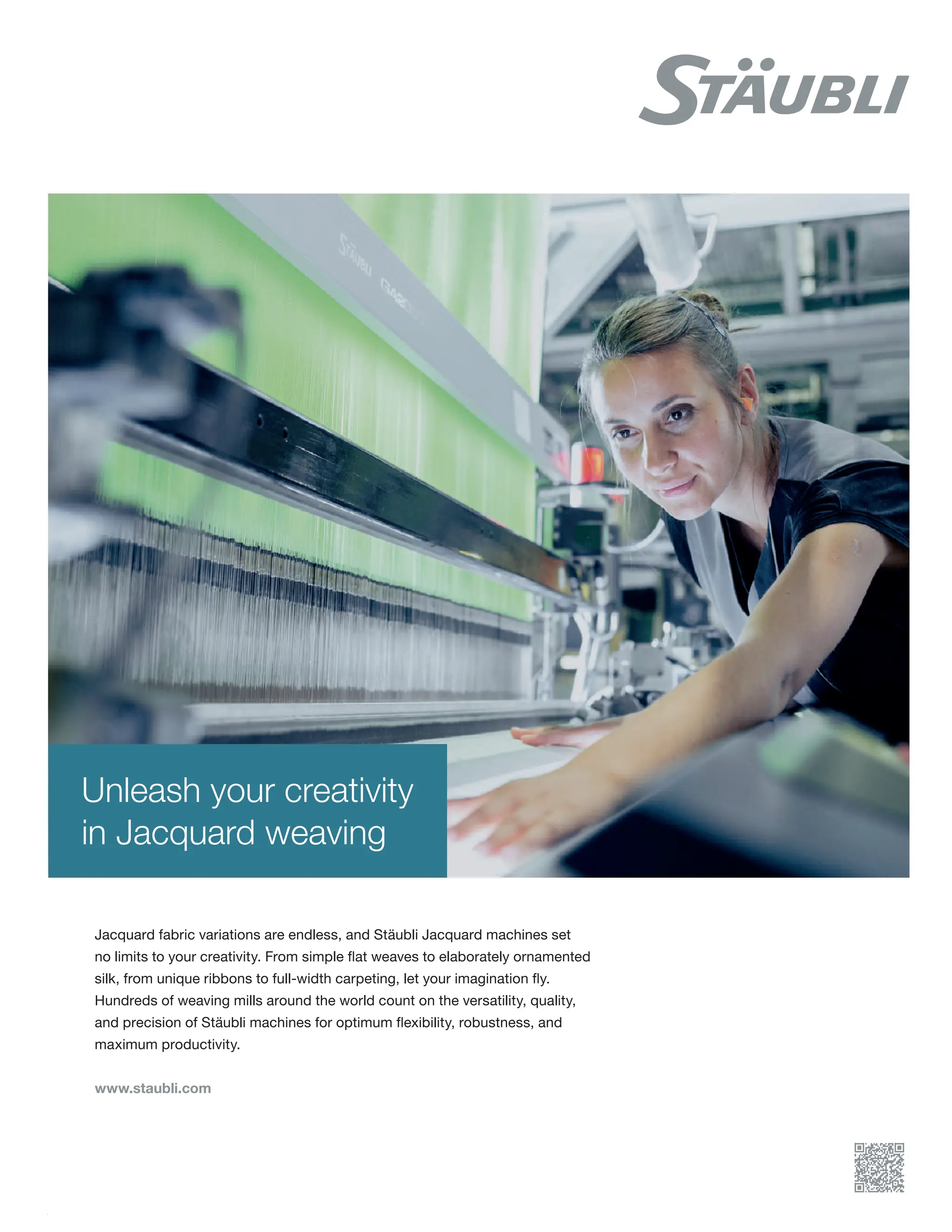

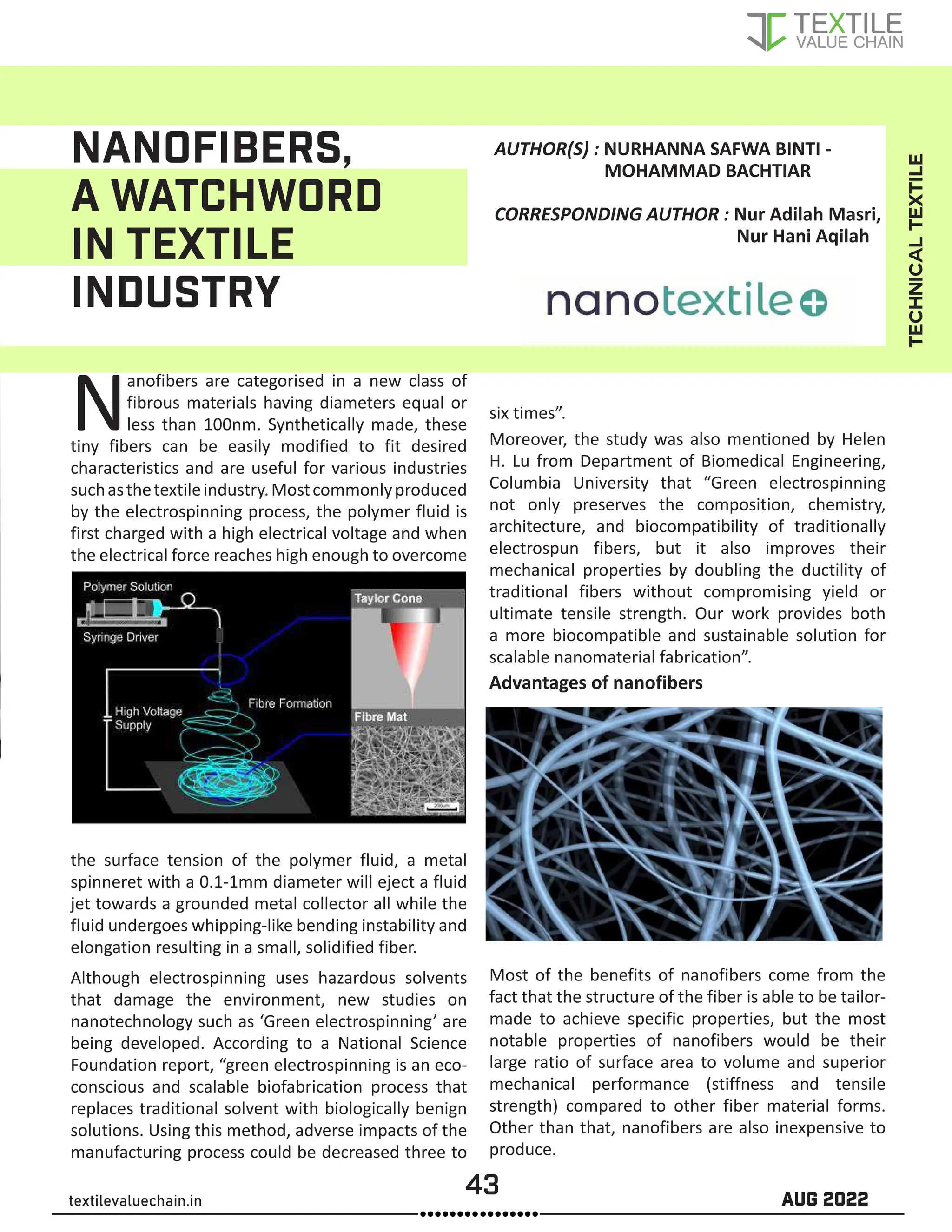

Weave no. 1 achieves the highest tear strength

crosswise to the warp (131 N). The thread density

is very high due to the interlocked rep weaves. The

characteristic ribs form a tight weave with many,

closely spaced weave points. The visible difference

in tear strength across the warp and across the weft

is due to the different orientation of the ribs in the

fabric.

Weave no. 2 (120-122 N) and weave no. 3 (78 N) have

almost the same tear strength in both directions. The

reason for this is the symmetrical construction of the

weave cartridges. Weave no. 2 consists partly of the

plain weave and the Panama weave, which have the

same properties in both warp and weft directions. In

weave no. 3, the symmetry of the fabric results from

the combination of the Z and S degrees, as well as

the even distribution of the warp and weft threads.

