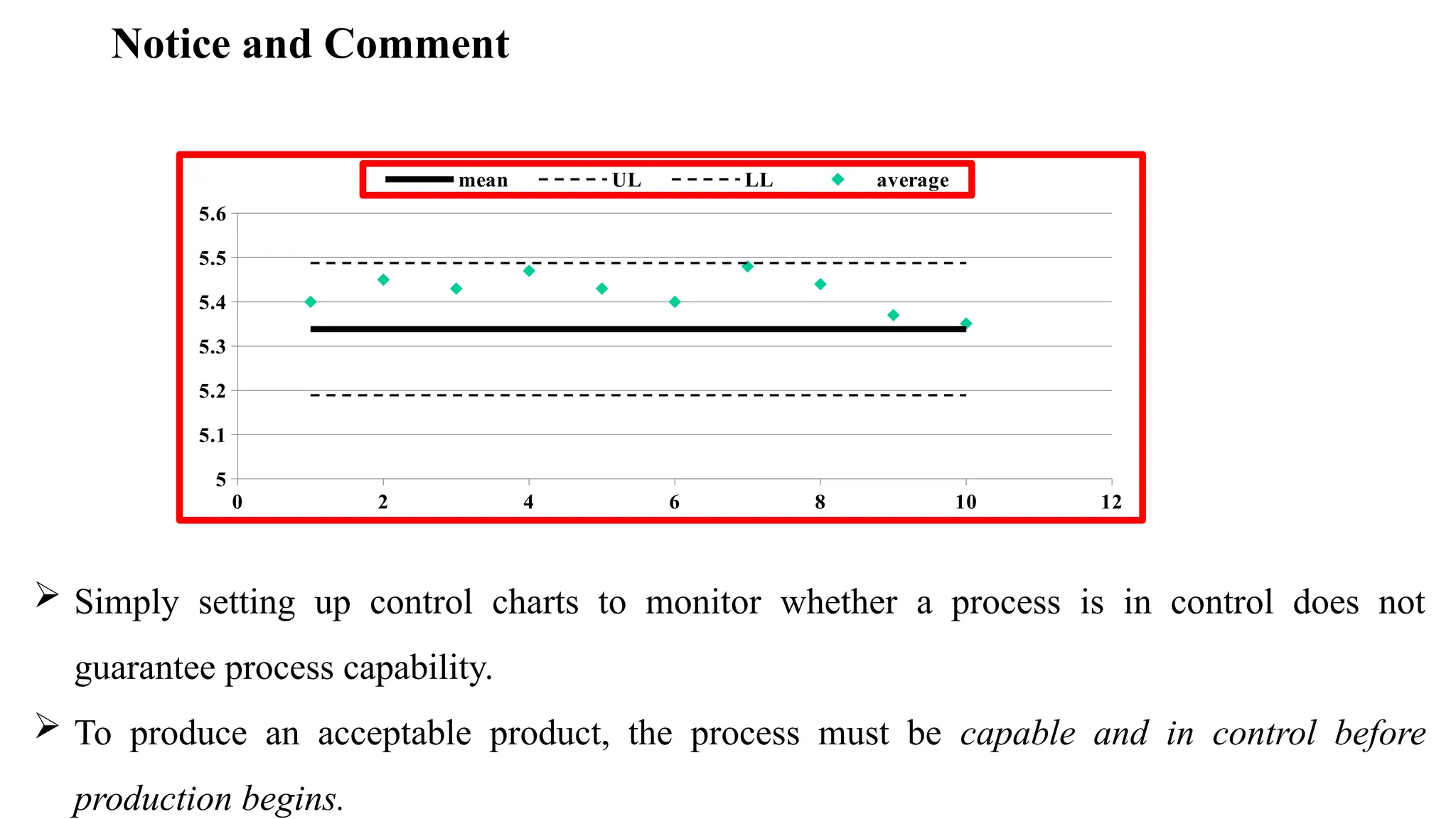

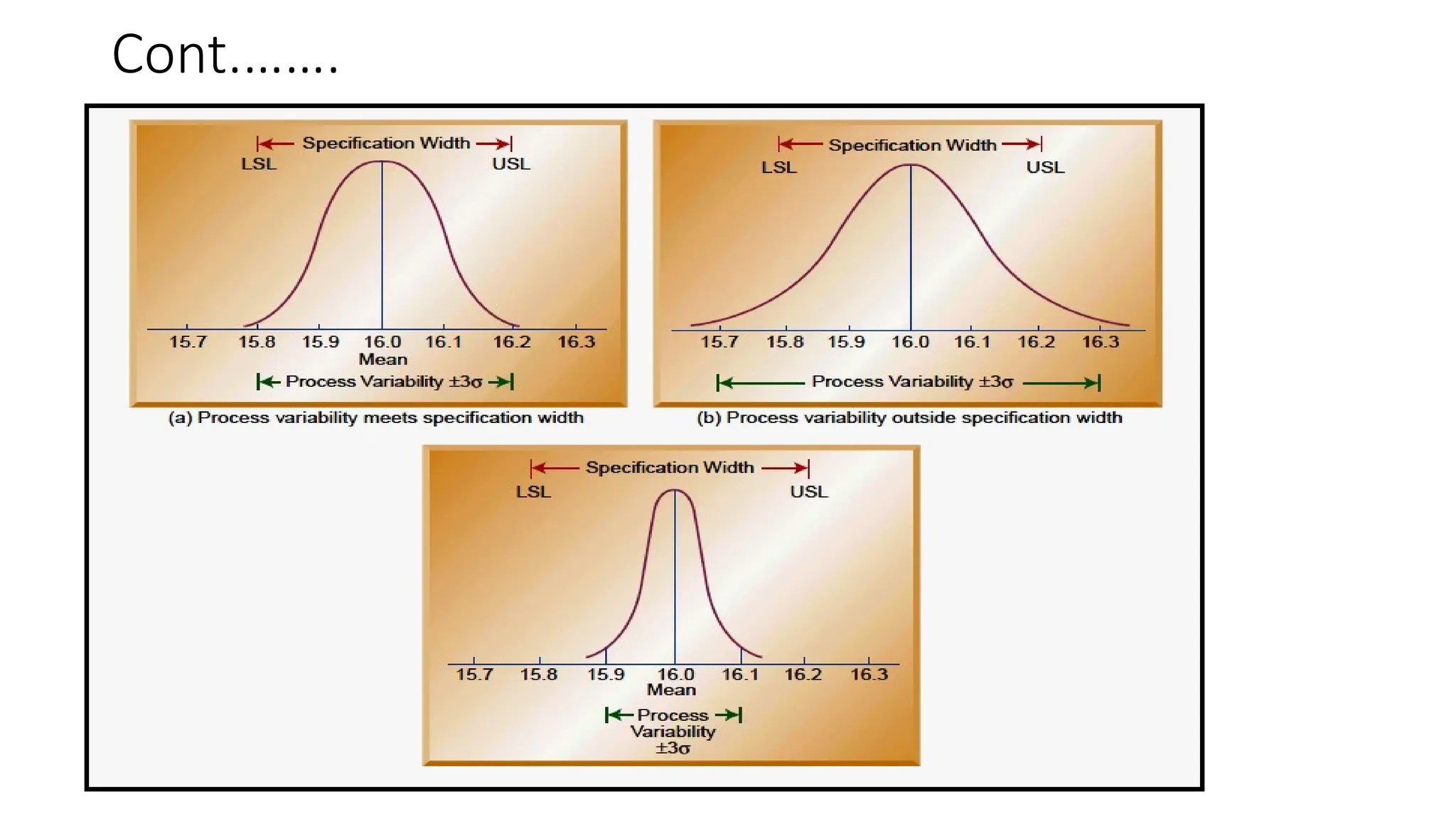

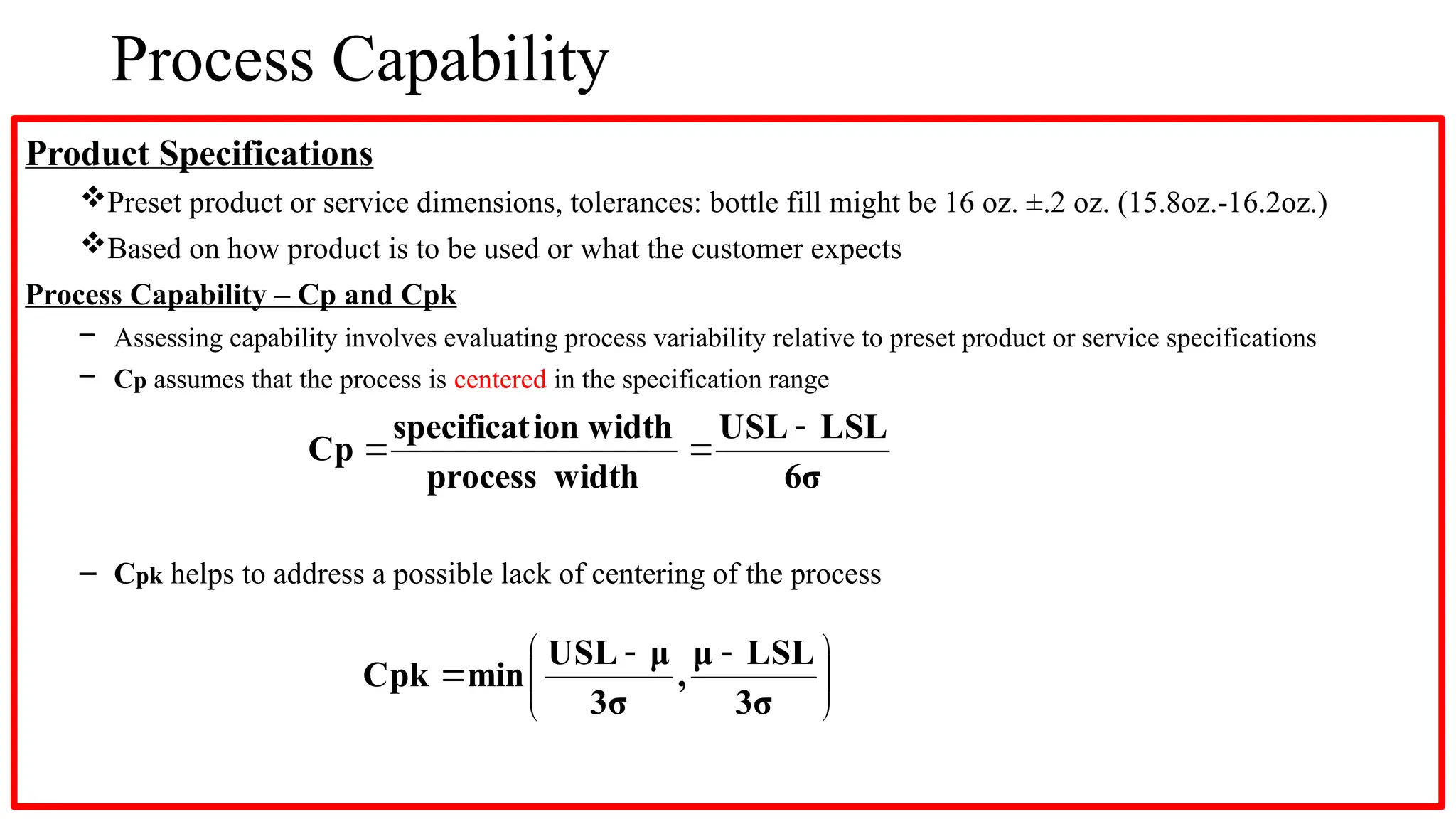

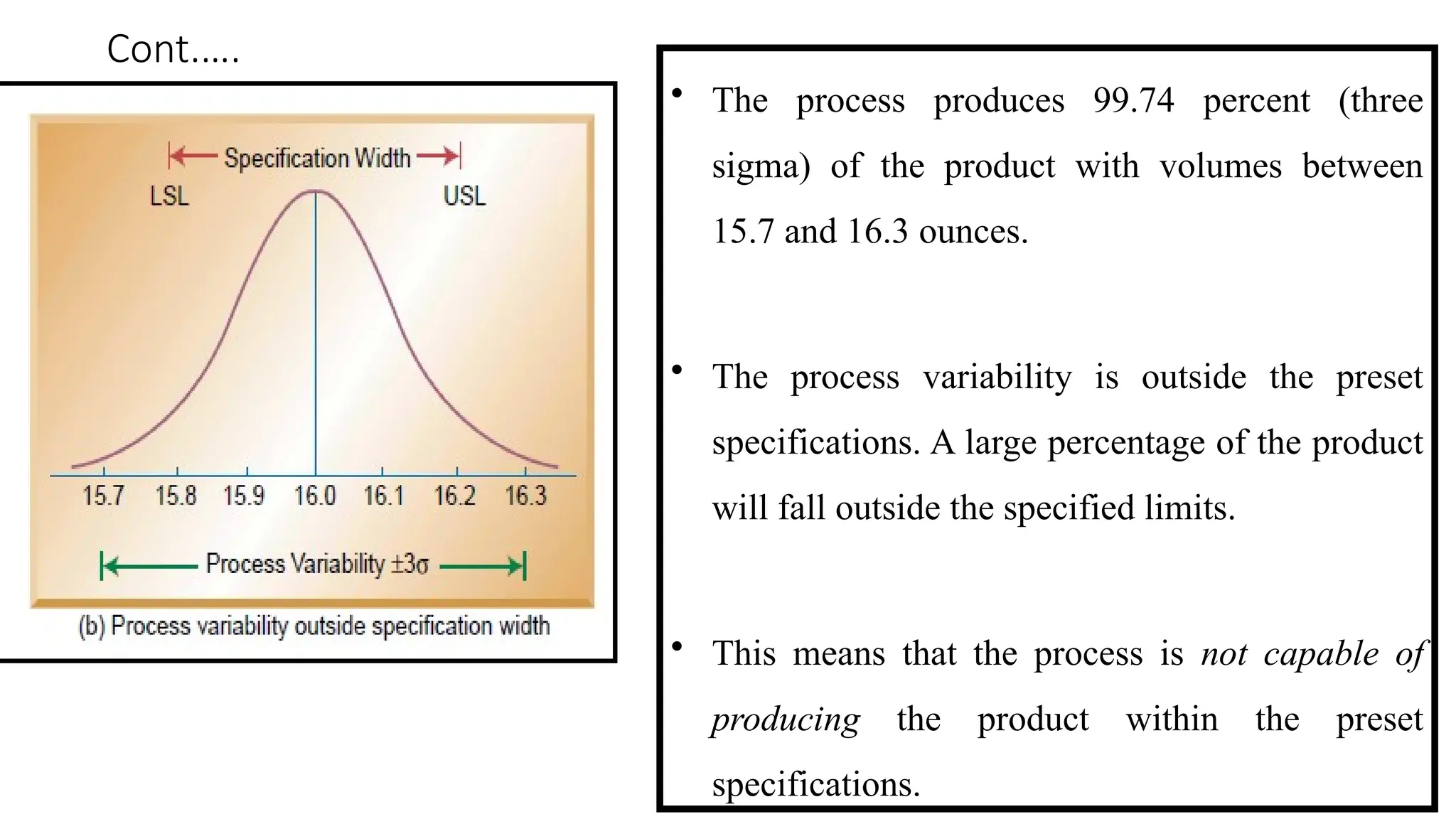

