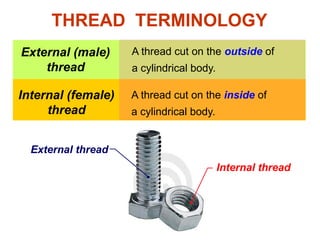

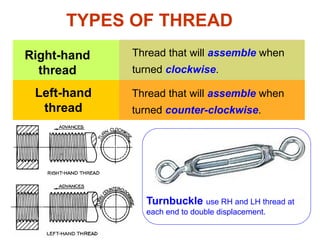

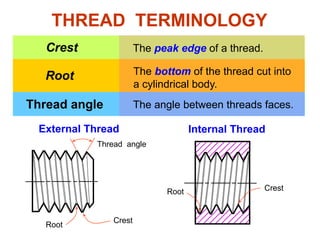

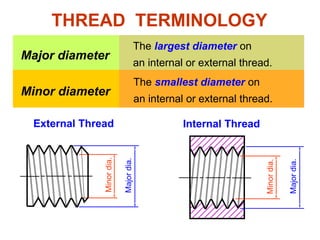

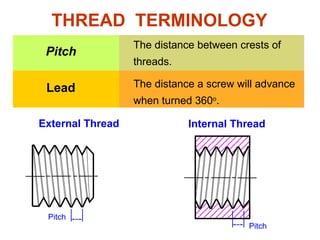

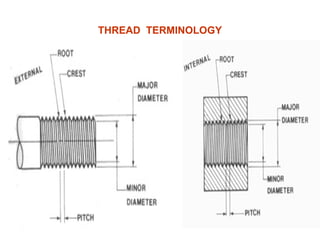

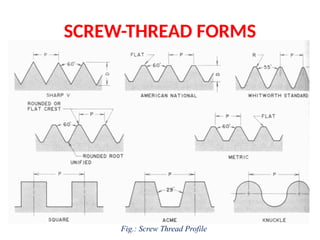

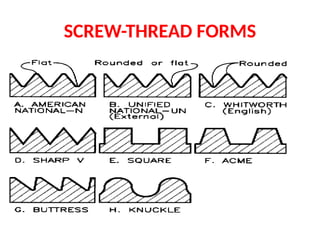

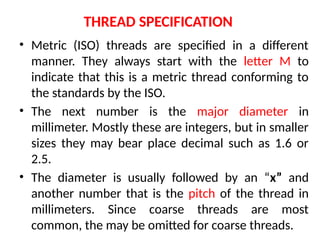

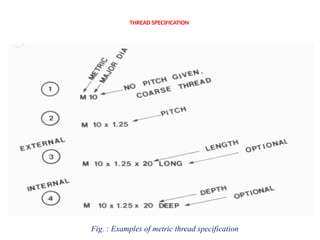

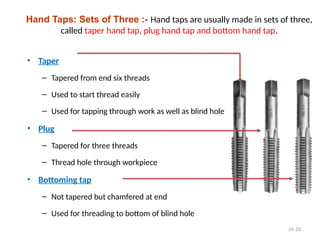

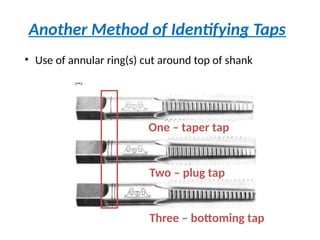

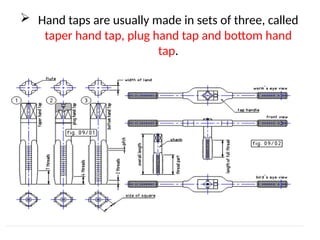

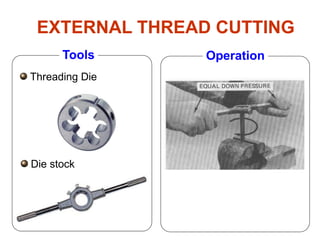

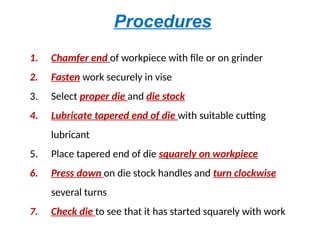

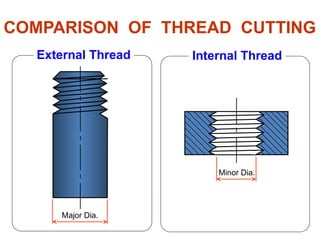

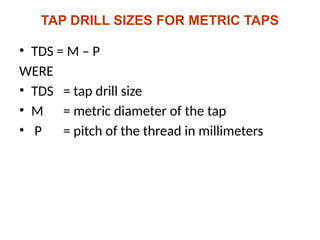

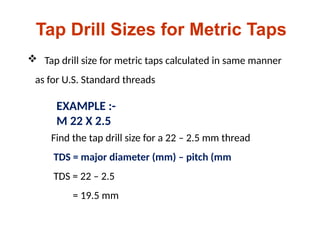

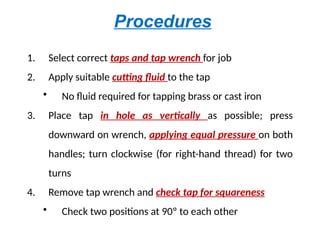

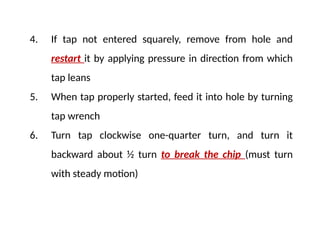

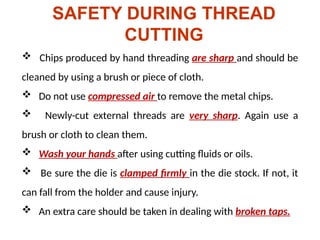

Chapter 5 focuses on thread cutting by hand, detailing the terminology and techniques used for internal and external threads using taps and dies. It explains the applications of screwed fasteners, the specifications for metric threads, and the features of hand tap sets, including taper, plug, and bottom taps. Additionally, the document outlines safety precautions and procedures for both external and internal thread cutting.