In Figure 2 the tear strength of the different fabric is

shown.

(Figure 2): Tear strength per weave and direction

2.3 Determination of air permeability

The testing device offers sufficient space to test the

fabrics non-destructively. After each test, the fabric

is moved alternately by 20 cm in the warp and weft

directions. This means that the test preparation and

thedeterminationoftheairpermeabilityarecarried

out as per the standard. The tests take place in a

standard climate at 20.7 °C and a relative humidity

of 66 %. The fabric is clamped into the 20 cm2 test

area for each test. Care is taken to ensure that there

are no folds and that the edge seals the test surface

from the environment. A differential pressure of

200 Pa is applied to the sealed sample and the

air permeability is determined. For each fabric, a

reference measurement is taken with a rubber plate

to determine the leakage rate. The leakage rate is a

measure of how much air escapes through the seal.

This value is subtracted from the measured values

to determine the actual air permeability. [22]

Figure 3 below shows the results of the tests to

determine the air permeability for each of the new

fabric weaves.](https://image.slidesharecdn.com/tvcaugust2022-231017111924-3f6a4806/75/Textile-Value-Chain-Aug-2022-39-2048.jpg)

![41 AUG 2022

textilevaluechain.in

[1] Jager J.; Klatt T.; Bliesener T. NRW-Studie zur „Ge-

walt gegen Polizeibeamtinnen und Polizeibeamte.

Die subjektive Sichtweise zur Be-treuung und Für-

sorge, Aus- und Fortbildung, Einsatznachbereitung,

Belastung und Ausstattung: Kiel, 2013.

[2] Schwetje, S. Ausschreitungen im nordirischen

Londonderry. https://www.n-tv.de/ticker/Auss-

chreitungen-im-nordiri-schen-Londonderry-arti-

cle21263687.html (Accessed April 19, 2022).

[3] Otruba, F. POL-Pforzheim: (FDS) Horb - Glück-

licherweise nur geringer Schaden nach Wurf

mit Molotow-Cocktail in Richtung Polizeige-

bäude. https://www.presseportal.de/blau-licht/

pm/137462/4585984 (Accessed April 19, 2022).

[4] Mladek, J. Brandanschlag auf Polizeirevier in

Greifswald. https://www.nordkurier.de/mecklen-

burg-vorpommern/brandanschlag-auf-polizeirevier-

in-greifswald-0839626006.html (Accessed April 19,

2022).

[5] Kramper, G. Unruhen nach dem Tod von George

Floyd. https://www.stern.de/panorama/stern-

crime/new-york--junge-frau-schleudert-molotow-

cocktail-auf-polizeiwagen-9283384.html (Accessed

April 19, 2022).

[6] Spilker, I. Freund oder Feind? https://www.torial.

com/isabell.spilker/portfolio/376848.

[7] N.N. Verfassungsschutzbericht Bayern 2016:

München, April 2017.

[8] N.N. Politisch motivierte Konfrontationsgewalt

- Auseinandersetzungen zwischen links- und recht-

sorientierten Akteuren in den Jahren 2011 – 2012 /

Auszüge aus dem Abschlussbericht, 2016.

[9] N.N. Straftaten gegen Polizeibeamte - Lageber-

icht 2012: Dresden, April 2013.

[10] N.N. Straftaten gegen Polizeibeamte - Lageber-

icht 2011: Dresden, Mai 2011.

[11] N.N. Straftaten gegen Polizeibeamte - Lageber-

icht 2010: Dresden, Februar 2011.

[12] Waffengesetz (WaffG) Anlage 2 (zu § 2 Abs. 2

bis 4) Waffenliste, 2002.

[13] N.N. 1 Politisch motivierte Kriminalität im Jahr

2020: Bundesweite Fallzahlen, May 04, 2021.

[14] Gewalt gegen Polizeivollzugsbeamtinnen und

Polizeivollzugsbeamte: Bundeslagebild 2020, 2020.