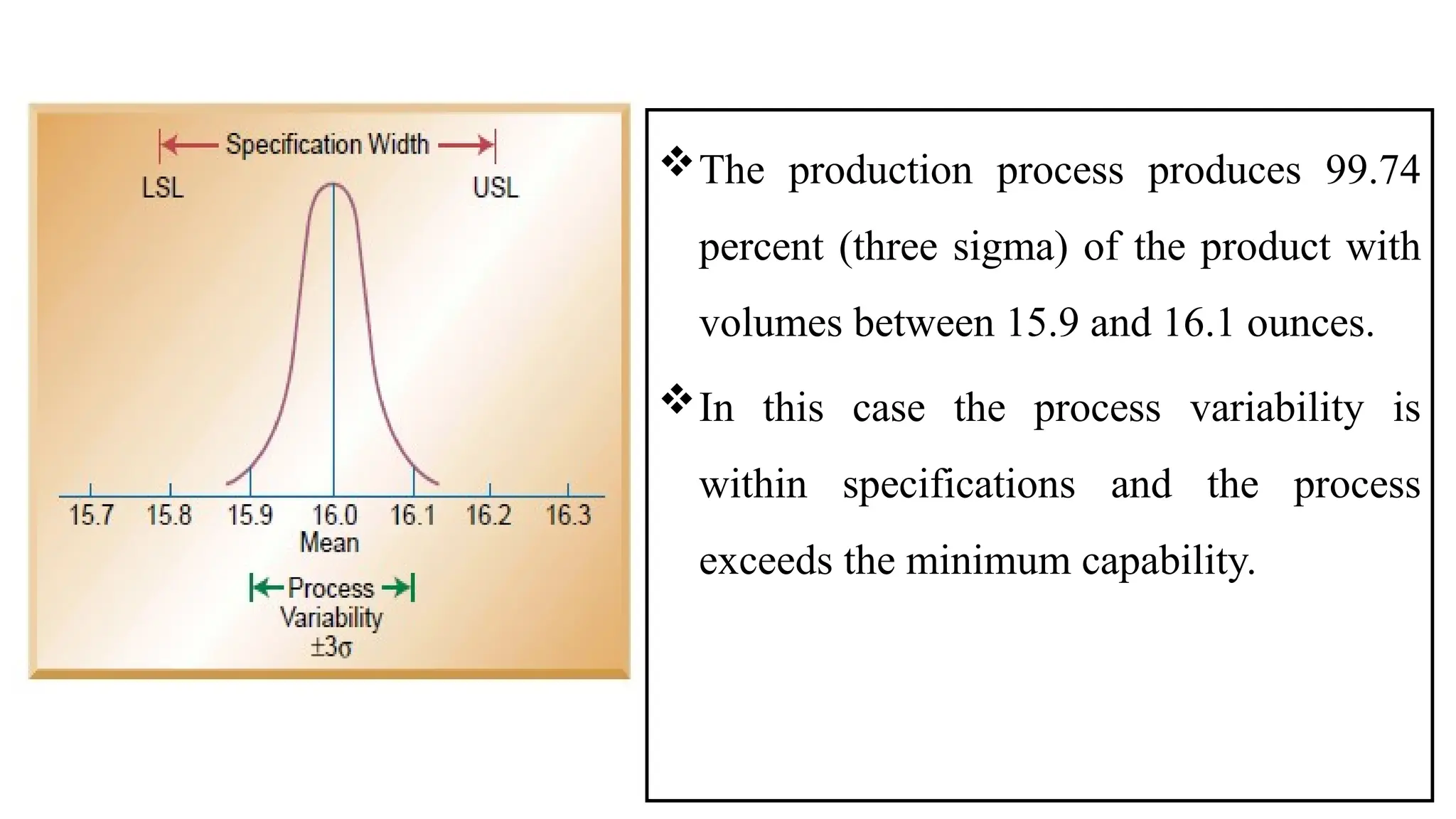

The document discusses statistical quality control (SQC) techniques, which include descriptive statistics tools and statistical process control (SPC) methods to monitor production processes. It outlines the concepts of common and assignable causes of variation, emphasizing the importance of maintaining control for process capability, which ensures that products meet preset specifications. Additionally, it describes process capability analysis techniques and the significance of process stability in evaluating production effectiveness.