Embed presentation

Downloaded 223 times

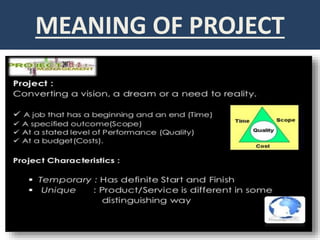

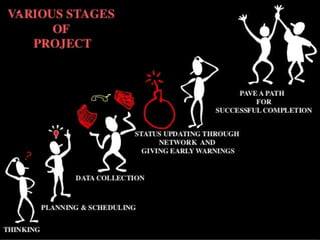

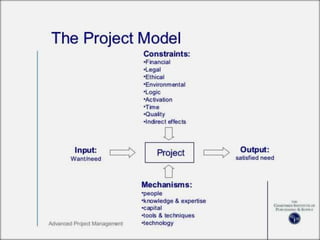

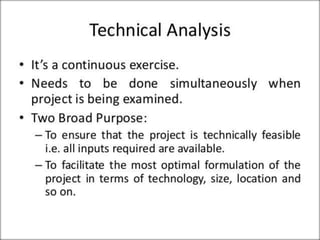

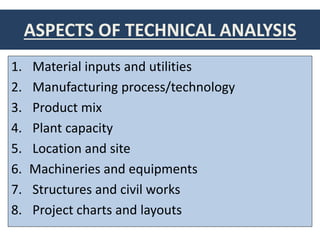

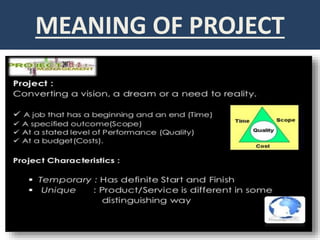

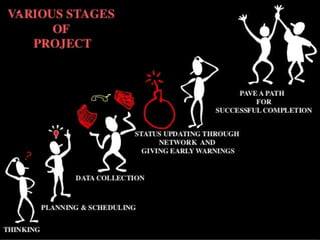

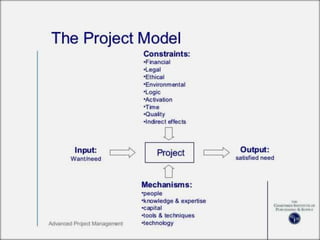

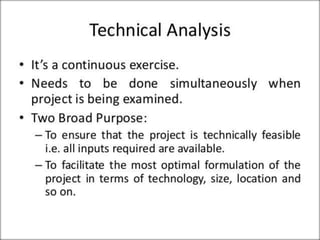

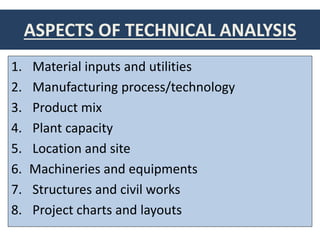

This document outlines the key aspects of a technical analysis for a project, including 8 areas of focus: 1) material inputs and utilities, 2) manufacturing process/technology, 3) product mix, 4) plant capacity, 5) location and site, 6) machineries and equipment, 7) structures and civil works, and 8) project charts and layouts. Each aspect is concerned with specific factors like defining material requirements, choosing an appropriate technology, determining production capacity, selecting a site, and developing project charts and layouts. The technical analysis will help define the project scope and provide a basis for detailed engineering and cost estimation.