[15] N.N. Technische Lieferbedingungen Polizei des

Landes Nordrhein-Westfalen: TLP Nr. 9004, 03.2019.

[16] Schröter, T. Bilddatengestützte Erkennung von

Deflagrationen: Hamburg, 2016.

[17] Grabski, R.; Brein, D.; Pasch, U.; Neske, M.;

Kunkelmann, J. Brandschutzforschung der Bun-

desländer,: Karlsruhe, 2010.

[18] Lier, A. Bei der Berliner Polizei brennt die

Uniform durch. https://www.bz-berlin.de/berlin/

bei-der-berliner-polizei-brennt-die-uniform-durch.

[19] Krause, R.; Bell, E. Schutzkleidungsmaterial

für Einsatzkräfte - Molotowcocktailschutz. https://

www.ita.rwth-aachen.de/global/show_document.

asp?id=aaaaaaaaaxtkqff (Accessed July 6, 2022).

[20] Technische Richtlinie (TR) Körperschu, 2009.

[21] DIN EN ISO 13937-2:2000-06, Textilien_-

Weiterreißeigenschaften von textilen Flächenge-

bilden_- Teil_2: Bestimmung der Weiterreißkraft mit

dem Schenkel-Weiterreißversuch (einfacher Weiter-

reißversuch) (ISO_13937-2:2000); Deutsche Fassung

EN_ISO_13937-2:2000; Beuth Verlag GmbH: Berlin.

[22] DIN EN ISO 9237:1995-12, Textilien_-

Bestimmung der Luftdurchlässigkeit von textilen

Flächengebilden (ISO_9237:1995); Deutsche Fas-

sung EN_ISO_9237:1995; Beuth Verlag GmbH:

Berlin.

References

explore fashion industry on

fashionvaluechain.com

for collaboration write us on fashionvaluechain@gmail.com](https://image.slidesharecdn.com/tvcaugust2022-231017111924-3f6a4806/75/Textile-Value-Chain-Aug-2022-41-2048.jpg)

![46 AUG 2022

textilevaluechain.in

INDIA’S E- COMMERCE INDUSTRY’S

FUTURE VIS A VIS EMERGENCE OF

OPEN PLATFORM ONDC AND RELIANCE

RETAIL’S THREAT TO MEGA CORPORATE

AMAZON, FLIPKART.

1:STATUS AND SIZE OF INDIA’S E COMMERCE ONLINE RETAIL

INDUSTRY,TODAY

For India’s total population of 140 Billion, the overall size

of Retail markets today stands at approx. $ 900 Billion in its

turnover. It is projected to grow to the market size of $1.3-1.4

Trillion by year 2025-26, of which 75-80% share to be for the

Food,Grocery, Apparel/fashion and lifestyle products. Yet this

will equal only 15% share for online E- commerce, which is

presently controlled by a Dozen mega players like Amazon,

Flipkart.

Key factors to be understood for future E commerce trajectory are mainly,

A] growth driven by ‘demographic’ dividend of India’s young well employed and earning population,

B] growth of millions of ‘mom and pop’ small residential area shops now evolving to Online selling,

C] growth coming in from faster spread of 4G ,WIFI and internet in semi urban and rural areas and

D] future growth in high speed data services from new emerging 5 G networks by end 2022-mid 23.

The battle for E- commerce Giants ,namely

Amazon, Flipkart and the new online players esp.

the Reliance retail and , the Tata groups.

In the hot bed of India’s e-commerce industry, there

are `battles and wars ` going in for grabbing the

increasing share of the Online e-commerce from the

ever growing retail market at 15% CARG with special

targeting of `middle class consumers, The `youth`

and fast emerging Tier 2.Tier 3 cities.

With its control on 4G and future 5G networks, and

its physical control on a million small to medium

`brick and mortar` physical retail stores [ in only 3-5

km of populated residential areas].

Reliance Retail is fast emerging as the biggest player

to be and hiving off big chunk of share of like of

existing giant and mega E-commerce players like

Amazon, Flipkart, DMart and Snap deal and others

and, over whom It has the best advantage of up-

cycling the 30% returns of E-commerce sales.

