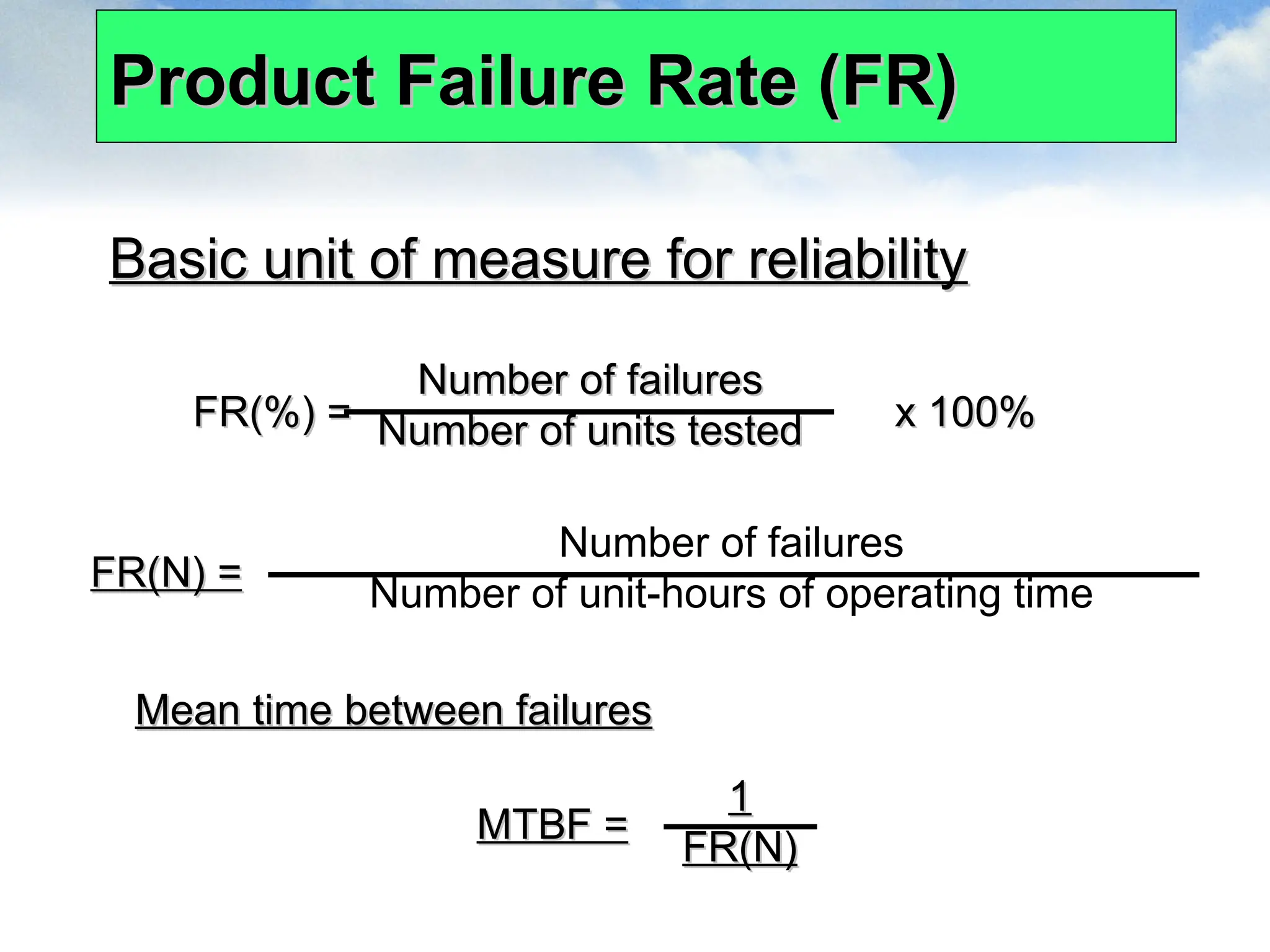

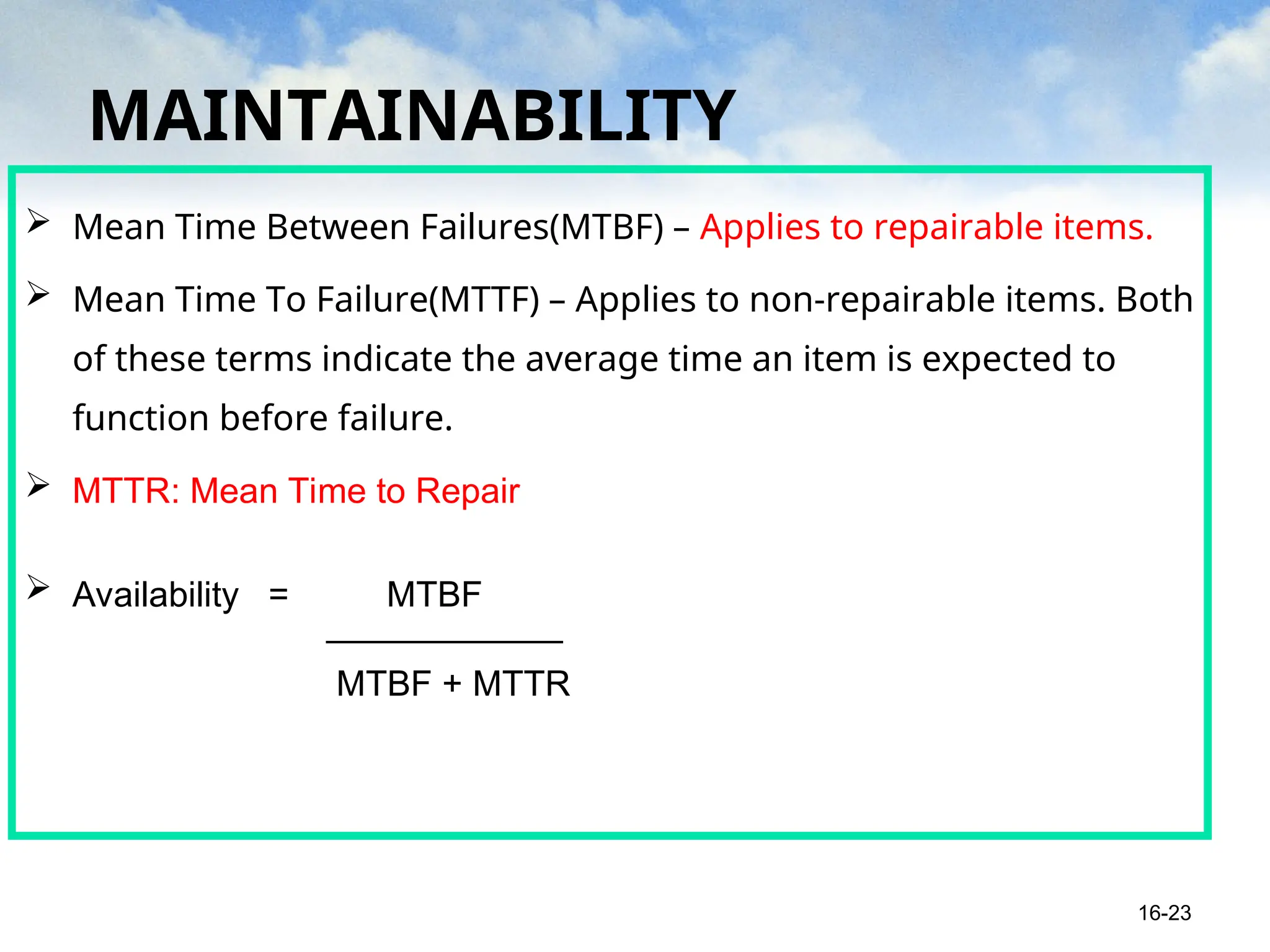

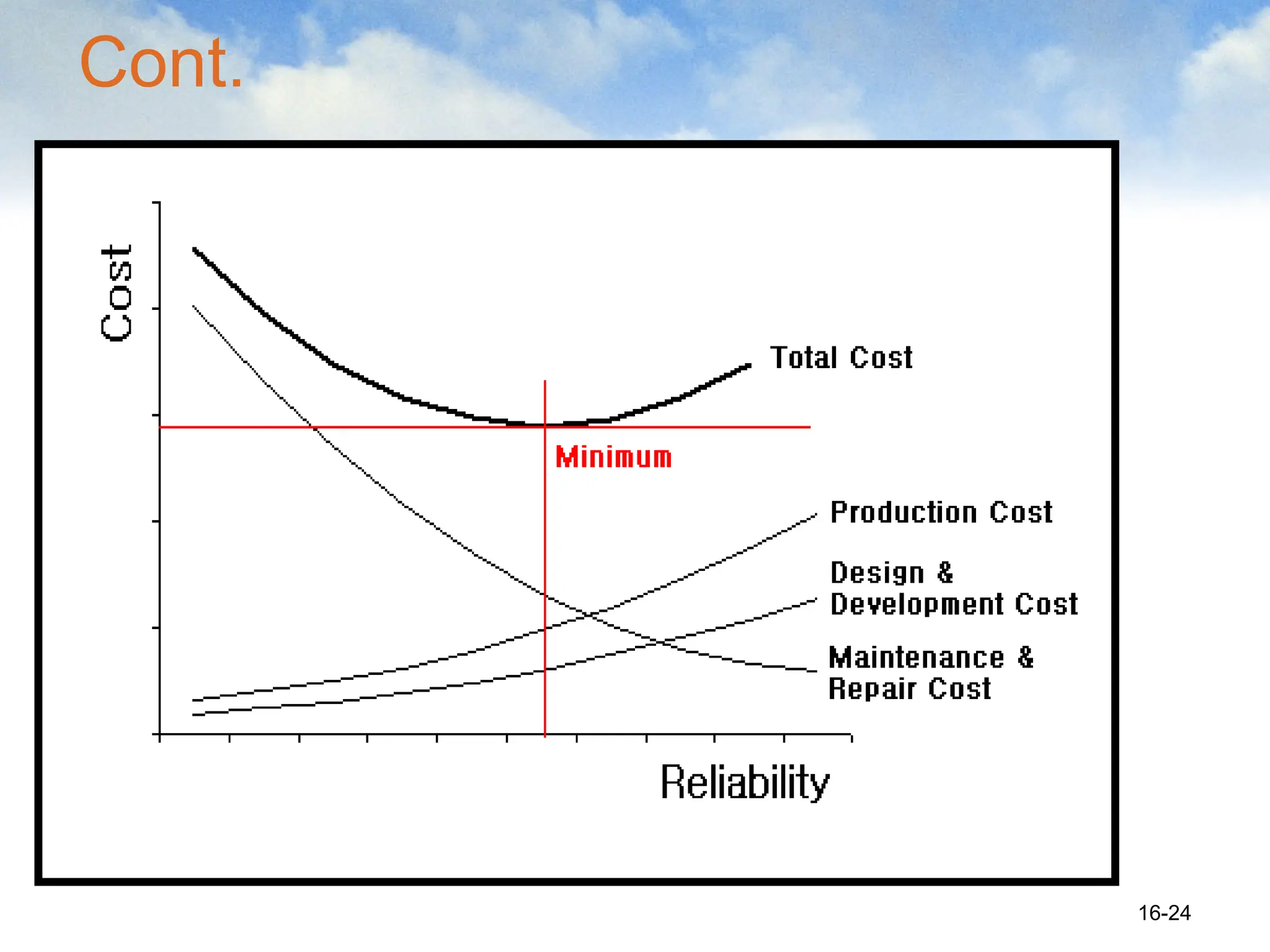

The document discusses the concepts of reliability and maintainability in systems, emphasizing their importance in maintaining system capability while controlling costs. Reliability is defined as the probability that a product or service will perform as intended for a specified period, influenced by factors such as component reliability and design complexity. It also highlights the interrelationship between quality, reliability, and maintainability, aiming for customer satisfaction through effective product design.