The ongoing battle of above giants is now on full

roll for the lucrative E-commerce Market share The

2 other major Indian conglomerates like TATA and

Birla groups are also spearheading their tentacles

fast to carve out their own share in India’s mega

e-commerce jungle. In this battle for market share,

it seems that Amazon would be further losing its big

pie under the new ONCD platform being launched

with he Govt support for the small size online

e-commerce business.

MUNISH TYAGI

retail

update

Textile Consultant](https://image.slidesharecdn.com/tvcaugust2022-231017111924-3f6a4806/75/Textile-Value-Chain-Aug-2022-46-2048.jpg)

![47 AUG 2022

textilevaluechain.in

The concept behind the govt supported ONDC

E-commerce platform to be understood as below:

A] the core objective and aim of new ONDC

e-commerce platform is mainly to enable Online sale

penetration of small sellers vis-a-vis the existing

large players like Amazon, Flipkart, others.

B] to facilitate the above, the ONDC online platform

will also provide embedded payment gateway.

Understanding the ONDC, open E-commerce

platform to support small sellers.

At its core, ONDC is an open network for E-commerce

underpinned by a set of open e commerce standards

similar to India’s very successful UPI - Universal

Payments Interface. In fact, the underlying open

standards of ONDC are an adapted version of the

Beckn Protocol, a global open source standard that

can be used even beyond retail commerce for sectors

such as mobility and health. Hospitality , and even

education.

If it works with its best operational efficiency as

expected, ONDC could fundamentally change the

game for e-commerce, herald a future of open

competition with less dominance by vertically

integrated existing Mega platforms, and show U.S.

regulators ways to take on their own monopolies.

An open E-commerce market for the future

ONDC is not an application, an intermediary, or a

specific piece of software. Rather, ONDC is a set of

specifications designed to foster open interchange

and connections between shoppers, technology

platforms, and retailers.

ONDC may provide a smooth entry for `mon and

pop stores` called kiranas, but ultimately all players

will benefit. Homegrown e-commerce competitors

to giants Flipkart and Amazon, such as SnapDeal,

who wish to compete on user experience and price

on a level playing field, are signing up for ONDC.

Google too has indicated interest. Indian technology

companies that provide e-commerce services and

capabilities to medium-sized businesses see ONDC

as a potential boon to their biz.

RELIANCE RETAIL GAME PLAY TO CHALLENGE THE

EXISTING DOMINANT PLAYERS

Reliance Group’s declared war and mega play

into India’s $900 billion retail market has taken an

aggressive mode as India’s Retail sector has now

emerged as one of the most dynamic industries and

is expected to reach anywhere between $1.3-$1.5

trillion by 2025-26. The organised retail along with

its Online or e-commerce rider seen gaining 15%

market share in the overall retail space, while food

& grocery and apparel and lifestyle may account for

80% of India’s retail market by 2025.

Large market offers big opportunities. And it looks

like Reliance Retail has seized it, with its massive

omni-channel retail play of physical stores, B2B with

kirana’s and e-commerce. With new Govt policy,

for open access E-commerce channels,The overseas

players like Amazon remain at handicap considering

that they cant expand physical Stores to only 20%

of their turnover and which would be far Yet far

lagging behind Reliance Retail’s.

The company already went on an acquisition spree

and partnerships in the last three years, adding to its

portfolio some of biggest names, including Hamleys,

Dunzo, Zivame.

It has also partnered with famous global retail chain

7-Eleven. Catering to India’s affluent consumers,

Reliance, meanwhile, houses some of the most

iconic brands such as Hamleys for toys and likes of

Versace, Armani Exchange, GAP, GAS, Jimmy Choo,

Michael Kors among others. The premium segment

has become one of the fastest growing categories.

Also firming up its inorganic play, the company is

planning to acquire dozens of niche local consumer

brands to build a formidable consumer goods

business to support its E-commerce.

Reliance Retails stays highly focused on growth via

the physical retail expansion. Reliance is looking to](https://image.slidesharecdn.com/tvcaugust2022-231017111924-3f6a4806/75/Textile-Value-Chain-Aug-2022-47-2048.jpg)